matt_gsxr

|

| posted on 18/5/13 at 07:59 PM |

|

|

Mystery underfueling Megasquirt bec turbo

Hi there,

What have I missed?

I am running gsxr1100 with EFI (gsxr600 TBI) controlled by megasquirt (MS2), I can log using this with my LC-1 measuring AFR's.

Regarding fueling I have an intank Walboro 255 (theoretically 255litres/hour), and 4x s2000 gen1 injectors (theoretically 390cc/min each at 43.5psi),

I have a FSE fuel pressure regulator and a cheap pressure gauge (visual only). With the MS I am running 2 squirts per cycle.

So, I've been tuning up using dual table (multiplied MAP and Alpha-N), the tune is coming together, it comes on boost enthusiastically, idles

nicely and it seems to be quite promising.

The (present) problem that I have is that I am getting >100% duty cycle on my injectors even at relatively modest power demands (i.e. 8psi of boost

7.5kRPM and 100% throttle open). Clearly if I am going to rev higher (i.e. 11k red-line) I am going to be running lean which is not going to work for

long

Previously I have tried to address this by increasing the fuel pressure (presently at 4.5atm+MAP). This doesn't seem to have helped.

So, I don't understand. The injectors are good for ~1.5litres/min at 43.5psi, the fuel pump is good for 4litres/min.

1.5 litre/min of fuel should give me about 240bhp, so what have I done wrong? and these s2000 injectors are used on Busa turbo (so fruitier than my

old engine).

My thoughts.

1) Fuel pressure gauge dodgy

2) Low volts at fuel pump

3) Blocked fuel pump inlet filter

4) Fuel injectors not as described (2nd hand)

My thinking is that I might measure the voltage at the pump to look for lost volts (the Walboro is a turbine type so will be sensitive to low volts).

Next stick a video camera on the pressure gauge as a sort of secondary logging to see if there are pressure drops. Drop the engine to 1 squirt per

cycle which will squeeze some more out of the injectors (less dead time for opening/closing).

Any thoughts appreciated. I am hoping that I have missed something obvious.

Thanks,

Matt

|

|

|

|

|

Ben_Copeland

|

| posted on 18/5/13 at 08:13 PM |

|

|

Send the injectors off to get them cleaned. I sent mine to Mr Injector, he measured them and they were awful. Cleaned and refurbed

Cost about £45

Ben

Locost Map on Google Maps

Z20LET Astra Turbo, into a Haynes

Roadster

Enter Your Details Here

http://www.facebook.com/EquinoxProducts for all your bodywork needs!

|

|

|

coozer

|

| posted on 18/5/13 at 08:18 PM |

|

|

Dont think the voltage at the pump has anything to do with the duty cycle.. after all theres nothing measuring how much fuel is going in..

however..

Voltage drop at the injectors can slow the opening therefore reducing the fuel going in..

My other thinking is.. are you using a lambda fir the AFR closed loop? If this is closed loop controlling the fueling I would look there first.. are

you able to communicate to the LC1? Is the lambda set up on the right channel?

I'm just getting back onto my MS2 applying it to a Rover V8....

1972 V8 Jago

1980 Z750

|

|

|

baz-R

|

| posted on 18/5/13 at 08:20 PM |

|

|

ask a stupid question you are rising the fuel pressure with boost by having the small pipe conected to port pressure?

a fixed pressure system will not work boosted.

if your pump is not keeping up you would see it as fuel pressure drop

are you also looking at actual inj duty cycle in ms or you may not have your inj settings right like pwm set too low or somthing?

|

|

|

matt_gsxr

|

| posted on 18/5/13 at 08:28 PM |

|

|

Good thoughts:

Just to add some details

My pressure regulator is MAP referenced (it has a port on the top that is plugged into my MAP line)

I am not running closed loop, so the AFR is simply diagnostic.

Megasquirt outputs a dutycycle (which is the desired pulsewidth as a fraction of the available time) which is what I am talking about

My logic is that if you autotune then all megasquirt can do is increase opening times (via the fuel map), if you run out of fuel pressure/flow then

the table values keep increasing but to no avail.

I did clean and DIY test the injectors before I put them in (fuel injector cleaner and the ultrasonic cleaner at work, shh!)

