I'm fed up of working on the floor so I designed these

rodders - 27/1/09 at 02:43 PM

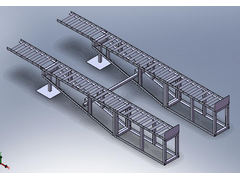

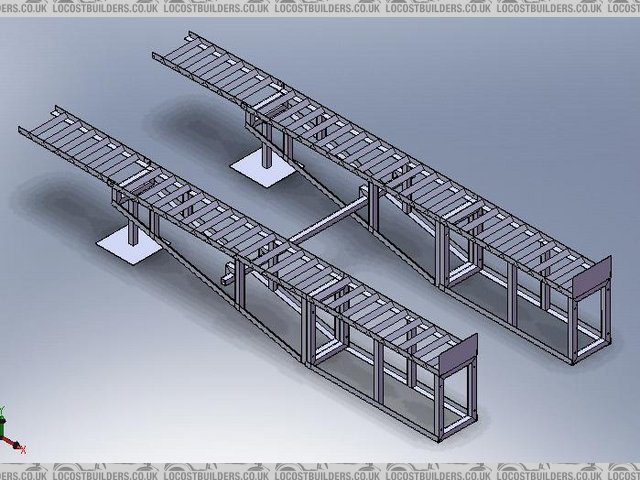

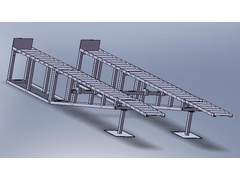

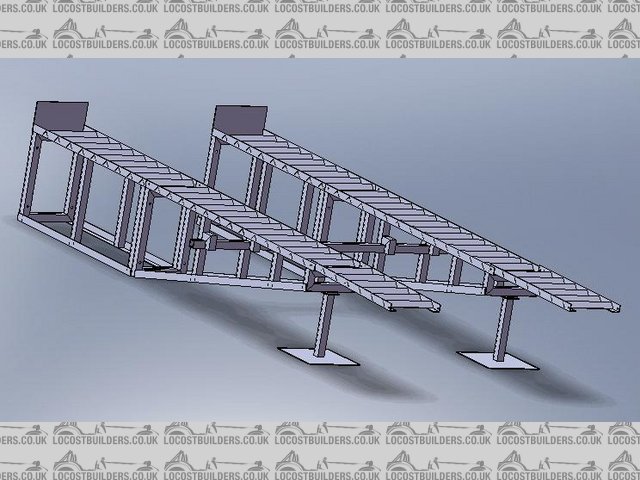

Having had enough lying on a cold and often wet floor to do work on my cars so I decided to look into some ramps. I would ideally like a two post

electric ramp but I can't afford one and don't have the space. So looking around on this forum and the interweb I found these

