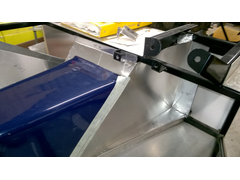

Rear corner alloy v3

Hi

Any suggestions or recommendations please for suppliers of aluminium sheet in Central/West/SW Scotland or can deliver here (either now or under

more normal situations)? Metals4U keeps popping up on the internet, anyone else? Aalco?

Old days I would be thinking of British Alcan or one of the Ayrshire stockholders.

I am looking to panel my Locost book chassis (already has a steel floor) in the standard manner.

Also am I correct I will need:

aluminium sheet commercial grade, modern equivalent to NS4 'half hard' grade (5251) and 18SWG thickness - 1050 H14 grade and 1.219mm thick?

And three 8" x 4" sheets of this (2,500mm x 1,250mm)?

Anyone got a sketch please of a cutting plan to maximise efficiency of material use? (any grain issues with cutting?)

Cheers

Mike

[Edited on 25/4/20 by Mike Wood]

[Edited on 25/4/20 by Mike Wood]

[Edited on 25/4/20 by Mike Wood]

I recently used metals 4u and was happy with their service.

I previously used Mallard Metals and was delighted with them, but not sure if they're still trading at the moment.

https://www.themetalstore.co.uk/products/aluminium

Been a very happy customer, used a few times for work stuff (handrail systems mainly) and always add a few extras for the garage. Great service, they

cut to size etc too, usually free (dead handy when I needed 25 x750mm 12mm steel pins, would have been a pain to do with a grinder!)

+1 for themetalstore

I'm only a few miles away from them so often collect but they do delivery too

Another vote for Metals4u from me.

Don't know how competitive they are on price but they have a good range and the service has always been good.

Thanks all for the help.

My question on what is the modern spec of the aluminium sheet was a bit mangled. Can I please confirm that the correct specification of 1.2mm thick

aluminium sheet for Locost chassis panelling is commercial grade aluminium sheet to 5251 H22 specification? And this is the modern equivalent of NS4

H3?

Cheers

Mike

Another recommendation for metals 4u here. Great service.

Thanks everyone for the very helpful supplier recommendations.

I think I finally have got my head round the specification required for chassis panelling: Commercial Grade 5251, H24 (temper type - half hard):

http://www.aalco.co.uk/datasheets/Aluminium-Alloy-5251-H24-Sheet-and-Plate_151.ashx

For people like me who read old books, 5251 is the modern equivalent to the previous NS4 grade. Commercial Grade 1050 not as strong as 5251 and not

preferred for chassis panelling.

For Locost racers panelling thickness according to the 2020 regs is minimum 18SWG (Standard Wire Gauge)/1.2mm:

https://www.750mc.co.uk/ugc-1/1/1/0/2020_final_regulations_-_locost.pdf

Best wishes

Mike

Hi,

I managed to pick up a full 8'x4' sheet from these guys in Dumfries for around half price as the corners were mangled, but almost all of the

sheet was fine. Was a while ago but always worth asking about seconds.

Ian

https://www.franklinsteelplc.co.uk/search/?s=Aluminium+sheet

NS4 is a tough alloy, great for floors but you may find difficulty in dressing it around the tubing if you use it for the panels. You will find 1.5mm thick 1050A easier to work and perfectly adequate.

Thanks John and Ian, that's really helpful practical advice.

John - I was struggling to get real information on what Ali sheet spec to use - 1050A but 1.5m thick sounds a very practical way to get a Locost

solution. Excellent.

Ian - great tip on seconds and also suggesting a Dumfries supplier.

Cheers

Mike

[Edited on 22/6/20 by Mike Wood]

[Edited on 22/6/20 by Mike Wood]

[Edited on 22/6/20 by Mike Wood]

You're very welcome Mike. When you come to tapping the sheet around the round tube use a wood or nylon chaser between the hammer and the aluminium to avoid marring the surface. Shrinking is necessary round the internal bends and you will find the aluminium will be more compliant if you warm it up a bit. You don't have to go to annealing temperatures. Metal moves slowly so work progressively and gently encourage rather than heavy blows. You'll soon get the feel for it.

quote:

Originally posted by Mike Wood

Thanks everyone for the very helpful supplier recommendations.

John

More useful tips - excellent, thanks. The 1050A you use - is it half hard H14 temper?

(http://www.aalco.co.uk/datasheets/Aluminium-Alloy-1050A-H14-Sheet_57.ashx)

I remember seeing a video of a Caterham chassis having the rear panel being fitted, with use of a candle and a blow lamp to assist yen forming over

the round tube.

Mcerd1 - thanks for the Aalco Glasgow tip, I'll contact them. Did you use 1050A H14?

Best wishes

Mike

[Edited on 23/6/20 by Mike Wood]

[Edited on 23/6/20 by Mike Wood]

quote:

Originally posted by Mike Wood

John

More useful tips - excellent, thanks. The 1050A you use - is it yeah half hard H14 temper? (http://www.aalco.co.uk/datasheets/Aluminium-Alloy-1050A-H14-Sheet_57.ashx)

Mcerd1 a thanks for the Aalco Glasgow tip, I'll contact them. Did you use 1050A H14?

Best wishes

Mike

Thanks John - you replied while I was correcting my typos in my post!

How is the Reliant Kitten project going?

Cheers

Mike

quote:

Originally posted by Mike Wood

Thanks John - you replied while I was correcting my typos in my post!

How is the Reliant Kitten project going?

Cheers

Mike

quote:

Originally posted by Mike Wood

Mcerd1 - thanks for the Aalco Glasgow tip, I'll contact them. Did you use 1050A H14?

If you can get it (and I can't any more) NS3 combines stiffness with malleability so compared with 1050A will give crisper folds. But harder to work and for panels I would still go for 1050A. It's cheaper as well!

quote:

Originally posted by John Bonnett

....I would still go for 1050A. It's cheaper as well!