I built mine... without success..

Regards,

Davide

[Edited on 9/9/03 by davimora]

what's the best way for build a jig for the 'L' front assembly?

I built mine... without success..

Regards,

Davide

[Edited on 9/9/03 by davimora]

Do you mean La,Lb and so on? If so, simply clamp the bottom piece to your work bench, get 3 pieces of 25mm tube and stack them up, put the top tube on

top of them and clamp it to your work bench so that it's parallel, and symetrical. Then lay the two compound angled bits in place and carefully

tack it all up.

Kingr

Is exactly what i did, but i think i measured something wrong. I'll retry the next weekend.

Thank you very much,

Davide

quote:

Originally posted by davimora

Is exactly what i did, but i think i measured something wrong. I'll retry the next weekend.

Thank you very much,

Davide

Remember the book dimensions are wrong for this...

Have a look at Mark Allanson's photo archive...

There's a good photo of the front assembly...

Hope it helps

If you want any other photos of different angles etc - I have over 600 of the build so far!!

Bloody slacker...

I have over 2000......

(yeah I know....sad..... )

)

sry 2 bring this up again but, i have just made the jig which has come out well, however no matter what i do i can not get the "two compound

angled bits" at the right angles.

does any1 no a good way of getting the angles or something which along these lines

Thanks 4 ur time

Philip Moreton

Mike Laws has built a bunch of these cars, he builds the L assembly flat, mitering the longer chassis rails (J1&2, F1&2) to lean the L section at the proper angle.

quote:

Originally posted by I love speed :-P

does any1 no a good way of getting the angles

It was a few years ago that I built my first locost chassis (I'm buying one this time!) and the dimensions for this bit are completely wrong, which threw me when I dew it up on CAD and made a nice jig, only to find it didn't fit the car!!

quote:

Originally posted by Alan B

Bloody slacker...

I have over 2000......

(yeah I know....sad.....)

Seeing that the dimensions are wrong, can somebody enlighten us on what they should be. I started work on the front last night, and all looks good so

far!!! Am I missing something

If you make the front and the top wishbones to the book dimensions you will not get the castor angle of 5.? degrees without almost missing the fu

section with the top rear bracket. I am in the process of making a chassis with the front altered to rectify this and have moved the lb and fu rail

back another 25mm and altered the width of the bottom wishbone to suit.

[Edited on 30/3/04 by Peteff]

Hi Pete,

Wont it just be easier to build the nose as per book and move fu1 and fu2 to fit the suspension. Just an idea if you view the thread on concern of

front suspension. Looks like a couple of the guys have gone that route?

You could, but if the top wishbone is made to the book design then you will almost miss the front bracket instead of, or as well as, the rear one. I found it easier to work out and with my latest efforts I can make a simple jig out of threaded and flat bar to locate the brackets and get the angle right on both sides.

Pete,

In deviating from the book in terms of the bottom wishbone, do you know of any unwanted side effects, and have you remained with the book measurements

for the top wishbone, or has this also been adapted.....

Secondly in constructing the nose, what has been the horizontal distance from lc to ld you have used, as this distance determines the angles?

I've just been here....

I downloaded Macsorley's plans & had NO problem building using them. To put front suspension points on I used a simple jig, tacked lower

rears in place then fixed FU tubes to pick up upper rears nicely.

I then removed LA and LB (very front uprights) and retacked these with the front pickups in place & tacked them on too. The uprights had to move

in a bit.

This was all pretty straightforward once the jig was made. I repositioned the lower 10mm further forward of upper to correct castor. Check front

suspension jig pics in photo archive of "Bob C" to see how I did it - it may give you some inspiration (or not....)

