givemethebighammer

|

| posted on 25/7/03 at 11:20 PM |

|

|

help cam belt !!!

I needed to change the water pump on my 2.0l Zetec engine so, since I had to remove the cam belt to do this I thought I would change this as well.

(Never done this before)

So rotated engine so cyl nos 1 and 4 were TDC

locked can shafts with appropriate tool. locked crankshaft with appropriate tool.

Removed cam belt tensioner and removed the old cam belt.

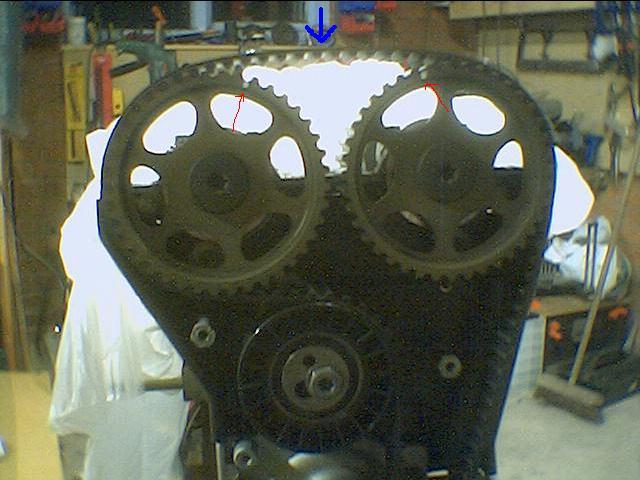

Before I removed the old belt I marked two points on the pullys (red arrows on the picture below)

and counted the number of teeth on the belt between them (there were 11).

When I came to refit the new belt, the same number of teeth were between the marks but the top section of the belt (blue arrow) seemed very slack.

Is this normal or do I have to loosen the pully bolts and move the pulleys to take up the slack ??

[Edited on 25/7/03 by givemethebighammer]

Rescued attachment slackbelt.JPG

|

|

|

|

|

Peteff

|

| posted on 26/7/03 at 11:32 AM |

|

|

On the sohc engine the pulley is keyed to the camshaft and there are already timing marks on the pulleys and block to line them up, are there any on

the head behind the pulleys. It looks like you have too much belt across the top. The counting teeth sounds a bit hit and miss. Any slack in your belt

should be taken up by the tensioner but if you tighten at that you will move something. It looks to me like you may be 180degrees out at the

moment.

Rescued attachment slackbelt.JPG

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Peteff

|

| posted on 26/7/03 at 11:44 AM |

|

|

Not a zetec expert.

I've only had dealings with one old Fiat TC engine before so I would try putting the old belt back on and look for timing marks. Someone who

works with Ford gear regularly will put us right if we wait long enough . I've done enough single cam engines to have an idea though. . I've done enough single cam engines to have an idea though.

Anyone nearby got the manual for you to look at ?.

yours, Pete.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

theconrodkid

|

| posted on 26/7/03 at 12:38 PM |

|

|

you are suposed to loosen pulley bolts then adjust tensioner,take it you got cam cover off and plate in slots in cams?

who cares who wins

pass the pork pies

|

|

|

givemethebighammer

|

| posted on 26/7/03 at 12:39 PM |

|

|

Both the cams and the crank were locked before the old belt was removed, so in theory the new belt should have fitted straight on (180 degress out or

not).

Think I may get my friendly local mobile mechanic to take a look to be the safe side

thanks

|

|

|

gjn200

|

| posted on 26/7/03 at 01:55 PM |

|

|

Try the old belt back on!! If its correct, wrong/faulty belt. If its the same a pulley and camshaft have moved.

<- Me!

|

|

|

theconrodkid

|

| posted on 26/7/03 at 02:56 PM |

|

|

yup could be wrong belt,if you put it tight across the pulleys and see if the tensioner pulls belt up tight,ive done loads of these and never had a

prob,gis a bell if ya want 0208 845 9784

who cares who wins

pass the pork pies

|

|

|

Mix

|

| posted on 26/7/03 at 06:20 PM |

|

|

Just been reading the Haynes manual. It states that when replacing the belt it should not be nessecary to adjust the pulley / camshaft orientation.

However a bit further on it says you can move the pulleys on the camshafts to achieve a taut belt run. It also says that the camshaft locking slots

are machined off centre and will be below the level of the cam cover joint when 180 degrees out.

Hope this helps, got my water pump this week so I'll be fitting that and replacing the cam belt soon.

Mick

|

|

|

givemethebighammer

|

| posted on 26/7/03 at 08:30 PM |

|

|

Been fighting this all day so I may be giving Mr Conrod a bell - thanks for the offer.

Here is what I did

1. Took rocker cover off

2. Removed all plastic cam belt covers

3. Rotated crank to 2nd timing mark

4. Inserted 5mm steel strip to lock cams

5. Locked Crankshaft with a small tool I made to jam the flywheel via the teeth.

6. Removed the tensioner

7. Removed the old cam belt

So far so good

I then replaced the old water pump..

checked timing marks to ensure crank not moved

Got the new belt, started at the crankshaft and worked anti clockwise keeping the belt taut. Fitted the new tensioner and spring. Rotated the

tensioner anticlockwise with an allen key and tightened the bolt. Made sure the cam belt was taut then slowly released the tensioner bolt to allow

the spring to tension the belt.

So far so good

It all looks good at this point, however when I remove the 5mm steel strip holding the cams the left hand cam (looking as the picture above)

"springs slightly clockwise producing the slack between the pulleys. Releasing the crank and turning it through 2 rotations does not

"settle the belt" .

