Avoneer

|

| posted on 25/1/05 at 11:30 PM |

|

|

8mm bolts for bones?

Are 8mm bolts ok for the bones?

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

|

|

JoelP

|

| posted on 25/1/05 at 11:46 PM |

|

|

most people use bigger bolts, you can read into that whatever you like! is there a need to use 8mm bolts? i would, myself, follow the crowd on this

one unless there was a good reason to deviate. obviously high tensile would be the way to go anyway...

Beware! Bourettes is binfectious.

|

|

|

craig1410

|

| posted on 25/1/05 at 11:52 PM |

|

|

I think 8mm high tensile bolts should be fine but I'm using M10 high tensile (8.8) bolts myself. I think many people are using 1/2" UNF to

fit the commonly available poly bushes.

Hope this helps,

Craig.

|

|

|

Hellfire

|

| posted on 25/1/05 at 11:54 PM |

|

|

Plain shank M12 on the MK Indy IIRC

|

|

|

nick205

|

| posted on 26/1/05 at 08:24 AM |

|

|

Indy does indeed use M12 bolts and the Tiger recomend 1/2" UNF for the Avon.

I'm not sure I'd be comfortable using M8 bolts.

Nick

|

|

|

James

|

| posted on 26/1/05 at 09:19 AM |

|

|

You might of course be better with M8. In an accident the bolt is more likely to snap than an M12 and therefore sacrificing the wishbone but saving

the chassis!

James

|

|

|

Mix

|

| posted on 26/1/05 at 09:29 AM |

|

|

I think most of us just use whatever fits our bushes

Using 8mm high tensile bolts wouldn't concern me.

Mick

|

|

|

indykid

|

| posted on 26/1/05 at 09:37 AM |

|

|

it'd concern me

IMO of course

tom

also pat, the sierra uprights have M12 pinch bolts standard, not M10. are you just trying to save weight?? get some hollow bolts

|

|

|

britishtrident

|

| posted on 26/1/05 at 10:05 AM |

|

|

Triumph wishbones bushes designed for were 3/8" unf bolts.

This is approx 9.5 mm --- regard this as the minimum useable size.

|

|

|

DarrenW

|

| posted on 26/1/05 at 11:47 AM |

|

|

Ive used M12 8.8's including diff mount and engine mounts.

|

|

|

Mix

|

| posted on 26/1/05 at 11:58 AM |

|

|

Just done a quick bit of research, I was bored.

Grade 8 bolt, 8mm diameter has a shear strength of 3,181kg.

This is in single shear. I believe I'm correct in thinking that in our application the bolt is in double shear and hence would have a shear

strength of 6,362kg.

So based on those figures I would be happy with 8mm bolts if that was what my bushes required.

Mick

|

|

|

NS Dev

|

| posted on 26/1/05 at 12:22 PM |

|

|

I quite agree, M8 grade 8.8 or better would be fine, I'd personally use grade 10.9 or 12.9 m8 capheads to get the best quality bolt in there but

see no problem with m8's at all. My car (ST) uses 1/2" unf to suit the bushes but this is ridiculously OTT!!! It's just that they

fit!! If I were being fastidious I'd drill them out through their centrs to lighten them!!

|

|

|

Peteff

|

| posted on 26/1/05 at 02:51 PM |

|

|

Any comments on this.

I find higher grade bolts tend to be more brittle. Instead of bending they shatter under stress so they are not necessarily better in all

applications.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

NS Dev

|

| posted on 26/1/05 at 05:59 PM |

|

|

I feel able to comment on this as I work for a steel manufacturer!

Yes, they will be more "brittle" but then for any sort of shock load experienced on a car they will be fine.

"Brittleness" is measured by impact properties, hardness by hardness test and tensile by tensile test, but in general, all are

linked.....the harder steels are more brittle and have higher tensiles, in fact you can ascertain tensile strength by cross reference from hardnesses,

a good way to check a bolt for a critical application before using it is to harnedd test the centre of it's head and cross reference the tensile

strength............................... however, a grade 12.9 Caphead bolt still has VERY good impact properties, much much much!!!!! stronger than

the welds holding the wishbone brackets to your chassis!! Welds are almost always the weakest point of any structure, unless it has been fully stress

relieved.

So, yes they are more brittle than a grade 8,8 bolt, but when fitted to a bushing made of rubber or plastic, and to a bracket welded to a chassis made

of 1.6mm mild steel, the bolt will be the last bit to let go, rest assured, and then the 8.8 one will break before the 12.9, whatever the nature of

the loading!!!!!!!!!!!!!!!!!!!!!!!!

|

|

|

britishtrident

|

| posted on 26/1/05 at 09:12 PM |

|

|

quote:

Originally posted by Mix

Just done a quick bit of research, I was bored.

