Bonding Ali and steel?

jamesalx - 26/10/07 at 08:32 PM

Hi all,

Just planning my build and making all the necessary adjustments for my engine and gear box.

Have been reading some posts and wondered if you can make the frame out of alum…. Only joking

To strengthen the frame and make life easier, can you bond aluminium to steel? So instead on pot riveting the ali floor panes and internal panelling

you bond it to the frame strengthening it like a monocots.

Would this make any difference?

Could anyone recommend adhesives to use?

Thanks

nick205 - 26/10/07 at 08:42 PM

Most builders use a Polyurethane adhesive/sealant and rivets to fix ali panels to the chassis.

smart51 - 26/10/07 at 08:58 PM

You could probably find a special adhesive to bond ali to steel but you'd have to have the metal almost surgically sterile for it to work

properly. PU and rivets is a tried and tested formula. Stick with it (no pun intended)

dave-69isit - 26/10/07 at 09:08 PM

pollyflexlm will sort it got mine from screwfix

jamesalx - 26/10/07 at 09:09 PM

Was thinking somthing like this:

Bontech Metal to Metal 20 is a 2 component room temperature curing black colored odorless thixotropic odorless polyurethane adhesive. Bondtech Metal

to Metal 20 is a innovative system to glue metal panels.Specificly designed for the automotive aftermarket can easily replace traditional spot welding

technology.

http://www.bondtech.uk.com/cgi-bin/store/commerce.cgi?product=Automotive_Bonding&pid=12.htm

mark chandler - 26/10/07 at 09:32 PM

lotus bond and rivit, the shear strength when just bonded is okay until it starts to go then its like pulling off selotape. You need the rivits as a

physical barrier to stop this.

kb58 - 26/10/07 at 09:33 PM

Regardless of adhesive, always add at least a few rivets to the corners of the floor panels. There are many engine fluids that dissolve adhesives,

making it likely that the floorpan will rip off if running over something.

Hellfire - 26/10/07 at 10:18 PM

Using PU/Rivets will allow for a small allowance between the differing expansion properties of Aluminium and Steel whilst keeping them apart a little

to allow for movement.

Using a harder adhesive such as Araldite or other Loctite (2Pack) adhesives as used on F1 Racing Cars will only introduce additional stresses due to

thermal expansion. F1 cars are basically bonded using components of similar materials ie Kevlar/CF

Stay with the T&T way... PU & Rivets IMO

Steve

airframefixer - 26/10/07 at 11:09 PM

In short, yes it can be done. But its expensive and sensitive to anything other than a controlled environment. If your interested look up the

"FPL etch", "phosporic acid anodize", "AC-130 sol gel" pretreatment methods.

By simply abbrading aluminum and bonding using a suitable adhesive, your only going to get a realiable bond for a short period. Its all in the proper

preparation.

another vote for rivet bonding. If you can, try a two component polysuphide, thats whats used on aircraft.

Andrew

Doug68 - 27/10/07 at 04:25 AM

I'm thinking of using 3M VHB Tape in addition to

rivets.

The type of rivet used and the rivet spacing will determine whether the attached panel is actually adding anything structurally to the vehicle or not.

Go Google "structural blind rivet".

Here's a good source of information in riveting.

airframefixer - 27/10/07 at 05:27 AM

Doug

great source of information on that site. However it mainly applies to AD(2117) solid rivets and 2024-t3. Although these general guidelines apply, we

need better information that applies to the materials generally used in locost construction. I.e. cherry Q rivets and 5052, or cherry friction locks

and 6061-t6. I have yet to find a chart for bearing load per thickness and hole size for 6061-t6. Then add in .0625 mild steel from the standard

locost chassis. Any suggestions were we can find such info. Id like to know myself.

Andrew

Doug68 - 27/10/07 at 06:56 AM

I'll look into that, this is something I need to work out properly for my project.

I suspect most Locosts are using hardware store pop-rivets at 2" spacing and basically being a cosmetic attachment as a result.

Just getting people to go buy decent quality rivets for their projects I think would be win to start with.

procomp - 27/10/07 at 08:47 AM

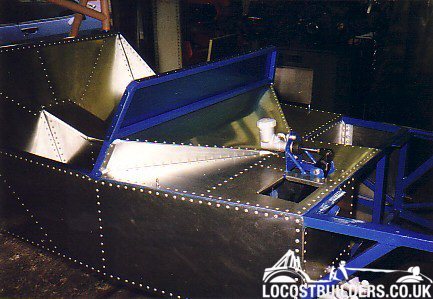

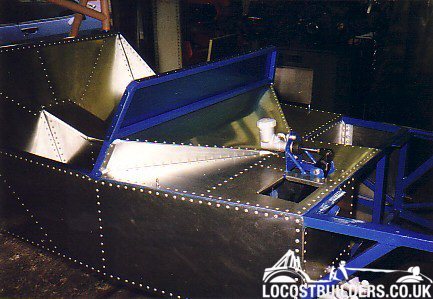

Hi i do love a good excuse to bring this photo out. 1" spacing and a verry good quality bonding sealer is the only way to go.

[img]http://locostbuilders.co.uk [/img]

[/img]

cheers Matt

Doug68 - 27/10/07 at 11:09 AM

Rivet PORN

Peteff - 27/10/07 at 11:30 AM

If the chassis is painted you are bonding to the paint not the metal so the quality of the paint becomes a factor in the strength of the bond

doesn't it?

jamesalx - 27/10/07 at 11:35 AM

What about using steel sheets and just welding/brazing them in?

Going to be too heavy?

What about using steel sheets and just welding/brazing them in?

Going to be too heavy?

I take it that making a hole into the frame every 1” sometimes on two or three sides is not going to weaken it?

jamesalx - 27/10/07 at 11:36 AM

quote:

Originally posted by Peteff

If the chassis is painted you are bonding to the paint not the metal so the quality of the paint becomes a factor in the strength of the bond

doesn't it?

I was going to bond then paint.

britishtrident - 27/10/07 at 01:32 PM

Problem with bonding is ensuring everything is clean and properly prepared.

Another of the problems with bonding is internal shear stresses at the ends causing peeling.

Lotus use a few rivets at the ends to prevent peeling but riving before the adhesive is cured will squeeze out the adhesive. If the adhesive film is

below a minimum thickness it will cause increased internal stresses and peeling.

Best bet is probably a combination of either adhesive tape or PU adhesive with rivets

[Edited on 27/10/07 by britishtrident]

[/img]

[/img]