robocog

|

| posted on 6/5/12 at 07:48 PM |

|

|

Metal garage roof apex issues

Hey - not posted in a while

Garage is now up and it has a roof

...see my vids of it going up:-)

Garage build

part 1

part 2

part 3

Gone with metal sheet roofing in the end

I'm REALLY struggling on getting the apex on however and need suggestions

The sheet metal is a lot thinner and flexier than I had thought it would be so I don't feel I can trust walking on it

I did lean quite hard on one edge reaching across to fix one sheet down and it bent like it was made out of paper

(luckily managed to de-crimp it)

I only have good access to 2 sides - the other 2 edges are pretty tight up against flimsy fencing

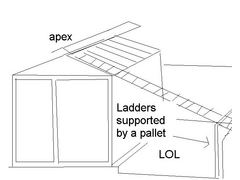

Tried leaning a laddder across the roof angle (see dodgy diagram) but as you can see its not that simple

Had to use a pallet to support the other end and butted it up against another very flimsy fence

[img]

Description

[/img]

Roof is plastic coated and slippery as a slippy thing...which doesnt help

I did put /some/weight on it in the above dodgy lash up and am convinced its going to buckle the metal roof if I put my body weight on it

There must be a simple and effective method (I don't have a cat to train in the use of a drill...besides they dont have thumbs)

Answers on the back of a postcard please

Regards

Rob

Edited to add

The apex is held on by self drilling self tapping screws through the upper part of each panels box section

[Edited on 6/5/12 by robocog]

|

|

|

|

|

MikeR

|

| posted on 6/5/12 at 07:53 PM |

|

|

could you not take off all but the first roof sheet on you lawn side. Then reach up from inside the garage and fit the first bit of capping. Add the

second bit of roof, move down and secure the capping. Repeat untill complete.

|

|

|

zilspeed

|

| posted on 6/5/12 at 08:31 PM |

|

|

You can certainly fix the ends without worrying about leaning on the mid section.

You'll get a good bit from the front and then the back.

I might be tempted to put a ridge in there to strengthen that zone and give something extra to fix to.

[Edited on 6/5/12 by zilspeed]

|

|

|

Bare

|

| posted on 6/5/12 at 08:34 PM |

|

|

Something seems Odd.

Usually the Metal is seamed vertically, so Apex fitting is a non issue. Just stand inside the garage and apply the panels ..And.. the Apex ..

sequentially

What? did you Buy??

Hopefully you installed a full waterproof Membrane .. Under.. the tin bits??

Metal roofs Sweat heavily. Yup.. indoor rain.

Best get one of those hats with an umbrella on top, if not :-).

|

|

|

Bare

|

| posted on 6/5/12 at 08:34 PM |

|

|

oops. sorry.

[Edited on 6/5/12 by Bare]

|

|

|

gazza285

|

| posted on 6/5/12 at 08:40 PM |

|

|

Roof sheets should be fine to walk on, I'm guessing that you don't have enough purlins?

DO NOT PUT ON KNOB OR BOLLOCKS!

|

|

|

robocog

|

| posted on 6/5/12 at 08:51 PM |

|

|

Good suggestion - but the apex covers the top rows of fixing screws for the sheets

and the apex is in 2 lengths each 3 m long

so the apex - at the moment - has to be the last to go on

There are only 2 angle iron supports per side running the length of the garage - and the apex is wider than the top pair so I had no choice where to

fix the sheets to so your suggestion could work if I cut the apex into smaller pieces and overlap them

Good call :-)

Will do that if nothing else turns up

Didn't see the other replies due to taking so long to compose the first reply..LOL

Zil - managed to get one apex piece on - as you say reaching across

I managed to get screws into the first meter by leaning across - now worried if we get high winds its going to write that piece off if it gets bent

Bare- its all screwed together (self drilling self tapping rubber washered doo dads) from the outside- roof sheets first and apex last - no other way

of doing it due to its design

gazza - yep just 2 skinny pairs of angle irons running each side and about 1m apart so definately not supported enough for this chubby chappie to walk

on...esp now they have lots of fixing holes drilled in them...LOL

Regards

Rob

[Edited on 6/5/12 by robocog]

|

|

|

Slimy38

|

| posted on 6/5/12 at 08:56 PM |

|

|

Couldn't you support it from inside? Two of those extendible post things that builders use to support walls, with a plank or something across

the top under the roof. Then that should give you enough support to be able to get on top and fix the apex.

Alternatively, how about using some other form of fixing? I'm thinking something thick and sticky, then all you need to do is lay the apex on

top. Not 100% on that one though.

|

|

|

907

|

| posted on 6/5/12 at 09:31 PM |

|

|

Could you lay a 3m central and cut the other in half?

Fix the 1.5m piece on working from the end? Same other end?