Grade 8 bolt, 8mm diameter has a shear strength of 3,181kg.

This is in single shear. I believe I'm correct in thinking that in our application the bolt is in double shear and hence would have a shear

strength of 6,362kg.

So based on those figures I would be happy with 8mm bolts if that was what my bushes required.

Mick

But isn't just in shear it is also in tension -- no production car use bolts smaller than 3/8" ( and the only one that actually uses

3/8" is the Triumph and I suspect the Mini but not at the pivot) and also the bolts should be a close fit in the bush

|

|

|

mattplace

|

| posted on 26/1/05 at 10:50 PM |

|

|

i'm an aircraft engineer and its not the size of the bolt (within reason!) which is the question. its the quality.

you will be amazed at the size of the bolts they use on aircraft.

for example, a pfcu (hydraulic ram) is connected with a 1/4" bolt at either end and that has to cope with tensile stress and shear loads at

3500psi of pressure. if that bolt fails, the aircraft would go down!!!

oh, and a harrier gr7's (jumpjet) complete wing is held on by six 3/8" to 1/2" bolts!!!

think of that when u are all flying off to sunny spain in august!

|

|

|

NS Dev

|

| posted on 27/1/05 at 12:12 AM |

|

|

NIce one Mattplace.

It's something I have to keep reminding myself when designing (posh word for scraps of paper!!) car stuff, keep aeroplanes and Colin Chapman

firmly in mind. Apparently he always quoted something about what a 1/4" bolt could lift, and if you look at a lot of circuit race cars they are

held together by VERY skinny bolts.

I'm not saying that we shouldn't build a decent safety margin into locosts, and I would suggest erring on the larger size for bolts when

unsure, but it'sa always worth considering the stresses involved and what other parts of the structure they are fed through. Often the bolt is

disproportionally strong compared to the rest of the structure.

Bear in mind that a grade 10.9 bolt has more tensile strength than any steel that you or I can buy in the un heat-treated condition, so it's

strength when compared cross-section to cross section to a weld, for example, is huge!

|

|

|

Rorty

|

posted on 27/1/05 at 05:28 AM posted on 27/1/05 at 05:28 AM |

|

|

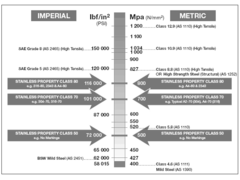

Mix and NS Dev, there's no such thing as M8 Grade bolts. You're confusing two entirely different standards.

The reason I mention this is there are real differences and the grading systems are not interchangeable.

The term "Grade" is used for imperial (SAE etc.) fasteners and the distinctions are Grades 5, 8 etc.

Metric fasteners are distinguished by "Class" such as Class 8.8, 10.9 and 12.9.

A common mistake is the substitution of Class 8.8 fasteners when Grade 8 is specified; people see the “8.8” marking and think it’s Grade 8. The

difference in tensile strength is 25% and could potentially spell disaster if they are mixed up.

Grade 5 is roughly the equivalent of Class 8.8 and Grade 8 is roughly the equivalent of Class 10.9.

I often use 1/2" fasteners for wishbones purely for convenience when using over the counter bushes etc. If I'm making my own bushes

I'll step the M16 rod ends on the front uprights down to 10mm and use Class 10.9 10mm fasteners throughout.

I only use Class 12.9 for the CV screws.

Rescued attachment impmetric_comparison.gif

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Mix

|

| posted on 27/1/05 at 09:19 AM |

|

|

Rorty

Thanks for pointing that out.

My results were arrived at by taking the properties of SAE grade 8 steel, (tensile strength 150,00 psi) and converting them to a bolt of 8mm cross

section. I see from your table that this equates to a class 10.9 M8 bolt.

I still would have no reservations about using M8 bolts as suspension pivots however.

British Trident

Yes I know the bolt would also be in tension but as shear strength is calculated as 60 percent of tensile strength I didn't think it relevent.

There is also the frictional force due to 'clamp up' of the bracket / bush tube, (runs for cover) which acts in favour of the shear

strength, (if you get what I mean).

Mick

PS That means an M8 class 8.8 bolt in double shear will fail at over 5 tonnes, disregarding the clamp up friction.

Don't think that's going to be the weakest point.

[Edited on 27/1/05 by Mix]

|

|

|

NS Dev

|

posted on 27/1/05 at 10:00 AM posted on 27/1/05 at 10:00 AM |

|

|

I never said there was such thing as an M8 grade bolt!!!!!!!!!!!!!!!!!

Please read my post properly!!!!

I do know a fair amount as I work for a company tha tmanufactures engineering alloyed steels!!

