Doug68

|

| posted on 9/3/10 at 01:26 PM |

|

|

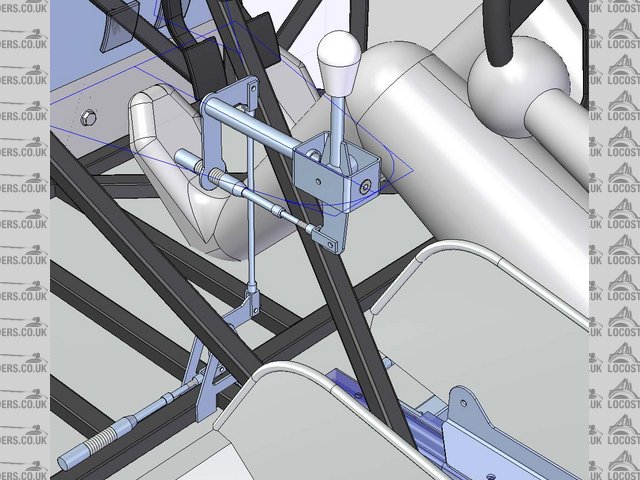

My shifter design.

Hi All,

I've come up with this for a shifter design.

Fore - Aft

The fore - aft movement is a direct push pull onto the cable. The outer of the cable goes forward and loops around to the rear. The outer also moves

with the left - right movment of the shifter.

Left - right

Left - right goes down through a linkage to the cable mounted on the floor. I would have made this a direct action as well, but there was not enough

room to make the turn in between the shifter and the floor.

The cables I intended to be 2" movement 1/4" items from MidwestControl.com

Anyway does the idea look lunatic or not?

I've not shown the support bracketry around the shifter, but you can imagine that.

Are 1/4" cables sufficient in size? All the larger ones I've seen have 3" or more movement which is excessive, the 1/4" versions

can have 2" of movement.

Rescued attachment Shifter.jpg

Doug. 1TG

Sports Car Builders WA

|

|

|

|

|

Alan B

|

| posted on 9/3/10 at 02:29 PM |

|

|

Doug,

Looks good.

My only questions would be be could reverse the whole thing to make your fore aft cable go backwards?..I know it may affect other things of course.

Also, why does the L/R cable go off sideways instead of backwards between the seats?...just questions and certainly not criticism.

I think 1/4" should be Ok....it's all about the push really......in tension 1/4" is a huge cable.....how does that compare with

standard cables?

Is that solidworks?....the driver looks familiar...

[Edited on 9/3/10 by Alan B]

|

|

|

MikeR

|

| posted on 9/3/10 at 02:39 PM |

|

|

variation on alans comment - instead of having the push rod going down for left / right that pivots on a crank - why not attach the cable where the

push rod attaches to the mechanism at the top? Means a bend in your cable - but you'd have that anyway.

Less manufacturing / everything is packaged closer together.

|

|

|

rachaeljf

|

| posted on 9/3/10 at 03:02 PM |

|

|

Hi Doug,

How about pinching and adapting an OEM design? This is an Alfa Romeo gearstick, flipped upside down and back to front for a mid-engined design (Alfa

V6 into Fiat X1/9).

The cable movement describes how much movement is available with the given cable size, you don't have to use it all! There's no reason why

you can't use a larger cable and just use say only 1" of the 3" available.

Cheers R

|

|

|

Doug68

|

| posted on 9/3/10 at 03:18 PM |

|

|

Yeah the cables need to go down the LHS of the car to get into the engine compartment.

I've set the shifter high (cause I can) so its closer to the steering wheel than on the floor, where frankly theres no room anyway.

Originally the left right cable had no linkage but the bend radius for these cables is 8" and with the hard components at the ends of the cables

it wasn't going to fit.

this is why I'm looking for cables with 2" throw its still more than I need but the "hard ends" to the cables is ~1/3

shorter.

I use Solid Edge but that driver gets about ;o)

On the manufacturing, I've had a quote for ~A$20 to get all the plates laser cut that are required for the design.

[Edited on 9/3/10 by Doug68]

Doug. 1TG

Sports Car Builders WA

|

|

|

Alan B

|

| posted on 9/3/10 at 03:36 PM |

|

|

He must be the Stig of CAD I guess...

Good answers by the way....looks good.

|

|

|

02GF74

|

| posted on 9/3/10 at 05:35 PM |

|

|

looking at where the pedals are, the "shifter" I presume is for bike engine, would be pushed/pulled only?

i.e. in drawing moved left-right.

how can it move the linkage which requires movement at 90 degrees to what the gear knobbed thing would supply?

confused......

|

|

|

Doug68

|

| posted on 9/3/10 at 11:43 PM |

|

|

This is for a normal H psttern 5 speed, not a BEC.

Doug. 1TG

Sports Car Builders WA

|

|

|

cheapracer

|

| posted on 21/3/10 at 04:07 PM |

|

|

Looks like you have decided your own route Doug but i hope it doesn't scare others off as they see so many things that "need to be

done" that actually don't.

Cable shifters are a dime a dozen and can be found in numerous sizes in a lot of FWD cars and especially small Asian vans such as Suzuki and Daihatsu.

They are simple, cheap, easy to install in many orientations and if any work or extension needs to be done then a very simple quadrant setup that can

be used to reverse either cable's movement or/and lengthen/shorten the throw.

When I get my camera back from the repair shop I'll take a picture of a simple one at work to explain it if anyone wants to see what I am on

about.

|

|

|

cheapracer

|

| posted on 21/3/10 at 04:08 PM |

|

|

quote:

Originally posted by Doug68

This is for a normal H psttern 5 speed, not a BEC.

And the same type of cable shifter with just one cable of course can also be used for a BEC too.

It's coming....

|

|

|