Cheers

Bob C

I put an extra piece of rhs under the top rail to make it 25mm further back. I have altered the top wishbones from the book and am in the ongoing

process of jigging it. My rear bottom wishbone bracket is behind the fu section so the jig would not work with a bar through both at once

[Edited on 30/3/04 by Peteff]

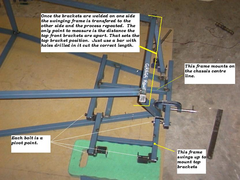

I forgot to put in that my chassis is 1" taller as well, sorry, so it slightly lessens the effect of putting the top la section further back. So

far this is what I've made for the suspension jig out of flat bat and threaded tube. I need a piece to join the rear suspension brackets together

and set them at the same distance as the front ones. The insides of the bottom wishbone brackets line up with the outside of the top ones and the

castor angle should come out as a result (if my design works)

Rescued attachment frontjig.JPG

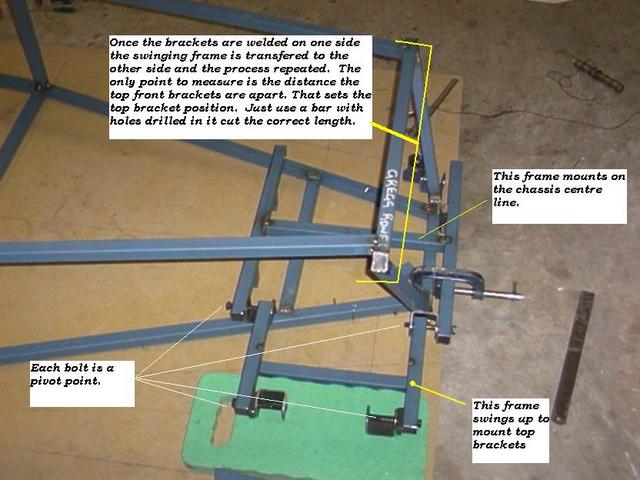

Chatting to some local boys, they have follwed the book really, and in creating their jig, they have raised Lc to 76mm to get the right angles for La

and Lb. Which is absolutely in line with McSorely's drawings. The postioning of FU1 and FU2 should be best left till a suspension jig has been

made as the attached photo, from a bloke in Australia. Hope that this helps all those who were initially baffled as I.

Rescued attachment Jig for front suspension.jpg

quote:

Originally posted by kingr

Do you mean La,Lb and so on? If so, simply clamp the bottom piece to your work bench, get 3 pieces of 25mm tube and stack them up, put the top tube on top of them and clamp it to your work bench so that it's parallel, and symetrical. Then lay the two compound angled bits in place and carefully tack it all up.

Kingr

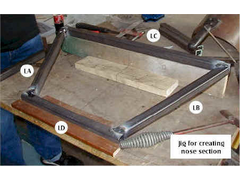

Hi davide

I have attached a photo of a Jig for using on the front assembly as per my brief description previously.

Cheers

Jayce

Rescued attachment front Jig.jpg

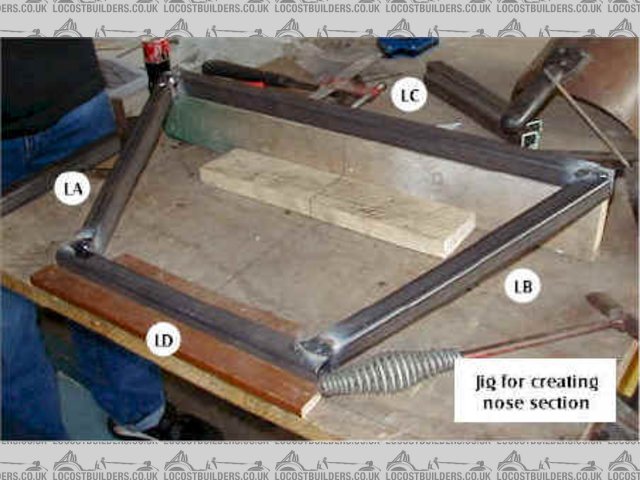

... very similar, but less tree wood!

Rescued attachment FrontPanel.jpg