peter_m7uk

|

| posted on 6/11/10 at 04:29 PM |

|

|

Bonnet bulge in fibreglass

Hi,

My EFi Pinto is too tall to fit under the bonnet and I didn't want to go for a modded manifold, so I cut a hole in the bonnet, but now looking

for ways to fit a bulge. I reckon a fibreglass job in red gelcoat would look great, but I have no previous experience in this and it's one of

the few jobs that I'm happy to let someone else do. In fact, it's probably making the mould that's the tricky/time-consuming bit,

as I don't think producing the piece out of the mould is *that* hard! Anyone know of a bespoke fibreglass part maker?? If they were near

Hove all the better, but I could always send a diagram to show exactly what I want.

Cheers,

Pete

|

|

|

|

|

daniel mason

|

| posted on 6/11/10 at 05:22 PM |

|

|

you can buy them pre made so no moulds would be needed! i think dax sell them and someone on here makes them (but they are large. alternatively

carbonmods sell them in c/f but not the cheapest!

|

|

|

peter_m7uk

|

| posted on 6/11/10 at 06:03 PM |

|

|

Hi Daniel,

I meant to say that I'd already looked at pre-made bulges, but couldn't find anything suitable. Part of the problem is that the Pinto

EFi manifold slopes up toward the rear of the engine bay and sticks out several centimetres, so the usual kind of scoop bulge wouldn't work.

I've seen the carbonmods one and don't think that would work either, although could try fitting it backwards! Anyone got a picture of

the Dax one, can't seem to find that. I still think a bespoke piece would be the ultimate - Don't mind shelling out if it looks really

good!

Pete

|

|

|

Triton

|

| posted on 6/11/10 at 06:06 PM |

|

|

Have a butchers in my archive as there are pics in there of bonnet bump things...My daughter has got the mould so if it's something you feel

will work let me know.

Cheers,

Mark

My Daughter has taken over production of the damn fine Triton race seats and her contact email is emmatrs@live.co.uk.

www.tritonraceseats.com

www.hairyhedgehog.com

|

|

|

daniel mason

|

| posted on 6/11/10 at 07:06 PM |

|

|

search user name chris taylor under his thread new bonnet scoop! im sure that will fit and i think it looks good

|

|

|

stevegough

|

| posted on 6/11/10 at 08:20 PM |

|

|

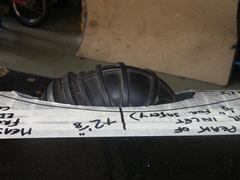

I had the same problem - I cheated and gave it to a fibreglasser friend who also cheated - he sourced a scooter mudguard, cut it to shape and bonded

it all round with fibreglass - result - see below.

Hope this helps?

Description

Luego Locost C20XE.

Build start: October 6th 2008.

IVA passed Jan 28th 2011.

First drive Feb 10th 2011.

First show: Stoneleigh 1st/2nd May 2011.

'Used up' first engine may 3rd 2011!

Back on the road with 2nd engine may 24th

First PASA mad drive 26/7/11

Sold to Mike in Methyr Tydvil 19/03/14

|

|

|

peter_m7uk

|

| posted on 6/11/10 at 08:28 PM |

|

|

quote:

Originally posted by Triton

Have a butchers in my archive as there are pics in there of bonnet bump things...My daughter has got the mould so if it's something you feel

will work let me know.

Cheers,

Mark

Hi Mark,

They look smart, particularly the teardrop one, although I fear it would be too small (must get a pic of the problem for you). Don't suppose

you have any dimensions handy for them?

Thanks,

Pete

|

|

|

peter_m7uk

|

| posted on 6/11/10 at 08:36 PM |

|

|

quote:

Originally posted by daniel mason

search user name chris taylor under his thread new bonnet scoop! im sure that will fit and i think it looks good

That is a biggie!!! I'm sure it would fit, although for my taste it looks a bit over the top. I found pics on the Dax website in the end,

although I can't see a price. Just wondering how they attach it now, as I can't see a lip, unless it's on the inside.