http://www.restorationramps.co.uk/

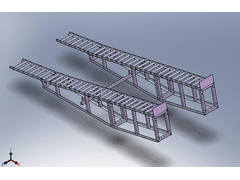

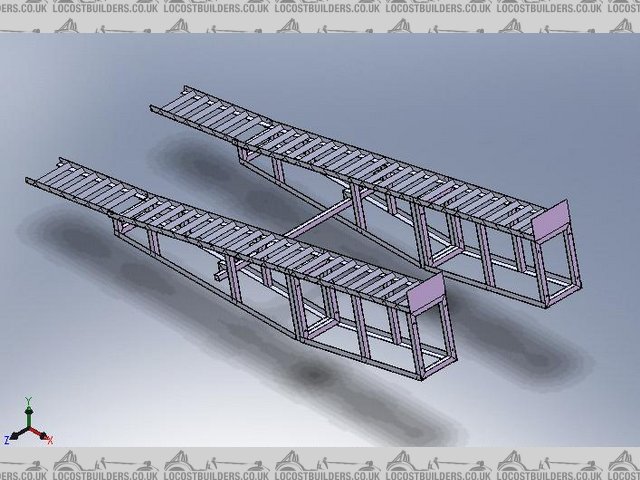

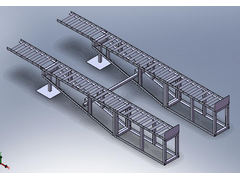

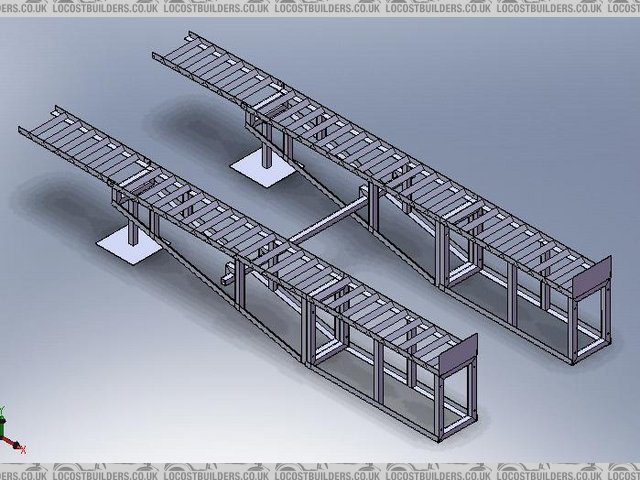

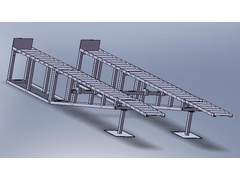

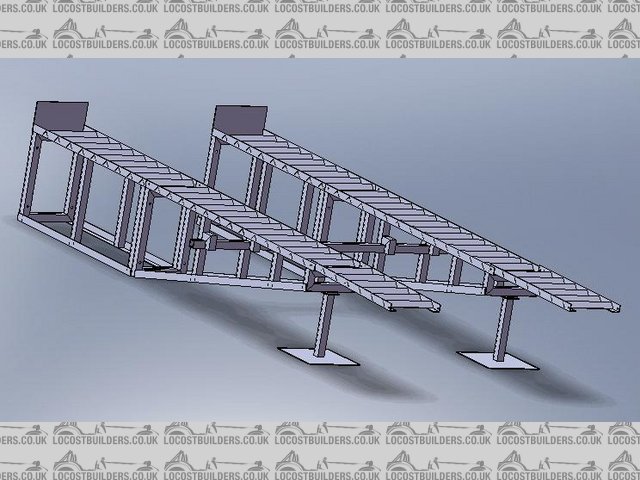

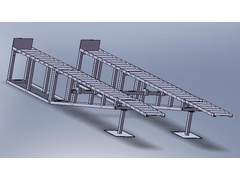

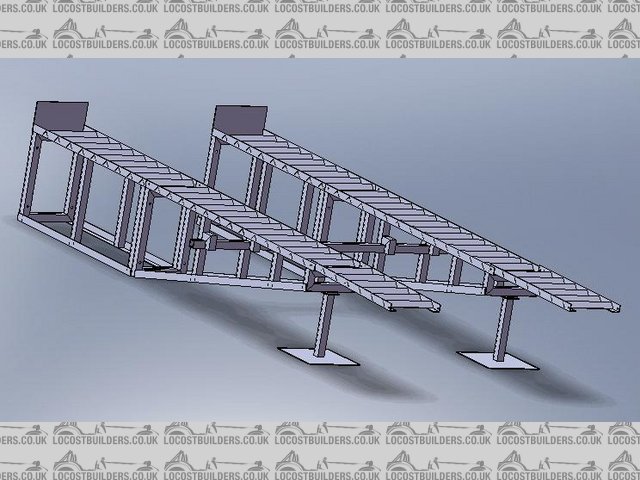

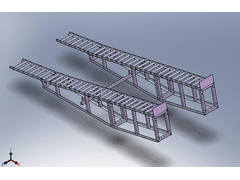

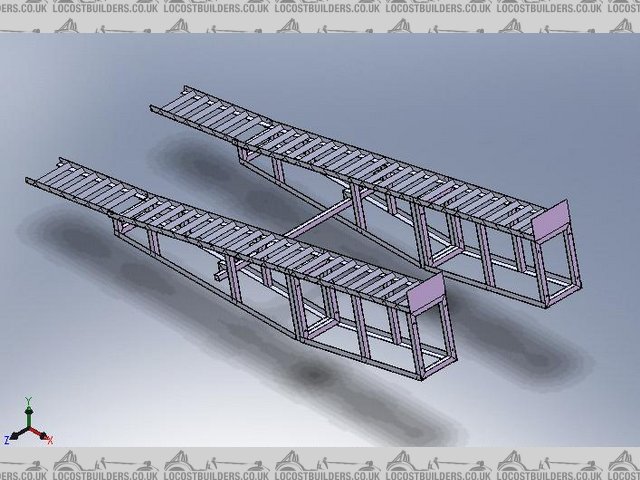

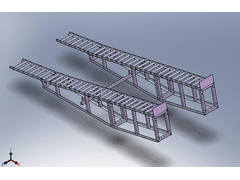

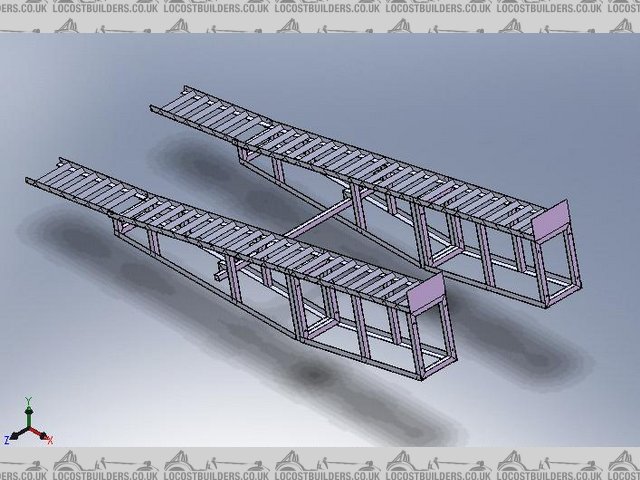

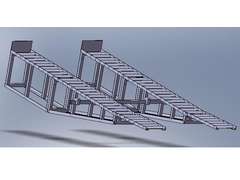

