rusiq

|

| posted on 5/3/05 at 08:18 PM |

|

|

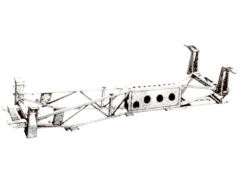

Anyone fancy that idea instead?

Rescued attachment CHASSI_03.jpg

|

|

|

|

|

kb58

|

| posted on 5/3/05 at 10:21 PM |

|

|

Without tortional rigidity numbers, the above chassis is an unknown. *If* the top, bottom, and both sides of the transmission tunnel have riveted

panels, it could be pretty good.

[Edited on 3/5/05 by kb58]

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

cassidym

|

| posted on 5/3/05 at 11:27 PM |

|

|

As a novice, I had a hard time figuring out rusiq's design.

When it clicked I was truly impressed with his innovative thinking - depending on what the experts say I may copy it.

|

|

|

cymtriks

|

| posted on 7/3/05 at 07:26 PM |

|

|

That Cobra chassis

That chassis is a GD cobra and according to their website has 2750 ftlbs per degree of twist. Though it doesn't say if this is with or without

the body fitted.

This is more than twice the book Locost but it has to support about half as much again in weight and a lot more in power. It is very similar in

stiffness to my suggested double Y braced Locost chassis.

The only weakness of the design is the bend in the top chassis tube as it goes round the back of the engine.

The original Elan wasn't far off this design but didn't need a bent tube to get round its much smaller straight four engine. The result

was 4000 ftlbs per degree.

|

|

|

rusiq

|

| posted on 19/3/05 at 04:15 AM |

|

|

The Elan space-frame chassis

Rescued attachment spacef2.gif

|

|

|

rusiq

|

| posted on 19/3/05 at 04:17 AM |

|

|

See these: www.spydercars.co.uk

Rescued attachment CB-3a.jpg

|

|

|

Spyderman

|

| posted on 21/3/05 at 08:46 PM |

|

|

And the Lotus Elan chassis is not a spaceframe chassis. It is a backbone chassis.

Spyderman

|

|

|

MustangSix

|

| posted on 24/3/05 at 03:18 AM |

|

|

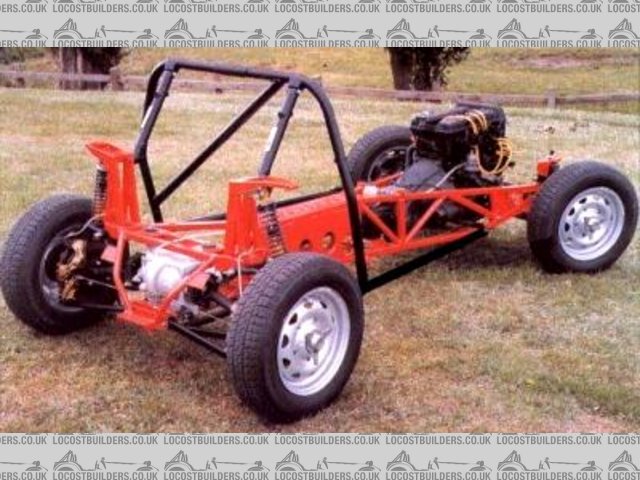

If doors are a requirement, then compromises have to be made. I'd suggest you even look at a ladder style chassis. Though not as rigid as a

space frame, they can be made very light and rigid enough to be a very good street car. It worked for Henry Ford for over 40 years.

Take a look at this hot rod chassis with IFS and a three link and envision an X-brace to stiffen it more and a Locost body over it (with doors). It

gives you a lot of options to add doors, customize bodywork, and install the drivetrain and suspension.

For the naysayers who have never built an American style hot rod with a box steel ladder chassis, this 2x4 steel frame is stronger than it looks! The

one pictured here will easily handle far more horsepower than our delicate little Locust space frame! A 300hp track roadster is a very potent little

car! Move the passenger compartment rearward and extned the hoodline, and the proportions end up very similar to a Locost.

Most roadsters built in this fashion (small block chevy) end up weighing much more than a Locust, about 1600 lbs, but with a lighter drivetrain and

rear end could weigh hundreds less. These are usually somewhat larger than a Locust as well, with a wheelbase of around 100", so it could also

be scaled down for more weight savings.

|

|

|

kb58

|

| posted on 24/3/05 at 03:47 AM |

|

|

quote:

Originally posted by MustangSix

For the naysayers who have never built an American style hot rod with a box steel ladder chassis, this 2x4 steel frame is stronger than it looks!