M8 is spec for dimension, I said GRADE 8.8, 10.9 or 12.9, as in Ultimate Tensile Strength grades, I did not say GRADE 8!!! I am not completely

stupid!!!!!!!!!!!!!!!!..........read properly!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

If you check that your bolt has 8.8, 10.9 or 12.9 stamped on it then that's what you have got!!!!!!!!!!!!!!!

[Edited on 27/1/05 by NS Dev]

|

|

|

Rorty

|

| posted on 27/1/05 at 12:12 PM |

|

|

quote:

Originally posted by NS Dev

I never said there was such thing as an M8 grade bolt!!!!!!!!!!!!!!!!!

I really don't mind! I was only making the point for clarity and safety; not critisizing, or intending to cause three grumpy faces.

However, you did say:

quote:

Originally posted by NS Dev

I quite agree, M8 grade 8.8 or better would be fine...

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

12a RX-7

|

| posted on 27/1/05 at 12:36 PM |

|

|

Don't forget you need to account for fatigue. How many cycles do you want your bolt to last ? for a car I would suggest aiming for an infinite

life as even a full on clubman racer is going to find it difficult to justify the weight saved by using an M8 bolt that needs to be changed after so

many hours running over an M12 which will last the full life.

That is the reason a military jet can run with seemingly small bolts for high loadings, they are maintained without fail and at very strict

intervals.

A bolt is almost never in straight shear either, if there is a clearance (the wishbone moves so there must be) you are also putting a bending stress

into the bolt across the clearance. This can result in significant reduction in bolt failure load, there is also the bolt tension to consider from

torqe tightening.

What load does a mass of 6800 odd Kg equal then ? are we using gravity to determine the force in Newtons ? don't forget that although a locost

may only have a mass 600Kg a 10G or more shockload through the suspension will not be an unlikely scenario.

|

|

|

britishtrident

|

| posted on 27/1/05 at 01:21 PM |

|

|

quote:

Originally posted by 12a RX-7

Don't forget you need to account for fatigue. How many cycles do you want your bolt to last ? for a car I would suggest aiming for an infinite

life as even a full on clubman racer is going to find it difficult to justify the weight saved by using an M8 bolt that needs to be changed after so

many hours running over an M12 which will last the full life.

That is the reason a military jet can run with seemingly small bolts for high loadings, they are maintained without fail and at very strict

intervals.

A bolt is almost never in straight shear either, if there is a clearance (the wishbone moves so there must be) you are also putting a bending stress

into the bolt across the clearance. This can result in significant reduction in bolt failure load, there is also the bolt tension to consider from

torqe tightening.

What load does a mass of 6800 odd Kg equal then ? are we using gravity to determine the force in Newtons ? don't forget that although a locost

may only have a mass 600Kg a 10G or more shockload through the suspension will not be an unlikely scenario.

My understanding was the OP had bushes to Triumph dimensions these have a hole just a fraction too small for a 10mm dia bolt.

Using over over large dia bolt also brings problems the bolt has to to have enough strain when tightened to prevent it slackening or fretting --- ie

a 8 mm bolt tighten to 15 ft lbs is tight enough but a 12 mm bolt tightened to 15 ft lbs is not tight enough and will loosen.

Properly tightened a bolt in double shear will have very little bending force on it as the inner tube of the bush is held tightly resulting in a

friction joint between the tube and the bracket. By implication this also means If properly tight It should have little or no shearing loads --- but

of course the worse case scenario of having both a slack bolt and hiting a kerb hard has to be allowed for .

Fatigue isn't really a major consideration with any decent high tensile steel unless it operating well beyond any sensible design limmit. And

in any case if he bolt is properly tightened and in hence under tension it won't see any load reversals even if it was subject to bending ---

no load reversals no fatigue.

[Edited on 27/1/05 by britishtrident]

|

|

|

Mix

|

| posted on 27/1/05 at 01:31 PM |

|

|

A bolt is almost never in straight shear either, if there is a clearance (the wishbone moves so there must be) you are also putting a bending stress

into the bolt across the clearance.

Most believe that there should no clearance between the bracket and crush tube.

Mick

|

|

|

NS Dev

|

| posted on 27/1/05 at 01:46 PM |

|

|

that's right, there should definitely be no clearance between the bush tube and the bracket, the tube must be clamped so that the bushes rotate

on the tube, and not the whole lot on the bolt, or the bolt will wear out! (I know this is pointing out the obvious, but I've said it

anyway!)

As you say Mix, for the wishbone to pivot there must be some clearance and thus some bending load, but not a great deal.

I don;t think anybody is advocating loading bolts to the sort of levels seen on aircraft, certainly this wouldn't be wise as the quality levels

are a bit different!! but nonetheless, it's just worth bearing in mind what sort of size bolt is actually needed for an application. (says me

who has 1/2" UNF wishbone bolts..................one wishbone bolt would pick up my car, two passengers, and another one chained on to it

too!!!!)

|

|

|