Isn't the hole in a Cortina upright tapered?

I'm keen on working out how to do this so I can fit some wider wishbones easier, and play about with adjusting the bump steer

Thanks,

G

Does anyone know how this has been achieved?

Isn't the hole in a Cortina upright tapered?

I'm keen on working out how to do this so I can fit some wider wishbones easier, and play about with adjusting the bump steer

Thanks,

G

I assume by using this kind of thing:

http://cbradleymotorsport.co.uk/suspension-steering/steering/steering/track-rod-end-rose-joint-adaptor-kit.html

What uprights do you have? I'm currently in the process of making up a kit to convert the Rally Design uprights to use rod ends on the steering

rack to sell.

I was also thinking less than 1/2 the price of the CBradley kit as well!

I have proper 'ord fashioned Cortina uprights

What is different on the Rally Design uprights?

G

[Edited on 28/10/14 by Northy]

The Rally Design Uprights have a straight hole in the steering arm and then have a stainless steel insert with an internal taper to fit the smaller

RS2000 track rod.

I make all the parts individually so if you like I could design and make you up a set to fit a standard Cortina upright.

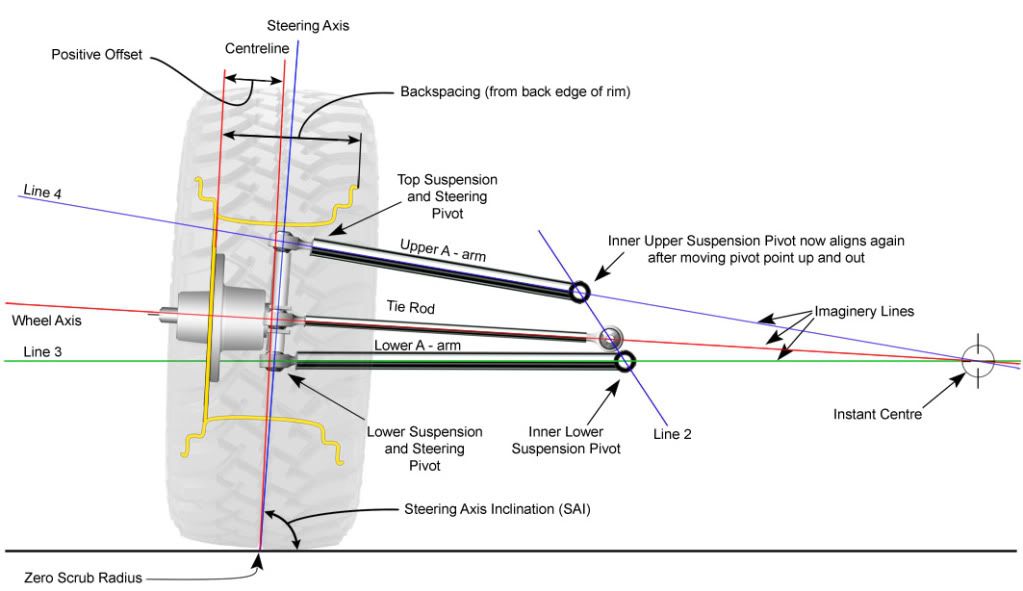

Int bump steer all to do with the inner joint position on the rack gear? Not sure what using a different joint at the steering arm will help?

quote:

Originally posted by coozer

Int bump steer all to do with the inner joint position on the rack gear? Not sure what using a different joint at the steering arm will help?

Thats it, nice picture.

I thought that the steering arm should be parallel with the bottom wishbone to give zero bump steer.

The top wishbone affects camber change?

So therefore moving the outer joint up or down could help bumpsteer?

G

See how it lines up with the axle centre line? The steering arm is already designed with that in mind so making sure the rack is at the correct height would be thee first step.

quote:

Originally posted by Northy

I thought that the steering arm should be parallel with the bottom wishbone to give zero bump steer.

The top wishbone affects camber change?

So therefore moving the outer joint up or down could help bumpsteer?

G

Both rack height and outer ball joint position effect bumpsteer. And both can be corrected.