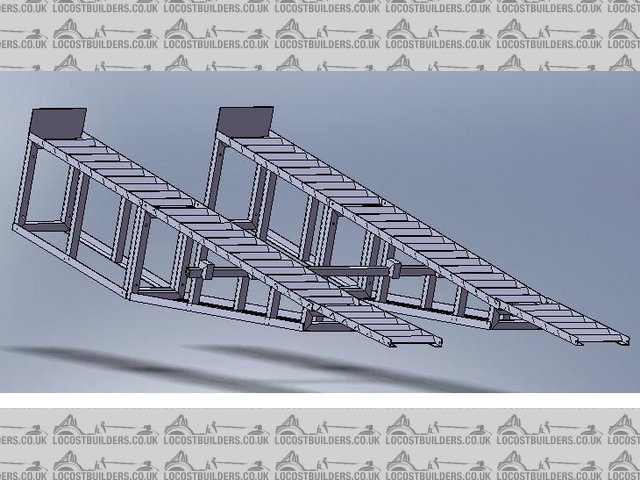

I like to design and the idea but I don't like the price. So I thought I would design my own and get them made. Here are a few pics of what I

have been doing over the last couple of days using Solidworks.

ramps

ramps 2

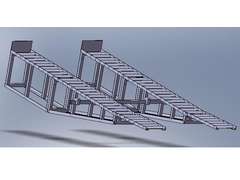

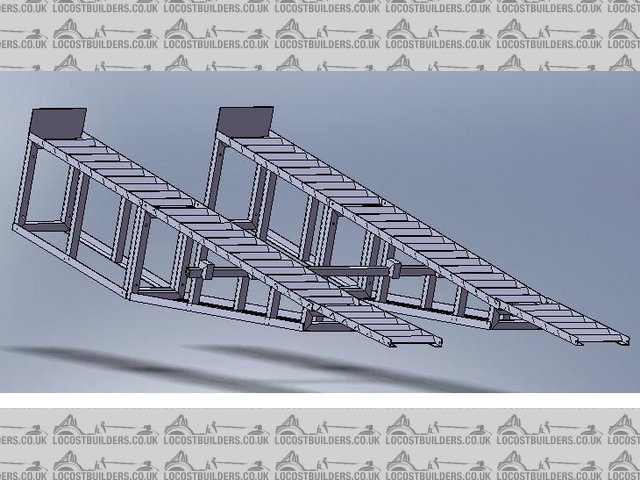

ramps complete setup

ramps complete set up 2

Each ramp is 3500mm long, 400mm wide and 600mm high, excluding the run on ramps. It comes in three parts, front part 1400mm, rear part 2100mm and the