If you can reach to pop rivet the joints the centre 3m would need little fixing,

being held down by the 1.5m ends.

Paul G

|

|

|

designer

|

| posted on 6/5/12 at 10:45 PM |

|

|

If your roof does not support a normal person, there are not enough roof supports.

|

|

|

Peteff

|

| posted on 6/5/12 at 10:45 PM |

|

|

Fasten the two pieces of apex together with an overlap then drop them on and fasten from each end as well as you can.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

dhutch

|

| posted on 7/5/12 at 07:27 AM |

|

|

How wide are the downs of the corugations, can you not get your foot into it there, standing on the perlins?

Daniel

|

|

|

norm007

|

| posted on 7/5/12 at 08:13 AM |

|

|

In the past I have thrown a sheet of plywood and or several scaffold battens on top of sheets to spread the load.

Something about this, so very wrong.....I have to laugh out loud, I wish I didn`t like this!!!!!!!!!!!!!!

|

|

|

robocog

|

| posted on 7/5/12 at 09:44 AM |

|

|

Perlins are right at the top and bottom (so about a meter unsupported)

Cannot really get my foot into the lower part of the box section (even width wise) and I know I'll crimp crush the upper ridges without much

effort or weight

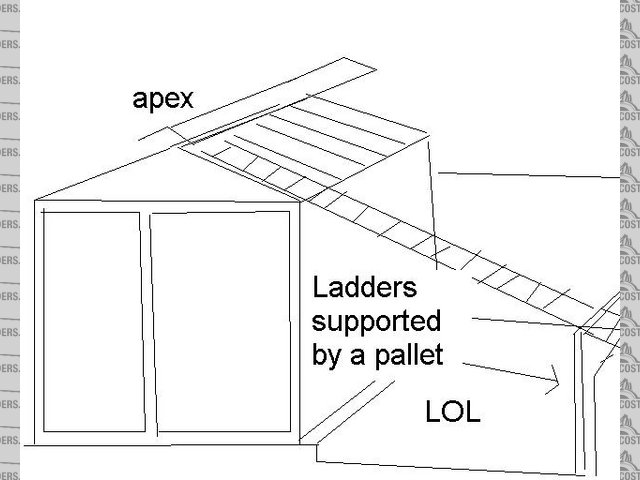

Have popped some pictures showing the construction up + showing how little I could do from the one end (those 4 fixings I managed to put in represent

3/4 of a meter - only another 4 and 1/4 meters to go!

I could probably go about a meter in from that end if I get some taller ladders on the case and some method of holding them off the overhanging roof -

so only one more pair of self tappers

[img]

Description

[/img]

[img]

Description

[/img]

The apex is wider than the top purlins (and covers/hides the fixings) so nothing to walk on there

The lower purlins are a lot lower than my feet - even if I would be happy with the apex wedged in my crack and sat splayed out- so the only parts I

can stand on are very much unsupported

Pic from when I started to dismantle it showing how the purlins run - again the apex is wider than the top purlins so it covers where the sheets

attach to them - also gives nowhere supported to stand

[img]

Description

[/img]

I'm sure if I put some sheet wood to try and spread the weight I'll just slide off ski slope syleee (its very slippery - don't know

if they have coated it in PTFE or something despite the grippy looking leather grain patterns)

I thought the metal would have been thicker and stiffer so I didn't envisage these issues when ordering - assumed I'd be able to shuffle

along on my butt along the apex fixing it down as I went

Have someone who knows someone who does roofs - and waiting to hear back to see if they have any special ladders or euip or even advice

I may be able to borrow some acro props and wedge some sheet from inside...but then I'm not sure it helps if I daren't walk on the ridges

for fear of them crimping and crushing

Regards

Rob

|

|

|

dhutch

|

| posted on 7/5/12 at 10:45 AM |

|

|

I can see you pain, and i dont know what the correct solution is, or what a roofer would do, give its too shallow for the hooks of a cat ladder to

catch. I would be thinking either a 4*4ft bit of of cut ply and some rubber on the back to stop it sliding (it really is quite flat, even if its

slippy a nutsack without something between them) or else back to the ladder and pallet!!

But some gloves on (ripped hands hurt, if it all goes wrong) and have a crack....!

Daniel

|

|

|

Nick DV

|

| posted on 7/5/12 at 11:13 AM |

|

|

Get some scaffold board and wedge in place as close to the apex as possible using a cuple of Acrow jacks - make sure they cannot slip at the top and

bottom. Get another board and knock on a couple of pieces of batten to correspond with the channels and then lay the board over the one below so that

it sits above the ridges - if you know what I mean - protect the roof with a folded dust sheet if you want, and you should be able to quickly fix the

capping. Do this from both ends, work with someone who can check all stays in place below and you should be ok.

