alexdj125

|

| posted on 17/2/08 at 02:59 PM |

|

|

Know much about overheating?

HI all, got to ask about this as its starting to annoy me! my crossflow seems to run nice and cool for about 45 mins, and then the temp starts to

climb up to the 100 degrees mark. I have an ally header tank which when cool is about 1/2 full, and when the engine is up to temp it fills up

completely, but the problem is that it doesnt seem to go back in to the engine when it cools. I think this is because the header is at the same

height, or maybe slightly lower than some of the coolant pipes and so does't get sucked back in properly-if you see what I mean. Anyway, just

wondering if anyone had any ideas of how this can be solved without moving the header tank as it is as high as it can go!

Thanks, Alex.

|

|

|

|

|

RazMan

|

| posted on 17/2/08 at 03:15 PM |

|

|

It sounds like you might have air in the system, especially if the level doesn't drop when it is cold.

Have you tried putting a small bleed hose in the highest part of the system (possibly the stat housing) running back to the header tank?

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

r1_pete

|

| posted on 17/2/08 at 03:28 PM |

|

|

The pressure relief cap, presumably on your header tank should be the highest point on the cooling system, otherwise you will not completely fill the

system, and create ait pockets in higher points on the system.

As above, the high point on the engine should also have a vent back to the expansion tank to relieve air pockets, remember with air and coolant, you

cant force air downhill.

|

|

|

alexdj125

|

| posted on 17/2/08 at 03:55 PM |

|

|

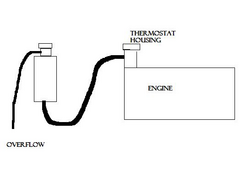

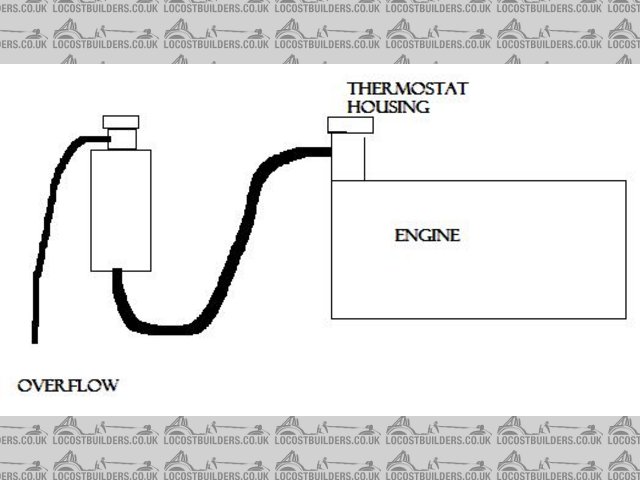

Thanks for the reply but I'm still slightly confused. so I drew a picture. The thermostat housing has a normal non pressure release cap on it and

a small pipe going from what would have been the overflow nozzle to the bottom of my header. The header then has a pressure release cap to an overflow

which just dribbles on the floor. Is this wrong?

Thanks, Alex

Rescued attachment cooling.jpg

|

|

|

nitram38

|

| posted on 17/2/08 at 04:20 PM |

|

|

Put a pressure cap on the original engine position. Attach the overflow to a simple plastic container, open to the air.

The plastic container should have some water in it and the overflow pipe should be below the surface, preferbly near the bottom of the container.

You can get the purpose made containers on some older cars.

You should fill from the original thermostat housing.

You seem to have misunderstood how this works and you are not purging the engine of air.

Modern car's header tanks are plumbed as part of the circulation circuit.

The bottle, normally nylon as a pipe from the bottom that tee's into the return from your rad.

A smaller pipe then comes from the highest point on your plumbing on the engine output side of the rad, sometimes from multiple points.

I have one from the top of my rad and engine head that tee just before going into the top of my expansion bottle.

[Edited on 17/2/2008 by nitram38]

|

|

|

alexdj125

|

| posted on 17/2/08 at 04:28 PM |

|

|

thanks, sounds like if I swapped the pressure cap on the header tank with the non pressure from the thermostat housing then this would do the same, as

the header would then be non pressurised and open to the air. right? I think I may put in a bleed nipple on my radiator top hose as its quite high and

I suspect air gets trapped in it.

|

|

|

nitram38

|

| posted on 17/2/08 at 04:41 PM |

|

|

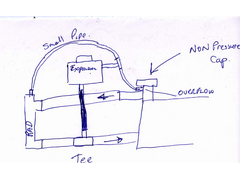

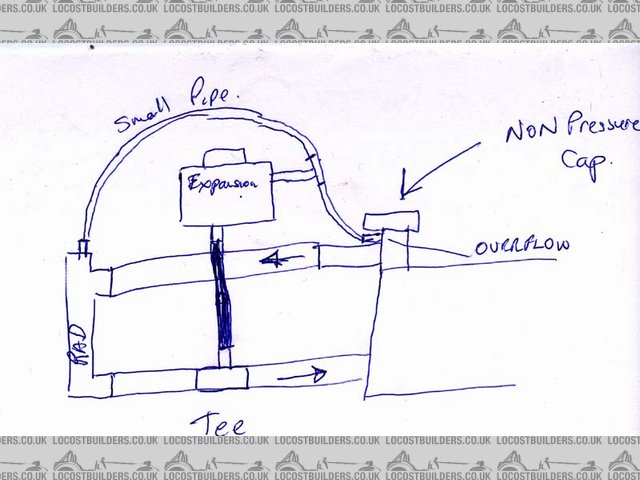

The way you suggest will work. but was superceeded by the more modern and reliable set up.

Your system will constantly lose water through the overflow into the container when the engine is hot, but draw it back in as it cools.

It would be better if everyone adopted the newer setup as it is lower maintenance, but more importantly, constantly removes air from the cooling

circuit.

Here is a quick sketch of the "ideal" setup.

As long as the bottom hose is smaller than the rad hose and the top hose is smaller still, you will get a small but constant flow of water through

the bottle which will remove the air.

Rescued attachment crossflow water.jpg

|

|

|

alexdj125

|

| posted on 17/2/08 at 06:44 PM |

|

|

Brilliant, thanks so much for your help, I'll start chopping in to hoses tomorrow, sounds fairly straightforward!

Thanks, again, Alex.

|

|

|