Warped me bones. Fix or cry?

blueshift - 4/12/05 at 11:32 PM

Bugger. finished welding my top wishbones tonight (apart from some spots of dodgy weld that need grinding and going over), dropped them back in the

jig to find they're quite warped

the bush tubes are up to 5mm closer together than they should be, which isn't in itself the end of the world, but the warp has meant they're

not coaxial any more. With poly bushes I think they're too far out of line to be acceptable.

Photos: (more and high res ones can be found here)

So.. why did this happen? the tubes were a good fit before I started. too much heat? some other error?

And.. what now? hammer or stretch them back into shape? cold or heated? oven them afterwards? or just bin them?

I think I could get them back into shape with some threaded rod and washers to push the arms apart, but I don't know if this would weaken the

bones significantly.

I await any comments.

dnmalc - 4/12/05 at 11:47 PM

Scrap and start again I suspect that you did not weld from each side in turn and hence you have raised the temperature unevenly causing uneven

expansion side to side

Rorty - 5/12/05 at 04:58 AM

Over the hedge with them and start again.

I'm afraid that's no jig either. You'll need something more substantial than that if you want acceptable results.

Hornet - 5/12/05 at 08:17 AM

My first attempt ended with the same results as u. My second, I made a steel jig and secured everything in place so that when welded, would not warp.

Very happy with end results.

Cheers J

ayoungman - 5/12/05 at 08:48 AM

Use some studding to hold bush tubes inline. Also as before, secure arms so they cant move at all. HTH

James - 5/12/05 at 08:50 AM

Blueshift,

For what it's worth:

Weld the wishbone tubes on as one tube that stretches the entire length of the wishbone. Then cut out the middle section.

They have to stay parallel then!

Best to start with the bottom bones as then the middle section you cut out will fit the top bones (IIRC!).

HTH,

James

James - 5/12/05 at 09:10 AM

As for fixing/jigging the system so that the parts can't move- there's not a whole lot of point if you don't weld it properly.

If it's welded in such a way that there are internal stresses in the metal/assembly then however well the tubes are 'fixed' then as

soon as they're removed from the jig the assembly will go 'ping' and distort.

The best way is probably to do it with the single long tube (as in my post above) and then before cutting it out stress relieve you bones in the oven

(Mark Allanson did this).

You'll probably end up with striaghtest bones this way!

Cheers,

James

[Edited on 5/12/05 by James]

NS Dev - 5/12/05 at 10:53 AM

most of the wishbones you buy are like that. My Stuart Taylor wishbones are out by a similar amount and seem to work fine. Don't like them and if

I were making them they'd have gone in the bin but hey ho.

blueshift - 5/12/05 at 05:37 PM

thanks, all. BAH.

Am I right in thinking that if I make a sufficiently stiff steel jig that really nails everything in place, weld it in that, then oven the lot for a

couple of hours (500F hot enough?) it should come out of the jig and stay the same shape?

At least I found out on the top bones which I can replace the parts for without too much difficulty. the bottom bones have some custom laser cut steel

plate in done by my mate who since quit his job at a fabricators.. really don't want to cock those ones up.

[Edited on 5/12/05 by blueshift]

Sven - 5/12/05 at 06:03 PM

quote:

Originally posted by James

Weld the wishbone tubes on as one tube that stretches the entire length of the wishbone. Then cut out the middle section.

They have to stay parallel then!

I disagree, insofar as it HAVING to stay parallel. Latent stresses in the steel once the welding is complete will be released and still put it out of

line.

However, it would do the same job as better jigging, which, along with moving around while weldind, is the key to minimal distortion.

-Steve

Sven - 5/12/05 at 06:08 PM

quote:

Originally posted by blueshift

Am I right in thinking that if I make a sufficiently stiff steel jig that really nails everything in place, weld it in that, then oven the lot for a

couple of hours (500F hot enough?) it should come out of the jig and stay the same shape?

Not really. A very rigid jig and moving about with your welds, do a little here and a little there trying not to get too much heat into one area.

