Well I never considered this optoin and after reading the other topic I am convinced. Just want to understand it properly. Correct me if I am wrong.

The de dion tube is suspended by four linkage arms connected to the middle of the chassis( actually behing seat) hence good power transfer and less

hop!? Plu sit sort of acts as a roll bar ?

Problem is how to connect the de-dion tube to the rear hubs??? I am not building a 7 type and I was going to use X1/9 rear hubs which are basically

front hubs. So question is how do I fabricate something to attache the de-dion, calipers, and linkages to the hub. I am sticking with FIat std as I

already spent £*** on wheels to suite. I can't think of any other rear wheel drive fiats?!

as far as i know, dedion uses a 5 point setup exactly the same as a live axle, the only difference being the diff is not part of it, and hence the

dedion tube is bent behind the diff.

quote:

Originally posted by alainmengoli@hotmail.com

I can't think of any other rear wheel drive fiats?!

You could try adapting a Dedion rear end off an Alfa as these have the hubs already sorted for you, and your wheels will still fit. I've got one

in the garage that I've gas axed the forward facing arms off, I'll get a photo at some point and put it in my archive so you can see what

they are like. They come with a Watts linkage already attached, but you'll have to sort the brakes, as the Alfa's are inboard.

Photo now uploaded.

[Edited on 23/6/04 by Tblue]

I sold the last of a long line of X19's to start my locost. The rear wheel bearings are a MAJOR hastle on an exxie, make sure yours are OK before committing your self.

sounds good please sen me some pics or email me

I am guessing your boxer already has inboard brakes, my old ti certainly did.

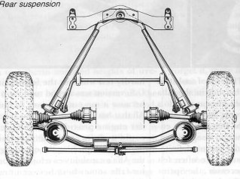

I have a drawing of the Guilietta rear end

Rescued attachment int_susr.jpg

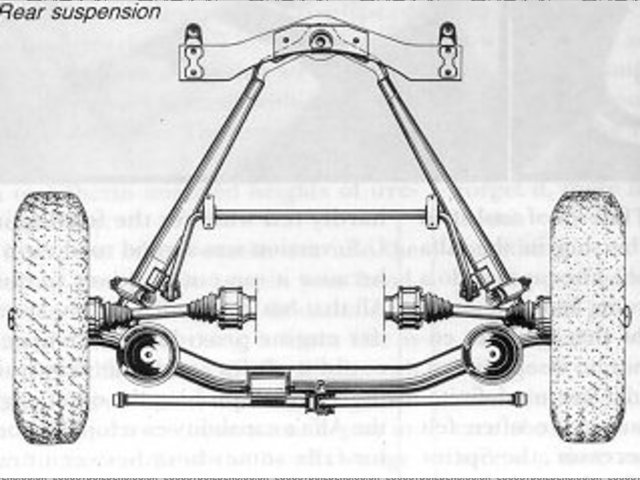

..and one showing its placement

Rescued attachment trans.jpg

Ignore the fact that my car is a middy and just note that I am using mcphereson strut style hubs coupled to a 3" 16ga deDion tube. The hubs have

been rotated 90 degrees...

I believe that the X1/9 hubs are similar to mine?

With access to a mill, the big ears should be cut off the hubs and holes tapped to allow the hub to bolt directly to the deDion endplate. Could save

several kilos that way.

quote:

Originally posted by sgraber

Ignore the fact that my car is a middy and just note that I am using mcphereson strut style hubs coupled to a 3" 16ga deDion tube. The hubs have been rotated 90 degrees...

I believe that the X1/9 hubs are similar to mine?

With access to a mill, the big ears should be cut off the hubs and holes tapped to allow the hub to bolt directly to the deDion endplate. Could save several kilos that way.

Thanks,

It could be more clever. I still haven't solved the parking brake issue. Although it's simply a matter of locating a bracket in the proper

position... Too lazy to figure it out I s'pose.

The entire assembly is pretty stout. Although I see that a triangle brace could be added to make it even better.

Here is a shot of the assy on the car. and it should be noted that the caliper must be unbolted to bleed the brakes. Not the best there either. Like

I said before, the idea is sound, my particular solution is so-so. I have some better ideas to solve it. I am sure that once you see this you can come

up with a better solution too.