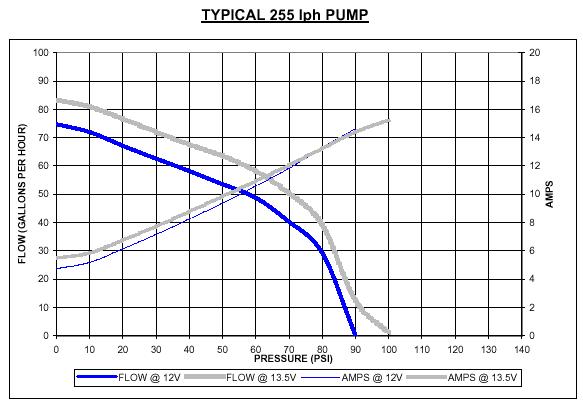

My concern about pump volts came from this:

Showing the higher voltage gives increased flow, which made me wonder what would happen at reduced voltage.

|

|

|

matt_gsxr

|

| posted on 18/5/13 at 08:30 PM |

|

|

Oh and injectors are 14Ohm, so no PWM for me. I am driving them all off one driver though, so remaking the loom is a good idea to speed up the

switching (and easy too).

Thanks for all these good ideas.

|

|

|

baz-R

|

| posted on 18/5/13 at 08:46 PM |

|

|

all on 1 driver? so you are running batch fire? this may not be so good for your fuel pressure regulation

could you not use both of your drivers (1+4 & 2+3) alternating

i also run a 15A fuse for each bank and twined up feed cables

|

|

|

matt_gsxr

|

| posted on 18/5/13 at 09:22 PM |

|

|

quote:

Originally posted by baz-R

all on 1 driver? so you are running batch fire? this may not be so good for your fuel pressure regulation

could you not use both of your drivers (1+4 & 2+3) alternating

i also run a 15A fuse for each bank and twined up feed cables

Interesting, I am running 2 squirt per cycle and the RPM's are always going to be above 1k. This has been working like this for a long time but

I have worried about the reliability of my FPR before.

Anyway, I am at this very moment building a second injector loom (1+4 on 1 driver and 2+4 on the other). I already wired up the drivers to MS as I

was running staged injection and I have all the parts to hand, so I can build this and test tomorrow.

|

|

|

turboben

|

| posted on 18/5/13 at 09:25 PM |

|

|

I hope your batch firing - if not you'll be firing nothing on every other alternation. That would half your available fuel.

|

|

|

dimlaz

|

| posted on 19/5/13 at 05:42 AM |

|

|

hi

check your inlet pipe from the tank to the pump.

maybe isn't strong (if its rubber pipe) and you have a hugh vaacum from this pump.

this pipe is right to be plastic or metalic not rubber.

|

|

|

jeffw

|

| posted on 19/5/13 at 07:44 AM |

|

|

Get rid of the FSE FPR and fit a fixed Bosch 3.5 Bar reg. This is what you should be running. What power are you expecting from the engine/turbo

combo?

|

|

|

ashg

|

| posted on 19/5/13 at 08:18 AM |

|

|

sounds like you have got too much resolution in your fuel table. im guessing that because your engine is pretty small the required fuel value is

pretty low.

forget duty cycle on the injectors for now and look at the pulesewidth. at idle you should be at around 2.5ms any lower and i doubt it will run

well.

just for a reference my required fuel is around 10 on the 2.0 turbo saab, i would guess you will need to be in that ball park if your looking at

making 200hp upwards. it will make getting a good idle a little harder but should give you a bit more fuel up top.

Anything With Tits or Wheels Will cost you MONEY!!

Haynes Roadster (Finished)

Exocet (Finished & Sold)

New Project (Started)

|

|

|

matt_gsxr

|

| posted on 19/5/13 at 01:29 PM |

|

|

quote:

Originally posted by jeffw

Get rid of the FSE FPR and fit a fixed Bosch 3.5 Bar reg. This is what you should be running. What power are you expecting from the engine/turbo

combo?

I do worry about the FSE regulator, but I am a tight git!

So am keen to eliminate other potential issues.

Target is 250bhp which is probably realistic, but really if I get 9psi with well behaved AFR and it doesn't overheat then I will be happy to

just try to use it for a while, anything >200bhp in <500kg is more than enough for me. I have been running up to 6kRPM for a while (trigger

wheel issue, now fixed) and it was mental already, so now I have double the rev range...

|

|

|

matt_gsxr

|

| posted on 19/5/13 at 01:41 PM |

|

|

quote:

Originally posted by ashg

sounds like you have got too much resolution in your fuel table. im guessing that because your engine is pretty small the required fuel value is

pretty low.

forget duty cycle on the injectors for now and look at the pulesewidth. at idle you should be at around 2.5ms any lower and i doubt it will run

well.

just for a reference my required fuel is around 10 on the 2.0 turbo saab, i would guess you will need to be in that ball park if your looking at

making 200hp upwards. it will make getting a good idle a little harder but should give you a bit more fuel up top.