Also, try and do a bunch of tack welds on each joint before finish welding it, that helps.

In terms of stress relief, before taking it out of the jig put a torch to it to heat it up until it starts to discolour towards a dark red then let it

cool. This will require that you make a jig that can handle the high heat.

-Steve

Rorty - 5/12/05 at 09:31 PM

quote:

Originally posted by James

Weld the wishbone tubes on as one tube that stretches the entire length of the wishbone. Then cut out the middle section.

James I'm shocked!  How do you gut the section of tube out so the edges of the eyes are perpendicular to the bores?

How do you gut the section of tube out so the edges of the eyes are perpendicular to the bores?

I use several methods and jigs to make wishbones:

I usually start with a length of 50mm x 50mm x 3mm SHS and use a carpenter's marking gauge to score a centre line along one face. That line is

then common to all pieces of the jig.

I cut the SHS into suitable lengths and for smallish (Locost) size wishbones, make a T frame (rear wishbone jigs are normally a square or H shaped

frame).

If using a rod end at each pivot, I weld a simple tab with a hole in it at the appropriate position. The tabs start off as a length of 50mm x 6mm cold

rolled flat bar (nice square edges and no scale) and have the obligatory centre line scored along it. Once the tabs are cut to length, it's a

simple job to align the centre lines with the lines on the SHS and then use a set square to ensure they are square to the tube and tack them on.

After all the tabs are tacked on, stand the set square on the SHS and up against the faces of the tabs to make sure they have remained vertical. If

they've moved, adjust them gently with a hammer, making sure to bend them only at the welds. Fully weld the tabs and check them one last time.

To make a wishbone in the jig I go to my box of "weld bolts" (bolts only used for jigs that have been rendered useless by repeated high

temps – each has an identifying angle grinder groove across their heads) and smear a dab of high temp anti-seize paste on a few. I then insert the

bolts through the holes in the tabs and screw the ferules or sleeves onto them. All that remains to be done then is to cut and fishmouth the tube to

suit.

If there are to be bushes on the inner ends of the wishbone, I make a few more tabs and position them either side of where the wishbone eyes will be.

Obviously a bolt through the tabs isn't going to secure the eye concentrically, so I turn a brass bush to be a slip fit in the eye and have a

hole through it for the bolt. The centre lines on the flat bar and SHS are fairly accurate ways of aligning the tabs, but to be 100% sure in this

scenario, I usually pass a length of drill rod/silver steel/ bright bar through all the tabs and brass bushes etc. Don't use threaded rod for

anything like this. It's not accurate and it's undersized compared to the shank of a similar bolt. Each time you introduce a tolerance it

multiplies and you'll end up with another out of whack part for your car.

The jigs above are fine for one-offs (which most Locost builds will be), but the way I make permanent jigs for repeated use is to weld them up from

heavy steel plate or aluminium and then mill all the mating faces and holes on a NC mill. The accuracy can't be beaten and the heavy construction

helps conduct heat away evenly.

Just talking about heat, it's a good idea to relieve the stresses in welded jigs prior to using them and then checking them for accuracy again

when they've cooled down. Post heat-treating welded assemblies is difficult without the proper equipment, but just preheating the tube to 150°C -

200°C prior to welding will lessen the chances of it moving as it cools down. As pointed out by others above, careful placement of the tack welds and

balancing the welds will also help reduce uneven contraction. It's a bit like pattern tightening wheel nuts.

It's worth putting the time into good jigs as the results will pay off. You think nothing of spending hours prepping bodywork prior to painting,

so a little time spent on jigs shouldn't be ignored either.

Mark Allanson - 5/12/05 at 09:53 PM

quote:

Originally posted by Sven

quote:

Originally posted by James

Weld the wishbone tubes on as one tube that stretches the entire length of the wishbone. Then cut out the middle section.

They have to stay parallel then!

I disagree, insofar as it HAVING to stay parallel. Latent stresses in the steel once the welding is complete will be released and still put it out of

line.

However, it would do the same job as better jigging, which, along with moving around while weldind, is the key to minimal distortion.