I tried adjusting the pulleys, then repeating the 2 crank rotations but it concerns me that the haynes manual states that the 5mm strip should slide

easily back into the slots in the cams....it doesn't the left hand cam is always slightly out of alignment with the right.

By my interpretation of the haynes manual with the crank locked at TDC, the slots in the rear of the cams should be exactly horizontal such that the

5mm strip can easily be inserted ??

I have tried putting the old belt back on the result was the same so I think I have the right replacement item.

First time on a twin cam engine, don't really want to ruin it !!!!

thanks

|

|

|

givemethebighammer

|

| posted on 26/7/03 at 08:40 PM |

|

|

Any truth in the ?

Zetec, as are most ford 4 cyl's, a non-interferance engine, meaning for the

uninformed, that the valves won't contact the pistons (milled head, cam

change, domed pistons excluded...).

If so I will feel a little better knowing I won't completely ruin the engine !!!

|

|

|

Stu16v

|

| posted on 26/7/03 at 11:30 PM |

|

|

AFAIK the only 'safe' Ford engine was the Pinto. Everything else destroys itself if ever valves/pistons get out of sync.......

Dont just build it.....make it!

|

|

|

gjn200

|

| posted on 27/7/03 at 06:50 AM |

|

|

quote:

Originally posted by givemethebighammer

Been fighting this all day so I may be It all looks good at this point, however when I remove the 5mm steel strip holding the cams the left hand cam

(looking as the picture above) "springs slightly clockwise producing the slack between the pulleys. Releasing the crank and turning it through 2

rotations does not "settle the belt" .

repeating the 2 crank rotations but it concerns me that the haynes manual states that the 5mm strip should slide

I tried adjusting the pulleys, then easily back into the slots in the cams....it doesn't the left hand cam is always slightly out of alignment

with the right.

By my interpretation of the haynes manual with the crank locked at TDC, the slots in the rear of the cams should be exactly horizontal such that the

5mm strip can easily be inserted ??

I have tried putting the old belt back on the result was the same so I think I have the right replacement item.

First time on a twin cam engine, don't really want to ruin it !!!!

thanks

Ahhh! If its the exhaust cam that moved this is exactly what my nissan did, Solution ( as per nissan workshop manual)

Set up inlet cam to mark

Set exhaust cam to mark (will spring back)

Set crank to mark

On the exhaust cam there was some flats, hold with adjustable spanner and turn to mark

put on belt, ensure crank pully to exhaust cam pulley is tight (number of teeth was given) and correct teeth between cam pulleys.

Tighten tensioner.

Hope this is of some help

<- Me!

|

|

|

theconrodkid

|

| posted on 27/7/03 at 07:19 AM |

|

|

ah you took the locking plate out of cam,the cam will move cos of valve spring force,the belt wasnt tight enuf,thats why you have free spinning

pulleys on the cams,lock it up again,loosen pulley bolts,tighten belt realy hard then let it slip back to a reasonable tension then tighten cam pulley

bolts

who cares who wins

pass the pork pies

|

|

|

givemethebighammer

|

| posted on 27/7/03 at 11:25 AM |

|

|

Thanks so the stuff in the hayes about being able to easily slip the locking tool back in to place is c**p ?

I will have another go at this later

|

|

|

zetec

|

| posted on 27/7/03 at 04:13 PM |

|

|

I did the same as you marking the belt and counting teeth. I have changed 2 Zetec belts now and the second was slack between the two cam pulleys,

don't think as bad as in your picture...I would have thought if the teeth are the same pitch as the original, and has the same number of teeth

then as long as you have the same number between you reference point you can't go wrong. Might be worth fitting the belt, letting the tensioner

take up the slack, gently turn the engine over by hand a couple of times then recheck the tensioner.

Good luck! It will be worth the effort.

|

|

|

givemethebighammer

|

| posted on 27/7/03 at 07:57 PM |

|

|

Thanks folks

I guess my real problem is not knowing what it should look like !!!. All well and good following the haynes manual but you could still end up doing

something slightly wrong. What I intend to do is have another go following the various advice given here, then get our local mobile mechanic to pop

round for half an hour to check my work. Might cost me £20 but this way I will know for next time !!!

Once the cam belt is done, it's change the sump and pickup. Finish welding the engine mounts, bolt on the gearbox and in it goes

..............

thanks again

|

|

|

givemethebighammer

|

| posted on 28/7/03 at 08:55 PM |

|

|

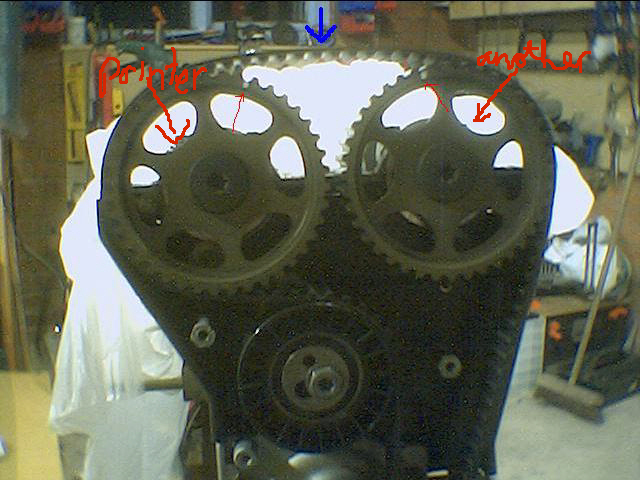

Think I got it !!!! few hours this evening following everyone's advice and the whole setup looks and feels much tighter.

See pic attached; belt between pulleys is now tight and slots on back of cams line up when crank is at TDC (not perfect, but only slightly out due to

valve spring pressure)

thanks again

Rescued attachment cambelt.jpg

|

|

|