run on ramps 1000mm. The box section and angle pieces are 50mm X 50mm and 5mm thick all of the plate is 5mm thick. It might be a bit of overkill but I

don't fancy having a Legacy falling on me from that hight.

I have tried doing some testing to see how much force the ramp will take before the metal fails but I haven't really used Cosmosworks before so

the results look wrong. Do you guys think 5mm thickness will cope with the weight?

I also designed some rear ramp supports (they are in the last two pics) but these probably wont be used as my axle stands reach the required height

(450mm).

I have done some testing with Cosmosmotion that the centre of gravity is over the rear section. I have also done some weight testing and found that

the ramp will not tip forward with 6000N at 100mm away from the stop plate and 5000N a further 2500mm back, on both sides. This was a rough estimation

of the force that my tin top would put on the ramp.

I thought about how I could jack up the car when it's on the ramp in the upright position, my solution is to lay some 5mm plate on the ramp and

use a car jack to raise it up on the jacking points. Do you think this is a good idea? Any other options?

I want to get these made at some point in the future but I don't have a job at he mo so I cant afford to get them done. What are your opinions on

the design and can you see any improvements that need to be made, all comments welcome.

Regards

Rhod

Edit: I put the pics in, a link from my archive but there not showing up. Anyone know how to do this?

[Edited on 27/1/09 by rodders]

[Edited on 27/1/09 by rodders]

omega0684 - 27/1/09 at 02:51 PM

piccies not showing for me  they do look like a good idea but i have a pit in my garage so im ok

they do look like a good idea but i have a pit in my garage so im ok

[Edited on 27/1/09 by omega0684]

rodders - 27/1/09 at 02:54 PM

Sorry about that. How do you attach pics to a post from your archive?

Regards

Rhod

dinosaurjuice - 27/1/09 at 02:54 PM

heres one:

ramps complete set up 2

rodders - 27/1/09 at 02:55 PM

How did you attach that?

iank - 27/1/09 at 02:57 PM

[pg=37910]

r1_pete - 27/1/09 at 02:57 PM

Just copy and paste the url from your archive, its under the picture when you open it :

ramps

in this case img]http://locostbuilders.co.uk/upload/3ramps.JPG[/img

[ & ] omitted.....

[Edited on 27/1/09 by r1_pete]

[Edited on 27/1/09 by r1_pete]

[Edited on 27/1/09 by r1_pete]

rodders - 27/1/09 at 03:00 PM

Thanks for the help guys. What are your thoughts about the ramps?

Regards

Rhod

Hammerhead - 27/1/09 at 03:05 PM

why not just use 4 of these?

mangogrooveworkshop - 27/1/09 at 03:08 PM

one of the scottish lads was selling a pair like that just a few days ago for not very much money

JeffHs - 27/1/09 at 03:09 PM

They look a great idea. There is a local car dealer who uses very similar ramps to display cars on the forecourt.

The only snag is where you keep them when they're not in use.

mangogrooveworkshop - 27/1/09 at 03:11 PM

http://www.locostbuilders.co.uk/viewthread.php?tid=104079

big ramp

r1_pete - 27/1/09 at 03:13 PM

quote:

Originally posted by rodders

Thanks for the help guys. What are your thoughts about the ramps?

Regards

Rhod

Oh Yes, the thread sort of lost its way a bit didn't it.

They're ok but you probably beed to build jacks in, or how would you take a wheel off, I thought about a pair when I started my MGB, but went for

a rotisserie instead. I bet the first time you drive up them and they see saw, gives the same feeling in the pants as when I 1st rotated the B's

shell, its not normal being able to spin a car over with one had, but if the balance is right......