Cheers

|

|

|

peter_m7uk

|

| posted on 6/11/10 at 08:39 PM |

|

|

quote:

Originally posted by stevegough

I had the same problem - I cheated and gave it to a fibreglasser friend who also cheated - he sourced a scooter mudguard, cut it to shape and bonded

it all round with fibreglass - result - see below.

Hope this helps?

Description

Hi Steve,

That looks great! Unfortunately, my protrusion is longer and wider than that (oo-er), so don't think I could get away with a copy of that

solution. I keep waiting for inspiration on something of the right size and shape, but it never comes! I'll get a pic of it, so that you can

see the trickiness of the problem.

Pete

|

|

|

stevegough

|

| posted on 6/11/10 at 08:53 PM |

|

|

Sorry, didn't realise you had a big one. mine was just to cover my little pipe

Description

Luego Locost C20XE.

Build start: October 6th 2008.

IVA passed Jan 28th 2011.

First drive Feb 10th 2011.

First show: Stoneleigh 1st/2nd May 2011.

'Used up' first engine may 3rd 2011!

Back on the road with 2nd engine may 24th

First PASA mad drive 26/7/11

Sold to Mike in Methyr Tydvil 19/03/14

|

|

|

2cv

|

| posted on 7/11/10 at 10:39 AM |

|

|

Why not try this approach?

http://www.locostbuilders.co.uk/viewthread.php?tid=143519

You can make it any shape you want and glass it onto your bonnet just as easily as if it were fibreglass.

[Edited on 7/11/10 by 2cv]

|

|

|

peter_m7uk

|

| posted on 7/11/10 at 06:43 PM |

|

|

quote:

Originally posted by 2cv

Why not try this approach?

http://www.locostbuilders.co.uk/viewthread.php?tid=143519

You can make it any shape you want and glass it onto your bonnet just as easily as if it were fibreglass.

[Edited on 7/11/10 by 2cv]

Hiya 2CV (sorry, can't find your name!), I must say that does look really nice!!! Pushing the shape out was something that had occurred to

me, but I assumed that aluminium would simply crack and tear, so I thought nothing further of it.

I have NO experience of this kind of metal-working, however. I've never heard of a bossing mallet and "planish with a dolly and

slapper" sounds like something that would happen in a nightclub at 3am  But I'm game But I'm game

I see you can get 1.5mm 1050A ali on 1.5mm Aluminium Sheet 1050A: 1000mm x 1000mm on eBay (end time 29-Nov-10 18:54:32 GMT) , but don't know how important the grade is?? I have sheets of ali lying about from my kit, but no idea what they are. I'm a bit

worried by RK's comment that he thought it was just too hard to do... Although if you say it's only 3hrs work, then could give it a

try.

, but don't know how important the grade is?? I have sheets of ali lying about from my kit, but no idea what they are. I'm a bit

worried by RK's comment that he thought it was just too hard to do... Although if you say it's only 3hrs work, then could give it a

try.

Annealing also sounds like a black art, although there's a decent article

here. At £25 a sheet, could get quite expensive if it took several goes!

I am interested though  If you could give more detail to an absolute beginner, that would be great! If you could give more detail to an absolute beginner, that would be great!

Pete

|

|

|

peter_m7uk

|

| posted on 7/11/10 at 07:01 PM |

|

|

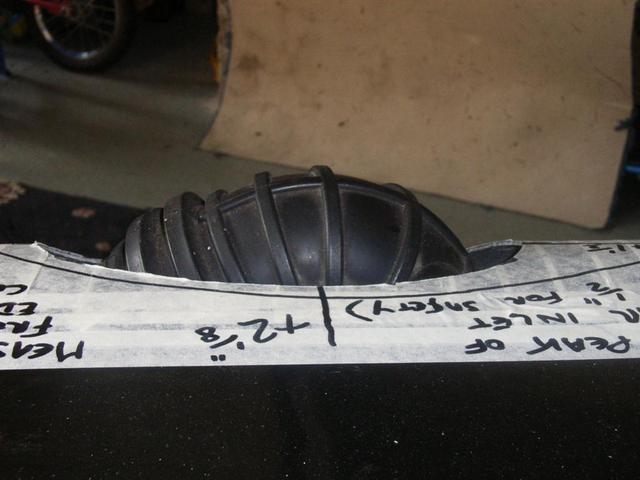

Ok, I said I'd get some pics, so took these ones this afternoon. For info, the bonnet hole is 370mm long and 200mm wide at the maximum. The