I guess I qualify then as a naysayer... If a guy floors the gas in this, it'll lift one front tire because of chassis flex. There's only

two tubes under the passenger area and nothing else. What's resisting one bending up/down front-to-back and the other down-up front-to-back....

Yes with extra tubes it could be made better, but this one shown is very likely "complete" as-is.

Having said this, I'd be interested to see what the lb/deg chassis stiffness is. I bet it's way less then a Locost chassis simple because

it has no height to the side rails.

[Edited on 3/24/05 by kb58]

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

MustangSix

|

| posted on 25/3/05 at 02:40 AM |

|

|

Having actually built and driven a couple of similar rods, I can tell you that they definitely do NOT twist that easily. The last one I owned, a 28

Ford roadster, would easily lift the left front wheel, but the right front wheel would accompany it! An exciting ride, to say the least! Again,

300 hp, 1800 lbs. Again,

300 hp, 1800 lbs.

Torsional rigidity is very good on most properly constructed street rods. It's actually very necessary. A stock early Ford chassis is so flexy

that doors can pop open and if you used glass bodywork, you'd be fighting cracks in no time. On my 28 and the 34 before that, the chassis was

stiff enough that those were never issues. The torsional rigidity comes from the fact that the main members are thick wall tubes themselves. Any

chassis twist has to be translated into a twist onto the main rails, and a 2x4 .125" thick tube is hard to twist, I assure you.

I would probably say that the picture above is probably not the best example of stiffness, though. you can do better. That's why my rods

incorporated an X-member on the 34 and a K-member in the 28 to reduce chassis flex. Is it as rigid as a space frame? Likely not, but unless you

intend to go road racing, a box tube ladder is more than stiff enough (and far stiffer than Henry's originals) for a street car. I won't

argue that for some purposes, the space frame is superior.

A properly constructed space frame would be lighter and stiffer. But as I said, if doors are needed, compromises must be made. I think in that case

I would prefer a tried and true ladder design to a highly modified Locust book-chassis space frame. Not that I'd ever convince any of you

fellow Locost disciples.

|

|

|

iwbunting

|

| posted on 25/3/05 at 10:36 PM |

|

|

Doors

Read all the posts.

Has anybody considered gull wing doors.

I have come up with 2 ideas for these that would be quite feasable.

1:solid framed or formed lexan sheet.

2:Fabric (leatherette) roll up.

Both supported by an overhead central tube running from the top of the windscreen surround to the top of the rollbar tube.

Any comments ???

|

|

|

kb58

|

| posted on 26/3/05 at 02:27 AM |

|

|

They should work fine, though I don't see how they would allow for a stiffer chassis. The doors will intrude into the chassis as much as the

space needed to squeeze through them, regardless of where the hinges are.

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

turbo time

|

| posted on 26/3/05 at 06:41 AM |

|

|

I think the formed lexan doors wouldn't be a bad idea. Although, if you were adding doors which you really wanted to function and make the car

more liveable in incelment weather, you might as well just make some real ones from steel, or alum.

It wouldn't be a huge deal to put a dip of a few (or several? ) inches in the outer sill in order to make room for a hard door.

You would lose some stiffness, sure, but a tremendous amount? A mushier chassis may help forgive poor shock/spring/anti-roll tuning and keep all 4

tires on the road, I'm not encouraging this, just throwing it out there. just ask Carroll Shelby, the AC cobra chassis was so floppy that this

was the exact case.

[Edited on 26/3/05 by turbo time]

|

|

|

stevebubs

|

| posted on 28/3/05 at 10:11 PM |

|

|

There's always following the JP's (Sylva) thinking with the Stylus

|

|

|

kb58

|

| posted on 29/3/05 at 04:05 AM |

|

|

Good heavens that's a monster; I'd put on much larger rear tires. As it is I'd guess you'd have wheel spin "on

demand" all the way up to around 100mph....

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

cymtriks

|

| posted on 29/3/05 at 08:32 PM |

|

|

Ladder frames etc...

quote:

Originally posted by MustangSix

Is it as rigid as a space frame? Likely not, but unless you intend to go road racing, a box tube ladder is more than stiff enough (and far stiffer

than Henry's originals) for a street car. I won't argue that for some purposes, the space frame is superior.

A properly constructed space frame would be lighter and stiffer. But as I said, if doors are needed, compromises must be made. I think in that case

I would prefer a tried and true ladder design to a highly modified Locust book-chassis space frame. Not that I'd ever convince any of you

fellow Locost disciples.

I've done the math on the computers at Rolls Royce.

Most ladder frames are stiffer than most spaceframes.