I don't completely understand the message here.

But to answer your question, running 2 squirts per cycle I have 2.0ms injector pulses at idle (1200rpm, closed throttle, MAP=67kPa), the idle is

stable (for a bike engine with all the counter weights removed from the crank!).

At 12kRPM, the time for each crank cycle is 5ms, so if I req fuel is 10ms then I don't think there is time to fit all that fuel in (especially

as on-boost fueling increases above req fuel). My req fuel is 5.4ms, as my engine is ~50% of the capacity of your Saab but revs ~200% higher those

numbers sort of agree.

Matt

|

|

|

matt_gsxr

|

| posted on 19/5/13 at 01:46 PM |

|

|

quote:

Originally posted by dimlaz

hi

check your inlet pipe from the tank to the pump.

maybe isn't strong (if its rubber pipe) and you have a hugh vaacum from this pump.

this pipe is right to be plastic or metalic not rubber.

It is an in-tank pump so only has one of those little inlet filter bag things (from the original gsxr1000 fuel pump as walboro 255 is a pretty decent

match). The filter is pretty small though, I may measure the flow rate by putting a bucket/stopwatch on the outlet to the regulator.

|

|

|

matt_gsxr

|

| posted on 19/5/13 at 01:53 PM |

|

|

quote:

Originally posted by matt_gsxr

quote:

Originally posted by baz-R

all on 1 driver? so you are running batch fire? this may not be so good for your fuel pressure regulation

could you not use both of your drivers (1+4 & 2+3) alternating

i also run a 15A fuse for each bank and twined up feed cables

Interesting, I am running 2 squirt per cycle and the RPM's are always going to be above 1k. This has been working like this for a long time but

I have worried about the reliability of my FPR before.

Anyway, I am at this very moment building a second injector loom (1+4 on 1 driver and 2+4 on the other). I already wired up the drivers to MS as I

was running staged injection and I have all the parts to hand, so I can build this and test tomorrow.

Just a quick update. Adding the 14 plus 23 as separate drivers made no difference at idle. Swaping from simultaneous (2 squirts per cycle) to

alternating (1 squirt per cycle) required me to decrease the fueling but 5% to maintain the AFR.

I guess that means that my switching time was out by a little. Anyway more experiments to perform before I have to start splashing the cash with

injector cleaning and new FPR.

Thanks for everyone's help with this.

|

|

|

MikeRJ

|

| posted on 19/5/13 at 02:56 PM |

|

|

quote:

Originally posted by coozer

Dont think the voltage at the pump has anything to do with the duty cycle.. after all theres nothing measuring how much fuel is going in..

however..

If the pump voltage is low then it's flow rate will also be down. At high engine load (and hence high fuel flow) the fuel pressure will drop

and larger duty cycles will be needed to get the required fuel. The fact that increasing the static fuel pressure shows no reduction in the required

injector duty cycle suggests that restricted fuel flow could well be the problem (though could be caused by issues other than voltage, e.g. partially

blocked pipe or filters).

|

|

|

matt_gsxr

|

| posted on 19/5/13 at 04:12 PM |

|

|

So, the plot thickens my sleuth-like friends.

I measured the flow rate in the return line (fuel system is Tank-pump-longhose-fuelrail-regulator-returnline) and in 30seconds it filled a 4pint milk

carton. I did this by mass and got 1440grammes in 30seconds, so 4litres/minute.

4litres/minute = 240litre/min. And all this was with the engine off (so volts around 12v rather than the running value of 13.5v), which puts me about

on the line in the graph (above) depending on whether the y-axis is 'merican or Imperial gallons.

So to my mind this eliminates:

Voltage at the pump

Blocked hoses and filters

Which leaves me with dodgy injectors, or dodgy pressure regulator;

The SBD site does suggest that these FSE FPR are good only to 215bhp (

http://www.sbdev.co.uk/Fuel_Systems/Fuel_Pressure_Regulars/Fuel_Pressure_Regulars.htm ), and I don't trust the pressure gauge (it came with a

previous super cheap FPR).