On its side

[Edited on 27/1/09 by r1_pete]

Delinquent - 27/1/09 at 03:14 PM

why bother with the props at the end? Just make the drive up ramps long / strong enough so that you can pivot the car up then these fold past 90deg to

form the end supports.

marco - 27/1/09 at 03:15 PM

Pm sent Rhod

sorens2 - 27/1/09 at 03:17 PM

Good idea.

I have this solution.

Soren S2

rodders - 27/1/09 at 03:26 PM

I've already got four axle stands but that don't get the cars high enough. I will probably have to do the clutch on my Legacy soon so I need

the car high enough to get the gearbox out with relative ease. I also have a bad knee so getting up and down of the floor is quite painfull, still

hurts after three operations to try and fix it.

Thanks for finding the link to the ramps but for the price them plus the fuel and to get there to pick them up it would probably be cheaper for me to

get them done down in the south when I have the money.

To jack up the car when it's on the ramp I thought about putting some 5mm plate on the ramp and use a scissor jack to raise it up on the jacking

points. Do you think this is a good idea?

Unfortunately I don't like the idea of the ramps pivoting as I drive up them, it would be a brown trouser moment every time I get a car up on

them.

Wish I could afford the two post ramps they would be ideal but no space and no money for them.

Regards

Rhod

[Edited on 27/1/09 by rodders]

Delinquent - 27/1/09 at 03:28 PM

I wouldn't bother with jacks either - just make a long handled lever as per F1 style - as long as the car is close to the pivot point it's

going to require next to no effort to tip it.

rodders - 27/1/09 at 04:33 PM

Sorry I wasn't making myself clear. I would raise the ramps with a trolley jack on the big bar running between the two ramps.

Once it is securely up in the air I was planning to put some 5mm plate steel on the ramps (where the wheels contact the ramp) to lift the car further

up in the air, this would allow me to get the wheels off.

I would use some scissor jacks to do the lifting. Good idea? Do you think the 5mm steel of the whole construction would be able to cope it a 2000Kg

car?

Regards

Rhod

thunderace - 27/1/09 at 04:37 PM

quote:

Originally posted by rodders

Having had enough lying on a cold and often wet floor to do work on my cars so I decided to look into some ramps. I would ideally like a two post

electric ramp but I can't afford one and don't have the space. So looking around on this forum and the interweb I found these

can you make them so that the start bits fold down to the ground then you dont need the stands at the back

http://www.restorationramps.co.uk/

I like to design and the idea but I don't like the price. So I thought I would design my own and get them made. Here are a few pics of what I

have been doing over the last couple of days using Solidworks.

ramps

ramps 2

ramps complete setup

ramps complete set up 2

Each ramp is 3500mm long, 400mm wide and 600mm high, excluding the run on ramps. It comes in three parts, front part 1400mm, rear part 2100mm and the

run on ramps 1000mm. The box section and angle pieces are 50mm X 50mm and 5mm thick all of the plate is 5mm thick. It might be a bit of overkill but I

don't fancy having a Legacy falling on me from that hight.

I have tried doing some testing to see how much force the ramp will take before the metal fails but I haven't really used Cosmosworks before so

the results look wrong. Do you guys think 5mm thickness will cope with the weight?

I also designed some rear ramp supports (they are in the last two pics) but these probably wont be used as my axle stands reach the required height

(450mm).

I have done some testing with Cosmosmotion that the centre of gravity is over the rear section. I have also done some weight testing and found that

the ramp will not tip forward with 6000N at 100mm away from the stop plate and 5000N a further 2500mm back, on both sides. This was a rough estimation

of the force that my tin top would put on the ramp.

I thought about how I could jack up the car when it's on the ramp in the upright position, my solution is to lay some 5mm plate on the ramp and

use a car jack to raise it up on the jacking points. Do you think this is a good idea? Any other options?

I want to get these made at some point in the future but I don't have a job at he mo so I cant afford to get them done. What are your opinions on

the design and can you see any improvements that need to be made, all comments welcome.

Regards

Rhod

Edit: I put the pics in, a link from my archive but there not showing up. Anyone know how to do this?