manifold protrudes 45mm above the bonnet at the highest point. As you can see, it's quite off-centre and the bonnet is starting its curve down

on the right-hand edge, to make things trickier. This may be a problem for the ali-bashing idea, as you have to mount the piece in flat sheets of

wood. Might be able to work with this problem, though.

|

|

|

peter_m7uk

|

| posted on 7/11/10 at 07:05 PM |

|

|

Hmmm, where are the pics? What did I do wrong?! I pressed the button for images and inserted the URL, but nothing....

|

|

|

jacko

|

| posted on 7/11/10 at 07:30 PM |

|

|

Photos to big i think

Jacko

Bonnet hole 2

[Edited on 7/11/10 by jacko]

|

|

|

2cv

|

| posted on 7/11/10 at 08:09 PM |

|

|

Hi Pete, sorry my name is John and thank you for your reply.

If you do decide to have a go check to see how easy your scrap aluminium is to bend. If it's springy, it is probably a tough alloy and working

it would be difficult. I would suggest you try to find 1050A pure aluminium either 1.2 or 1.5mm thick sheet. You may find your local non-ferrous stock

holder will supply small pieces. Failing that, if you let me have cut out in card of the shape of the bulge and also the profile ie max height and any

taper, I'll see if I can make one for you.

atb

John

ps I think the slope on the outside can be accommodated by the mounting flange which being soft can be shaped to fit.

[Edited on 7/11/10 by 2cv]

|

|

|

peter_m7uk

|

| posted on 7/11/10 at 09:45 PM |

|

|

Hi Jacko, so it's one pic at a time, then? I'll give it a go.

John, thanks for your reply. I don't think I've got a tough alloy, found it fairly easy to bend in the past. Does the 1050 stuff have

the most "workable" properties, I take it? I'm not sure that I'd want to impose on you, not without a handsome sum of money

changing hands, of course! Also, I'm wondering how to attach and finish the piece neatly. My intention was to have an unpainted ali bonnet

with a red fibreglass bulge, but if I went this route would I be forced to filler and paint to make it look good? Wasn't sure if I could put

the lip on the underside and stick some edging round the join, then keep it all ali.

Thanks again,

Peter

PS Still didn't get the pics to work, but they're in my photo archive, so easy to access. Cheers.

[Edited on 7/11/10 by peter_m7uk]

|

|

|

2cv

|

| posted on 8/11/10 at 07:56 AM |

|

|

It's just my opinion, if you have an aluminium bonnet particularly a polished one it is good to have aluminium fittings rather than fibreglass.

The bulge can be polished as well and it all looks like one part rather than an add-on. The bulge can be riveted on as the extraction flutes in this

picture.

[img]

Description

[/img]

If you do decide to have a go you'll be surprised how easily the aluminium forms but I'd recommend that you use either a wooden mallet with

a rounded head or a piece of hardwood shaped to the kind of radius you want and hit that with a Thor hammer or the like. You actually don't have

to put an awful lot of shape into it to give the clearance you need.

If all else fails, I'll be pleased to make one for you for the cost of the postage.

atb

John

|

|

|

dickie b

|

| posted on 8/11/10 at 09:14 PM |

|

|

try dropping Andy Westgate a line - he makes all sorts of stuff in GRP / plastics. He is currently doing my fury bonnet bulge (among other mods) and

the results so far have been superb

www.westgatecomposites.com

I think he may have some 'off the shelf' moulding that may work for you - well worth a call.

|

|

|