Chees, Nick

"The force will be with you, always!"

|

|

|

BenB

|

| posted on 7/5/12 at 11:44 AM |

|

|

If I'm reading it right the problem is fixing the capping piece in place?? Why not do it from the inside? Drill some holes in the capping piece

every foot or so, use some long dome ended bolts through the capping hanging into the roof voice, put some metal bar (or even wood would do) between

those two bars which run the length of the garage, drill holes in the middle of them, bolt goes through the hole, add a nut and tighten.

IE clamp the capping piece in place using those bars that run the length of the garage as something to pull against.

If I've misunderstood please ignore the above

|

|

|

Peteff

|

| posted on 7/5/12 at 12:29 PM |

|

|

Why not take the trusses down and fit the roof to them then put it all back up in one piece ? I bet four of you could lift that and slide it back into

place.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

owelly

|

| posted on 7/5/12 at 12:43 PM |

|

|

INMO, if the roof won't take the weight of you walking on it, it won't last long with a couple of tons of snow on it! You'll need to

put up more steel work, some extra timber supports or be prepared to dash out every hour or so in the winter to sweep the roof!

Good luck.

http://www.ppcmag.co.uk

|

|

|

robocog

|

| posted on 7/5/12 at 04:13 PM |

|

|

LOL, I doubt a couple of tons of snow have fallen on the whole of Gosport put together since the passing of the last ice age

Surrounded by the sea and protected by the IOW and the hills t'other side we hardly ever see it for more than a few seconds

We possibly had as much as 4cm of the stuff last year (most snow recorded evvvaaahhh) and my polyester tonneu cover on the Indy hardly sagged under

the "most extreme conditions" we saw and required no intervention from myself

Honestly - weight of snow is a complete non issue this way and it would be as daft as making the structure kangaroo proof

Sure - If I had the money or lived somewhere more prone to the white stuff I would have a much sturdier structure - but its survived the last few

dacades without collapsing so see no reason why it should suddenly do so

Even if it were to be subject to the next ice age and have its roof buckle and collapse- the worst case scenario would be my stuff getting wet

temporarily - no different to when I work outside and its raining (my only other option) - impact damage aside

Theres no way I'd be inside it if were to be snowing - I'd be a lot closer to some central heating and a kettle- so no loss of life would

occur in the worst case scenario

If it were a dwelling for my loved ones then yes - I would be a bit less casual about it

It's a shed to tinker in and to give the us the dining room back (looks like an autojumble in there)

Regards

Rob

|

|

|

robocog

|

| posted on 7/5/12 at 04:58 PM |

|

|

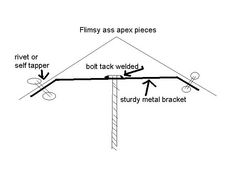

Ben- thats how the original concrete asbestos ridges were held on

It could possibly be done like this again- but the new apex pieces have a neat creased/folded angle (pointy) and the old apex pieces were rounded so

sealing was less of an issue

The metal sheet is also wafer thin and I suspect it would buckle splay and deform before any "clamping" pressure could be put on it - so I

had kind of ruled that one out based on its flimsyness

I suppose I could make some special bolts (as per the diagram) and screw those to the apex and drop it through and nip up from below

[img]

Description

[/img]

I also like the fact if it gets stitched every peak it will help make the whole structure all a lot more rigid so will carry on exploring doing that

(as suggested by the retailer)

Will ring them tomorrow and see if they have a neat solution - it's not like they wont have been asked a million times ..LOL

Regards

Rob

|

|

|

D Beddows

|

| posted on 7/5/12 at 05:05 PM |

|

|

Google 'Sky Hooks' - they're what you need.....or just do it properly, there is no way you can do what you want to in the way you

want without that that roof collapsing as there is no support to it. Possibly you could tek screw from underneath but...

|

|

|

robocog

|

| posted on 11/5/12 at 10:55 PM |

|

|

Well its done

I ended up just manning up and doing it

Turns out its perfectly fine to take my weight along the paper thin apex (I screwed the apex on as I shuffled along on my arse arms length away)

I guess I was basing it being way to flimsy on it not being attached to much, soon as a few more screws went in the structure felt much more solid

I had a "spotter" to make sure nothing was deforming/moving as I slowly went along

All is good and the man cave is pretty much waterproof

It lashed down on Thursday - so its had a very thorough test

Only leaks were from 2 miss drilled holes (easilly filled) and from around the outside creeping in under the walls

I may just haunch some concrete round the outside and silicone/bitchumen the inside

Would like to DPC and screed..but its possibly out of my budget and will delay getting the dining room back

Was great hopping onto a motorbike this morning and not having to wipe it dry first to try and avoid getting to work looking like I peed myself

Regards

Rob

|

|

|