[Edited on 27/1/09 by rodders]

[Edited on 27/1/09 by rodders]

clairetoo - 27/1/09 at 05:17 PM

The only thing's I can think of are - at 5mm thick , it will weigh a ton , and cost a small fortune to build ! I suspect the weight capacity

would be in the tens of tons..............

rodders - 27/1/09 at 05:26 PM

The design could be modified to allow the run on ramps to be used as the rear supports. It would only require the cutting out of the horizontal

section of the angle iron below where the bolts join the run on ramps and the rear section. This would allow the run on ramps to swing down, removal

of a bit of the angle iron would probably weaken and deform the part of the rear section where the two sections meet.

It's a good idea but I would not feel that comfortable being under the car with only the run on ramps supporting the weight at the back.

I've got two sets of axle stands and it would give me more piece of mind to have them under there than just the run on ramps.

Regards

Rhod

[Edited on 27/1/09 by rodders]

rodders - 27/1/09 at 05:39 PM

According to Solidworks the whole thing would weigh about 500Kg (assuming I put the material values in correctly) but it would come in quiet a few

sections so moving it would be relatively easy.

I'm not sure about the capacity it will take but I rather have it over engineered than under engineered. I don't fancy having a car falling

on me. I will have a look into the cost of getting it made but I don't think it would be more than the cost of one of the restoration ramps.

Regards

Rhod

jollygreengiant - 27/1/09 at 06:06 PM

Looks like the ramps that Geoff Wilking made.

toenee - 27/1/09 at 06:41 PM

I made a set like your design a couple of years ago.

One of the best things i have made, the only problem is my Robin Hood (dont laugh), has narrower wheel centres at the front than at the back.

Dusty - 27/1/09 at 06:42 PM

How about adding some triangulation to those boxes, just like your chassis?

rodders - 27/1/09 at 06:44 PM

That looks good mate, what thickness steel did you use and what's the heaviest car you've had on it?

Regards

Rhod

toenee - 27/1/09 at 06:53 PM

The frame is 30 x 5 angle with 25 x 3 tred bars. I built it to restore my Mk1 MR2, so not so heavy a car, but there was no flex even when jacking on

side from a single point.

Tony

rodders - 27/1/09 at 07:01 PM

Cheers for the reply Tony, From what you have said the 5mm steel I was planning on using should be suitable for my car. Now I just have to find out

how much it will cost and then find the money to do it.

Regards

Rhod

handyandy - 27/1/09 at 07:12 PM

hi, i like the design, simple & effective, the one thought i had was to have a brace at floor level so it won,t stop you working under the car, a

brace between the two structures close to the front end, just to stop them "spreading" as you intially begin to put weight onto the

ramps.

how about making them yourself, i mean doing the welding? sorry if that was already your plan.

andy

rodders - 27/1/09 at 07:32 PM

Good point Andy I didn't think about bracing the two ramps together. I could get some extra cuts of the box section and clamp them to either ramp

at the back and front to stop them spreading.

I haven't welded for a few years now and I would ideally like to do it myself but my welding not up to scratch at the moment. Maybe when I can

afford to do it I will practice and make it myself.

Regards

Rhod

handyandy - 27/1/09 at 07:37 PM

go on! you know you CAN do it, like riding a bike isn,t it???

ok i,ll be honest, i,ve been attending a welding course at locel tech college for few weeks & so i just wanna WELD, lol

good luck & when you do build the system post some pics.

andy

[Edited on 27/1/09 by handyandy]

Canada EH! - 27/1/09 at 07:47 PM

A race shop I used many years ago had a setup like that for doing alignment work, It pivited on a pipe just aft of centre and had two large shocks on

the sides to slow the teeter totter effect, apparently used by British lorries at the time as sway control. worked very well for Mini's and other

Brit cars (they ran three very fast Cooper S race cars 2 1275's and one 970

Schrodinger - 29/1/09 at 12:46 PM

An obvious point but: you will need to ensure that the front of the car does not go beyond the pivot point before the rear wheels are on the ramps.

they do look like a good idea but i have a pit in my garage so im ok

they do look like a good idea but i have a pit in my garage so im ok