-Steve

Sven,

James is quoting what I did, I left in the crntre section, blow torched the to just off luminescence and let them cool down in a hot oven overnight.

When I cut out the centres, there was no distortion at all, the cut was still the width of the hacksaw blade all around. I did make substantial steel

jigs which also helped.

Mark

02GF74 - 5/12/05 at 10:02 PM

I'm no expert here, in fact i can't tell if you gas or MIG welded them!

Did you tack weld them first? The way I would have donew it is put 4 tacks, 2 on each side then fully weld (MIG),

907 - 5/12/05 at 10:07 PM

Hi All,

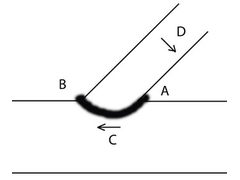

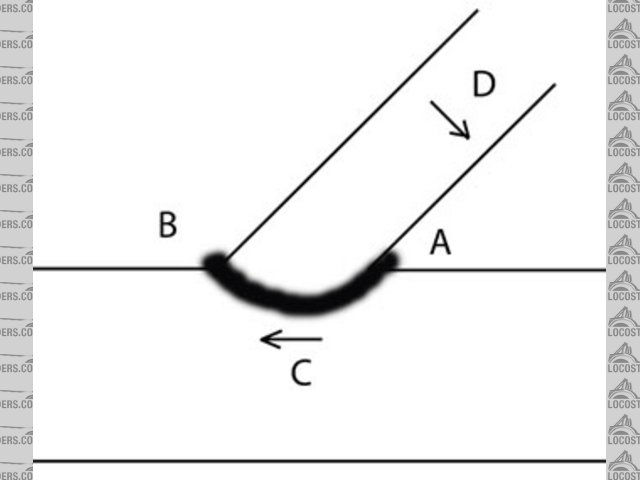

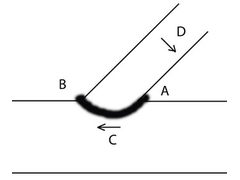

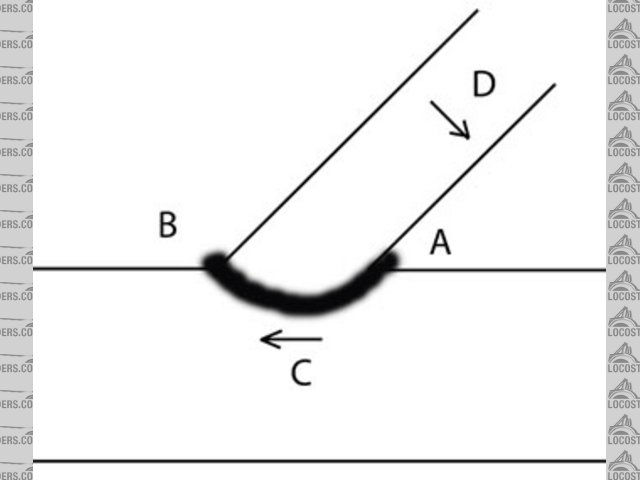

The pic below shows an unequal tee joint, similar to that on a wish bone.

When this type of joint is welded it will distort in the direction of arrow D.

I suspect this is what has happened in the case of your w/bone Blueshift.

The way to reduce this effect is to weld the throat (A) first, then in the

direction of arrow C and finish at B. Then the other side, from A to B again.

That's weld in three stages.

To rectify your w/bone Blueshift, leave the weld at A, then grind off most

of the weld from C round to B, both sides.

Use a piece of studding to spread your bush tubes apart to the correct dimension,

then reweld in the direction of arrow C. Allow to cool and remove studding.

Magic.

hth

Paul G

Rescued attachment pipe-joint-s.jpg

blueshift - 5/12/05 at 11:16 PM

Thanks all. must rush to bed now but have read all this with much interest. I knew you guys wouldn't let me down!

"I can FEEL myself getting smarter"

blueshift - 6/12/05 at 05:55 PM

Ok, I'm going to give type 907's fix a try. What's studding? threaded rod?

