peter030371

|

| posted on 4/3/22 at 10:53 AM |

|

|

Aluminium Profile

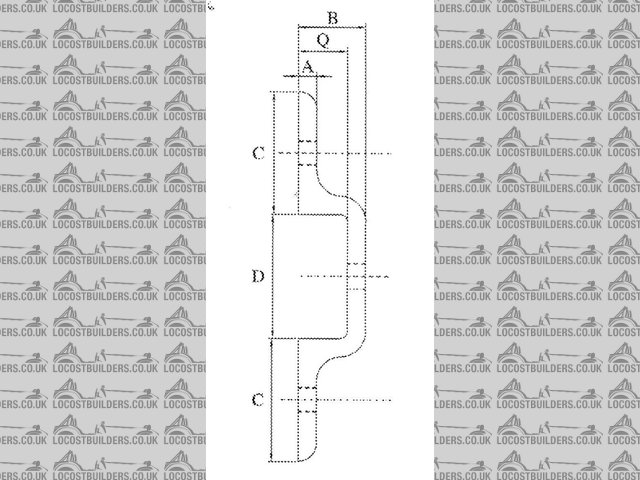

I am looking for some aluminium profile for a little project I want to make. I know you can get 'top hat' profile but can't quite

find what I want..so close but each one I look at one of the dimensions I need it not right. This (rubbish) picture shows the profile in cross

section;

profile

Not too worried about some of the dimensions but D needs to be 30.5mm to 31.5mm and Q 16-20mm. I would expect A to be 2-5mm and C 30-40mm but I can

work with different sizes on these two. The nice soft radii are also not critical. I only need two or three 1m lengths in total.

Can any of your clever people point me in the direction of someone that has something like this off the shelf? I order tons of custom aluminium

extrusion every year at work but none of these suppliers have something like this. I know someone does as I got this image from a Spanish company but

they are now and ex-company

|

|

|

|

|

indykid

|

| posted on 5/3/22 at 08:57 AM |

|

|

Can you get someone to press brake you some up from sheet?

|

|

|

watsonpj

|

| posted on 5/3/22 at 05:16 PM |

|

|

if you can't find it then

2 bits of unequal angle and a bit of flat bar will do it. Then Tig and lumiweld together, i have made a few things with lumiweld and if you get it

clean first its very strong.

https://www.aluminium-online.co.uk/

Pete

|

|

|

peter030371

|

| posted on 7/3/22 at 12:42 PM |

|

|

I will look into pressing it, that might work if my local machine shop has a press brake suitable.

I have a 'tame' welder but asking him to TIG several m together will cost more beer than I think the job warrants.

|

|

|

Mike Wood

|

| posted on 8/3/22 at 07:25 AM |

|

|

Hi

What is the project?

Why not re-design your structure (including spacing between T sections if you were intending to use smaller ones?) to use readily available section

(e.g. used in van/truck bodies) to make it easier and possibly cheaper to buy bits as well as helping any later repair or modification?

Or switch material if structurally small sections suit? I.e. could you use a wood frame with a glued thin plywood skin, and even with a fibreglass

covering (or use the wood to make a mould). It is amazing how you can laminate corrugated card sections (as well as plywood) into grp flat panels to

improve structural rigidity.

Cheers

Mike

|

|

|

coyoteboy

|

| posted on 9/3/22 at 07:02 PM |

|

|

If you go down the pressed route, checkout Fractory. I was expecting them to be nuts prices but they actually quoted almost exactly the same price as

a local jobbing shop cutting a 1m diameter circle from a 3mm thick stainless plate, and doing some minor welding.

|

|

|