Browser

|

| posted on 28/8/11 at 03:58 AM |

|

|

Lifting beam in garage

Fellow members, I'm looking at fitting a lifting beam in my garage to make engine hoiking easier. I have access to an engine crane from my work

but it's a 1-tonne capacity model and weighs a tonne itself (besides being a pig to move) so isn't as convenient as it could be.

I thought a beam in the garage would do but have thus far struggled to fing any images of installations. I don't really want to knock bricks out

of the walls to socket anything in so was hoping to use spreader plates and anchor bolts.

Does anyone have any tips or pics of their own installation?

|

|

|

|

|

daviep

|

| posted on 28/8/11 at 06:45 AM |

|

|

What are your garage walls made of and what span would the beam be?

Davie

“A truly great library contains something in it to offend everyone.”

|

|

|

cliftyhanger

|

| posted on 28/8/11 at 07:00 AM |

|

|

I have used these brackets in my garage in the past

http://www.wickes.co.uk/joist-hanger/invt/246014/

it required some mortar to be removed/replaced and also I used a 1m length of 75mm angle iron vertically underneath, with a few 12mm holes and anchors

through.

A 9" wood joist was a good tight fit, lifted hefty Triumph six cylinder engines/boxes in and out quite a few times.

It appealed to have some metal going into the wall, if you are handy you could easily make up a better version, maybe a couple of 500mm long bits of

angle iron let into the mortar gaps a few brick courses apart, a bit of plate welded to them both and anchored into the wall, and brackets welded onto

that?

But in all reality, the simplest/best thing is to knock a few bricks out and rest an RSJ on a padstone.

|

|

|

HowardB

|

| posted on 28/8/11 at 07:13 AM |

|

|

If you don't want to knock bricks out, may I humbly suggest that you use props, 4"x4" timber fixed to the wall, and the beam resting

on top,..

works for me,..

Howard

Fisher Fury was 2000 Zetec - now a 1600 (it Lives again  and goes zoom) and goes zoom)

|

|

|

scootz

|

| posted on 28/8/11 at 08:31 AM |

|

|

I had an RSJ put into my garage when it was being built... I'll get you some pics later today.

The plan was to put a push travel trolley on it...

It's Evolution Baby!

|

|

|

40inches

|

| posted on 28/8/11 at 03:35 PM |

|

|

quote:

Originally posted by scootz

I had an RSJ put into my garage when it was being built... I'll get you some pics later today.

The plan was to put a push travel trolley on it...

Yep! RSJ plus trolley works really well for me.

Description

|

|

|

coozer

|

| posted on 28/8/11 at 03:55 PM |

|

|

1972 V8 Jago

1980 Z750

|

|

|

Browser

|

| posted on 28/8/11 at 10:49 PM |

|

|

quote:

Originally posted by daviep

What are your garage walls made of and what span would the beam be?

Davie

Breeze block and approx 2.4m (ish).

|

|

|

rusty nuts

|

| posted on 29/8/11 at 07:58 AM |

|

|

When I built a garage at a former home I used concrete blocks and where I wanted the RSJ to sit I built a double

thickness pillar with 3 rows of engineering bricks at the top to take the weight. I wouldn't want to take any great weight on breeze blocks.

|

|

|

Peteff

|

| posted on 29/8/11 at 09:34 AM |

|

|

quote:

Originally posted by Browser

[Breeze block and approx 2.4m (ish).

Are they breeze or concrete blocks, can you knock a nail into them? True breeze blocks are soft but concrete blocks are harder and heavier.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

907

|

| posted on 29/8/11 at 10:17 AM |

|

|

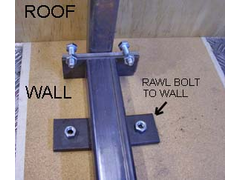

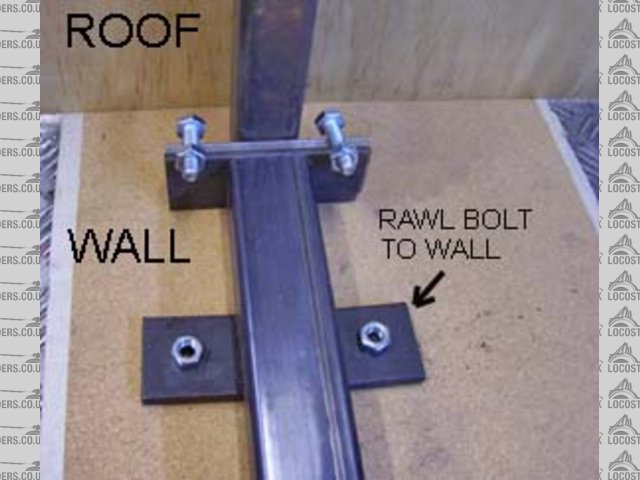

To avoid the wall taking all the weight I would rawl bolt a couple of vertical box sections

to the floor and wall.

A cross member could then be bolted to the top of them, with some sort of sliding hook.

As I'm crap at drawing I've balanced bits of scrap together and photographed them to give an idea.

Disclaimer.

I haven't done calcs for this but I would guess that 50x50x3 up the walls and 80x40x5 (on edge)

for the cross beam would take the weight of an engine. Perhaps some one can work it out.

Cheers,

Paul G

Description

Description

Description

|

|

|

Fred W B

|

| posted on 29/8/11 at 05:16 PM |

|

|

I would support the suggestions for props.

As for cross beam size, depends on the span, and if the ends are simply supported or built in. Best to design for deflection, if I can remember the

formula and dig the "I" tables out.

Cheers

Fred W B

[Edited on 29/8/11 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

pajsh

|

| posted on 29/8/11 at 06:52 PM |

|

|

Steel beam cost £45 sized by my structural engineer at work and rated at 1t. I think it's a 178 x 89 RSC or similar metric eqiv.

Span is around 2400 and ends are cleated to the brickwork but it bears on two handy brick nibs that provide stiffness to the garage wall. Some hefty

timber bolted to the blockwork would do but I would use resin anchors not expanding ones just to be safe.

Can dig out the full spec and calcs if you like.

[img] [/img] [/img]

Guess I better add the beam came bear steel so I had to grind off the scale, red oxide and spray it. Paints cost me £25 too but a can of hammerite

would probably do.

[Edited on 29/8/11 by pajsh]

I used to be apathetic but now I just don't care.

|

|

|

Fred W B

|

| posted on 29/8/11 at 07:15 PM |

|

|

The above post has reminded me that I did design a beam a while ago for my garage:

Max center point load 500 kg

Span 5500 mm

Beam simply supported

Minimum size beam required IPE 140 (I beam 140 high, 73 wide, 12.9 kg/m)

Cheers

Fred W B

[Edited on 29/8/11 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Browser

|

| posted on 29/8/11 at 10:26 PM |

|

|

Thanks for the feedback gents, very useful.

Definitely breeze blocks, PITA to drill into straight without using a wooden block on the surface as a guide, and can have nails knocked into them.

I had thought along the 'supported by more steel' lines so might pursue that. If you can dig out the aforementioned calcs pajsh

that'd be right nice of you. I'll have to go and see how much the steel will cost me, might be easier just to get on and modify my trailer

so it's got a drop back, fit it with ramps and transport the engine crane that way

|

|

|