If that fails I shall endeavour to build a bombproof jig that I can fully weld then heat-treat the bones in.

[Edited on 6/12/05 by blueshift]

907 - 6/12/05 at 09:14 PM

quote:

Originally posted by blueshift

Ok, I'm going to give type 907's fix a try. What's studding? threaded rod?

If that fails I shall endeavour to build a bombproof jig that I can fully weld then heat-treat the bones in.

[Edited on 6/12/05 by blueshift]

Hi again,

Yup, studding = threaded rod. A length of m12 should do.

Just one thing; if you lay a straight edge on the bush tubes you will be able

to tell if one side has pulled more than the other.

If this is the case grind more weld off the side you want to pull back the most.

When a weld is formed the metal goes on in molten form. As it solidifies and cools, it shrinks.

The studding, when you open up the bone, will create tension. The welding will release

this tension so it should stay where it was set.

Good luck.

Paul G

Jeffers_S13 - 7/12/05 at 09:29 AM

What an ace thread !

blueshift - 7/12/05 at 06:22 PM

You're telling me, jeffers

I'll post back with my results when I get off my arse and try it.

blueshift - 29/12/05 at 03:04 PM

for info, I thought to myself "hmm, if heat can get the stresses out maybe I don't need to re-weld them at all.. just force the bush tubes

to the right positions then heat-treat it"

I tried that; heated them in a hot oven then had a go at them with my puny blowlamp. I think it was much too puny though, couldn't get anything

approaching glowing, guess I need a forge or an oxy torch. I thought about possibly building a custom ultra-high-temp oven for heat treating but have

shelved that idea for now.

I also noticed that the tubes are twisted off where they want to be as well as bent inwards, so even if I could get the arms further apart they'd

still be off just with the threaded rod stretch method.

I keep changing my mind but at the moment I'm thinking I'll make up a straight jig just to hold the bush tubes in the correct alignment, get

some brass bushes made up and use solid rod as per Rorty, and try and force the tubes into the jig, then find a company that has proper high-temp

stress relief equipment and see if they'll put it in for beer tokens.

I know that's an ugly work-around kind of fix but it should be ok, should it not?

If as I think is likely I can't force the tubes into the jig, I could cut one of the welded joints mostly/completely off, put it in the jig and

re-weld.. then get it heat-treated.

When all that fails spectacularly I will stamp my little feet, buy new parts, build a proper jig and, hopefuly, get that properly stress relieved

before taking it out after welding.

That said, if I weld it in a proper jig perhaps the wishbone will be true enough without heat treatment..?

And are heat-treating ovens the kind of thing that are common in the fabrication world?

Comments on my stupidity are welcomed.

I just don't want to give in and have to pay a pro to make them

907 - 29/12/05 at 09:38 PM

If you want to bend and twist your bush tubes back into position you'll need some serious heat.

Oxy / Act or a carbon arc torch and heat to cherry red all round the circumference of the tube,

just below the bush tube.

Bone in the vice, big long bar in the bush tube.

Forget the cooker oven and butane blowlamps. They are not hot enough.

To give some idea of temperature, steel melts at 1420 deg C

Hot working is done at 900 to 1200 deg C (cherry red)

Stress relieve is done around 600 to 700 deg C

And to give you some idea, if you get it to go dark blue, that's only 300 deg C

It sounds like they are out of line in all directions so maybe you should think of making a proper jig,

one that you can weld the whole thing up in, (not just weld one side,) and start again.

Sorry.

Paul G

blueshift - 30/12/05 at 01:59 AM

yeah, that's the conclusion I'm reluctantly coming to.

I can't think how to make a jig that I can easily locate the balljoint tube in and yet get around to weld it all. however I don't think I

need to, I have my original (crappy for welding but accurate for fitting) jig that I can fit and tack the bone together on, then put it onto a strong

jig that just locates the bush tubes. slight wonkiness of the balljoint tube is not critical I think.