And with the appropriate choice of tube size and wall thickness they can be lighter than most spaceframes as well.

A well designed X braced ladder frame will be stiffer, lighter, cheaper, easier to weld, will allow freer exhaust routes, be easier to get in and out

of, allow easier access for maintainance and allow greater choice of engines compared to the majority of spaceframes.

A spaceframe is only better, by which I mean stiffer and lighter, if it is properly triangulated and most of them aren't. This is what really

makes the difference.

I know a colleague who has built a car very similar in concept to kb58s kimini. It used a ladder frame with a mid mounted Peugeot 205 drivetrain and a

mini shell. It works just fine apparently.

|

|

|

kb58

|

| posted on 29/3/05 at 08:50 PM |

|

|

Thanks, that's good to know. I always assumed a basically two-dimensional ladder frame could never be stiffer in torsion than a

three-dimensional space-frame chassis. I guess it's like you said, if there isn't proper triangulation, the fact that it's 3D

doesn't help.

I never measured my chassis for torsional stiffness... and probably won't at this point. No point in disappointing myself like I did when I

weighed it!

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

kreb

|

| posted on 29/3/05 at 09:57 PM |

|

|

Does anyone have more pictures of the Stylus? That's an interesting chasis. I did a web search and only came up with body pics.

https://www.supercars.net/blog/wp-content/uploads/2016/04/1966_FiatAbarth_1000SP1.jpg

|

|

|

goat

|

| posted on 28/3/06 at 01:29 PM |

|

|

about the door concept -

has anyone thought that if you want full doors and thus lower the sill that you could put a full roll cage over the top of the windscreen thus

completing the normally incomplete box, which thereby renders the sill pretty well useless anyway. The cage would have to fit in behind the windscreen

and could therefore attach directly to the chassis.

|

|

|

DorsetStrider

|

| posted on 31/3/06 at 11:06 AM |

|

|

quote:

Originally posted by Jermyn

I figured building a mix of a ladder frame and space frame will allow for the open door section. (if i decided to do the doors)

Developing a mix of the two applications in theory and testing them with models is not beyond my skill level. However, this method would not be

reliably accurate.

Realistically, they would need to be built or engineered through some sort of design/test program which I have no access to or knowledge about. Plus,

I'm not trying to spend 10 years designing a chassis just so I can have doors.

On the other hand, plenty of autos have been built on unreliable engineering ideas that have been successful. Space frame and ladder frames both have

benefits. Why not make them both work in a hybrid sort of chassis. Who's building a hybrid sort like this now?

Correct me if i'm wrong but I'm 99% sure that most current ferrarri's are built in this manor. I KNOW the enzo is part ladder part

space frame.

Who the f**K tightened this up!

|

|

|

architect

|

| posted on 11/5/11 at 11:38 PM |

|

|

quote:

Originally posted by goat

about the door concept -

has anyone thought that if you want full doors and thus lower the sill that you could put a full roll cage over the top of the windscreen thus

completing the normally incomplete box, which thereby renders the sill pretty well useless anyway. The cage would have to fit in behind the windscreen

and could therefore attach directly to the chassis.

Just wanted to revive this thread, specifically the suggestion above and get the experts' take on this. TIA.

|

|

|

ettore bugatti

|

| posted on 13/5/11 at 06:41 PM |

|

|

I think there is a lot to say for a ladderframe from scratch, compared to adapting a Locost design.

Personally I would think that for a 'european' car you could use two rails of 3x2" and around 5 or 6 crossmembers in between. Off

course the stiffness would increase by a properly design firewall (with integrated A-pillar)

Not unsimiliar what the Italians did in the fifties and sixties.

http://www.gilcodesign.com/doc/GILCOdesignAUTO.htm

This budget hotrod build use the same principles. Page 4 and further.

http://www.hotrodders.com/forum/journal.php?action=view&journalid=17166&page=4&perpage=5&reverse=1

|

|

|

hughpinder

|

| posted on 16/5/11 at 08:53 AM |

|

|

4 years ago (eek) when I started my design I had a copy of a document comparing the strengths of various chassis designs vs weight. I'll have to

try to dig it out. But basically it comared a locost chassis, with an aus adapted design to a basic ladder and an X braced ladder. I think the ladder

was 60*40*3. and about 10% heavier than a well designed' space frame of the same strength. If I can find it again I'll post up a link. I

do remember thinking that you'd have to add some more weight to the space frame though, as the locost ladder effectively supports the

body/steering wheel, give somewher to mount header tanks etc without any more weight, wheras you'd need to add them to the ladder.

Regards

Hugh

|

|

|