You can check out this July 2003 archive page of mine for more info. Shows the deDion while under development.

http://www.newtier.com/graber/mid-engine/Rear_Drive_Cradle/index.html

Also don't miss the image gallery at my website.

Thos epics are great. I like the way you cut the uprights to fit them in which is my main problem. I am using fiat x1/9 rear uprights and their a nightmare to have the bearing changed. No one seems to know aht to do with them as if the bearings were pressed in but there is evedence of a large inverted bolt but no nut? . I am actually thinking of casting some one offs and it is actually very cheap. I was qouted £15 per hub using high quality steel that can be machined. hence with the new bearings and machinning I reckon a pair will cost only £90 not bad for one offs. Might be interested to if it is worth designing a pattern for the locost?????? hmmmm...

Alain,

You may have already come across this from other threads but my website has some information on the de-dion axle at

this webpage.

Please feel free to email me if you want any more information or guidance.

Cheers,

Craig.

Craig, that is a great website! I wish I had had that available before I built mine.

One thing you could go into greater detail on is how to align the hub carrier plates via a jig/fixture.

Craig,

That's all straight off the locost cdrom! is it copyrighted? My copy says copyright David Dunn 2002

Ned.

Ned,

I don't have the Locost CD-ROM but some guy sent the drawings etc to me a while back. If you see my website you will see the disclaimer at the

top of the page which reads:

quote:

Note from webmaster: The following information was obtained from a third party who I would be happy to acknowledge if I could remember who it was. I believe the design is originally from MK Engineering but I understand that they no longer manufacture this item so I hope they don't mind me publishing the design here. Please let me know if this is a problem and I will remove the material immediately.

was thinking of making a hub similar to that of the sierra but using the x1/9 bearings. But I still havent figured how the hell you take them out?Any help welcom.

general rule of thumb, you throw away the old hub carrier and buy a new one. The rear wheel bearings really were the exxie's achillies heel

Do any of you think I can use Ford bearing with my Fiat parts? Or maybe machine it to fit?

It's not the bearings themselves which are the problem, its when they finally give up the ghost, you have to replace the hub carrier as well. A

few years ago there was an engineering company that did an exchange scheme for the carriers. A look on the X19 owners club site might be useful

http://www.x1-9ownersclub.org.uk/

what about using the ford parts and redrilling the holes t osuit fiat stud patter?

why not use uprights from a different fiat/lancia/alfa? It's onlu the exxie that has the problem, I know that the uno uses 8.9" discs at the

front. I even have a 1976 fiat 128 which needs a reincarnation!

Rescued attachment 128.jpg

and these two until recently

Rescued attachment DCP_0169.JPG

Might be difficult, most redrillings are done at 45` to the original holes but the sierra back hubs have a hole in this position each side for accessing the hub mounting bolts . I think the remaining area left at say 20` would be marginal for strength. Anyone else?

quote:

Originally posted by sgraber

...and it should be noted that the caliper must be unbolted to bleed the brakes.

quote:

Originally posted by sgraber

...I am sure that once you see this you can come up with a better solution too...

quote:

...Also don't miss the image gallery at my website.

Regarding Remote bleeders for the rear calipers...

but there is still the matter of a small pocket of air that remains trapped when the calipers are bolted in place... Wouldn't this always be

there even if remote bleeders were used?

[Edited on 7/16/04 by sgraber]

You posted just as I posted...  Thanks for the compleements.

Thanks for the compleements.  Building cars sure is fun!

Building cars sure is fun!

[Edited on 7/16/04 by sgraber]

quote:

Originally posted by sgraber

...but there is still the matter of a small pocket of air that remains trapped when the calipers are bolted in place... Wouldn't this always be there even if remote bleeders were used?

quote:

Originally posted by alainmengoli@hotmail.com

Well I never considered this optoin and after reading the other topic I am convinced. Just want to understand it properly. Correct me if I am wrong. The de dion tube is suspended by four linkage arms connected to the middle of the chassis( actually behing seat) hence good power transfer and less hop!? Plu sit sort of acts as a roll bar ?

Problem is how to connect the de-dion tube to the rear hubs??? I am not building a 7 type and I was going to use X1/9 rear hubs which are basically front hubs. So question is how do I fabricate something to attache the de-dion, calipers, and linkages to the hub. I am sticking with FIat std as I already spent £*** on wheels to suite. I can't think of any other rear wheel drive fiats?!