907 - 30/12/05 at 10:14 AM

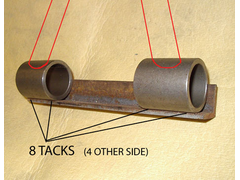

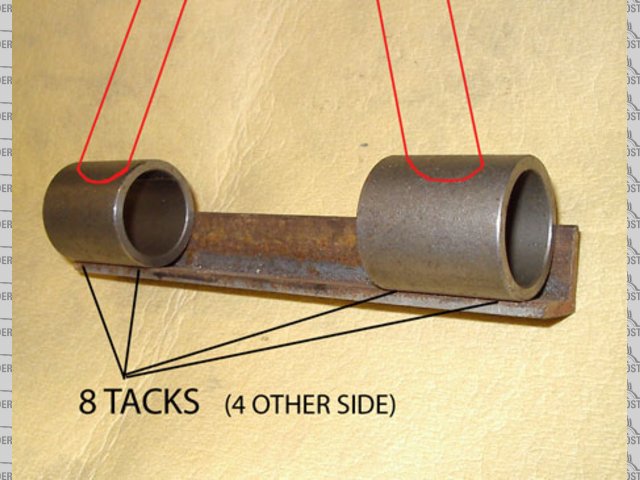

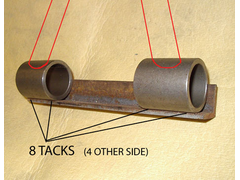

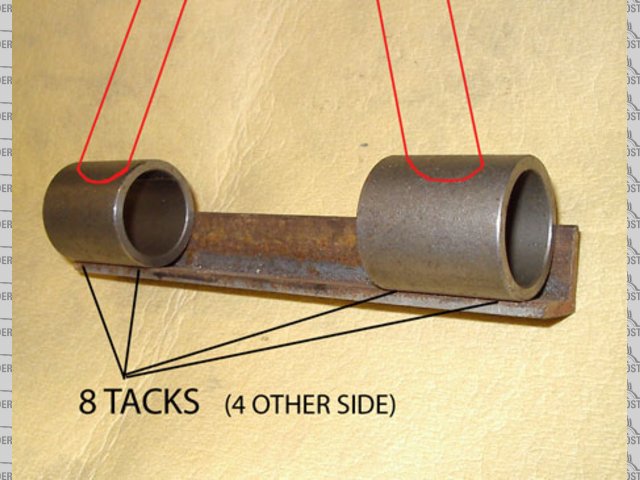

O.K. Plan D,

Carefully grind off the weld and remove the bush tubes compleatly.

Clean them up, (or use new ones)

Tack them into a makeshift vee block at the right spacing.

(in the pic I'v used a bit of angle, but you could use two lengths of pipe welded together, or three bits of box)

Sit your w/b on the top (red lines) and tack & weld.

Let it cool and cut through the tacks and remove the angle / pipe / box.

Paul G

Rescued attachment vee-block-s.jpg

blueshift - 30/12/05 at 06:33 PM

Cor, that's a clever idea. thanks.

James - 30/12/05 at 11:07 PM

quote:

Originally posted by Sven

quote:

Originally posted by James

Weld the wishbone tubes on as one tube that stretches the entire length of the wishbone. Then cut out the middle section.

They have to stay parallel then!

I disagree, insofar as it HAVING to stay parallel. Latent stresses in the steel once the welding is complete will be released and still put it out of

line.

-Steve

That's why my second post talks about the heat/stress relieving the way Mark Allanson did- then it won't jump out of allignment when the

middle section is cut.

quote:

Originally posted by Rorty

quote:

Originally posted by James

Weld the wishbone tubes on as one tube that stretches the entire length of the wishbone. Then cut out the middle section.

James I'm shocked!  How do you gut the section of tube out so the edges of the eyes are perpendicular to the bores?

How do you gut the section of tube out so the edges of the eyes are perpendicular to the bores?

Careful use of hacksaw, barstard file and set square!

They're good enough for my Pinto engined piece o' junk!

Cheers,

James

How do you gut the section of tube out so the edges of the eyes are perpendicular to the bores?

How do you gut the section of tube out so the edges of the eyes are perpendicular to the bores?