And the injectors came from a bloke in the USA who was 'breaking an s2000'.

Time to rebuild my fuel injector testing jig (fire brigade on standby!)

Matt

|

|

|

MikeRJ

|

| posted on 19/5/13 at 06:30 PM |

|

|

Have you checked the plugs to ensure all cylinders are running approximately equal AFR?

Is the engine definately not running rich when it hits 100% (ignoring the AFR meter, e.g. black exhaust smoke etc)?

[Edited on 19/5/13 by MikeRJ]

|

|

|

baz-R

|

| posted on 19/5/13 at 06:37 PM |

|

|

quote:

Originally posted by matt_gsxr

quote:

Originally posted by baz-R

all on 1 driver? so you are running batch fire? this may not be so good for your fuel pressure regulation

could you not use both of your drivers (1+4 & 2+3) alternating

i also run a 15A fuse for each bank and twined up feed cables

Interesting, I am running 2 squirt per cycle and the RPM's are always going to be above 1k. This has been working like this for a long time but

I have worried about the reliability of my FPR before.

Anyway, I am at this very moment building a second injector loom (1+4 on 1 driver and 2+4 on the other). I already wired up the drivers to MS as I

was running staged injection and I have all the parts to hand, so I can build this and test tomorrow.

if you run big injectors in a batch fire what happens is when your running high duty's the reg has trouble reacting to rise pressure then by the

time it gets there you shut all your injectors and it dumps back to tank lowering your overall fuel pressure or flickering pressure.

as for what ashg says im pritty sure some of the softwares and firmwares give you estimated duty but im sure there was a way of reading actual duty

but i think it requires your inj setting to be spot on.

easy way is to look at open time like he says.

|

|

|

matt_gsxr

|

| posted on 19/5/13 at 11:22 PM |

|

|

The DutyCycle that my Megalogviewer is putting out is equal to:

[Field.pulseWidth] * [Field.RPM] / 600

So basically the pulsewidth divided by the time for one crank cycle.

I think the opening time is wrapped into the pulsewidth.

No opportunity for high power tests of revised injector wiring, but hopefully I can test the injectors this week and maybe source a replacement FPR.

Matt

|

|

|

coyoteboy

|

| posted on 20/5/13 at 12:17 PM |

|

|

The other problem you can see is pressure drop along the rail at high flow rates which would lean out the cyls as you progress from the pump.

What's the bore on your rail?

|

|

|

dave_424

|

| posted on 20/5/13 at 12:30 PM |

|

|

With a small ish rail, 4 big injectors firing at once and a FPR with a pretty small flow, you must be getting a considerable drop in fuel pressure,

can you see fuel pressure whilst driving and boosting?

Fuel can only flow to your injectors as fast as it can leave your rail through your FPR, invest in one with a much higher BHP/flow rating

Going from all 4 firing to 2 and 2 will help you out.

|

|

|

matt_gsxr

|

| posted on 20/5/13 at 12:31 PM |

|

|

quote:

Originally posted by coyoteboy

The other problem you can see is pressure drop along the rail at high flow rates which would lean out the cyls as you progress from the pump.

What's the bore on your rail?

Rail is rather massive 0.690inch, so I don't think that is the issue.

Fuel line from the pump at the rear is narrower 8mm, but it isn't an issue.

As an update from the original question; I measured the flow out of the bottom of the regulator (i.e. return line) and I get 4 litres/min so I am

fairly sure that my problem isn't the pump. Unless it is doing something funny when the injectors are going full chat.

I have ordered a new regulator (Bosch based), and will give the injectors a check through over the week.

|

|

|

BaileyPerformance

|

| posted on 20/5/13 at 02:07 PM |

|

|

we have seen small injectors "max out" according to tunerstudio on high revving engines, we did a cosworth YB NA some years ago, made

262BHP at around 9K, we used 412cc injectors but these where 90% at high RPM - changed them for 625cc to reduce duty to 60%

In theory the 412cc injectors are plenty big enough for that sort of power....

so, on higher revving engines its not always a fuel delivery issue but a timing issue - at high RPM there is not enough time to open, then close a

small injector. A larger injector does not require as much open time to deliver the right amount of fuel therefore more time is available.

If i was you i would use larger injectors or more fuel pressure (and lower reg_fuel) this will lower the duty.

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|