Jumpy Guy

|

| posted on 11/12/05 at 05:44 PM |

|

|

putting nuts and inserts in RHS - technique?

I need a threaded bit in the centre of some RHS..

how best to do this?

do i drill a big hole, then weld a nut? or some sort of solid insert, then drill and tap?

[Edited on 13/12/05 by Jumpy Guy]

|

|

|

|

|

Deckman001

|

| posted on 11/12/05 at 05:46 PM |

|

|

Try a Rivnut, you'll need a special tool and fitting but it's quick for the job you need

Jason

|

|

|

Jumpy Guy

|

| posted on 11/12/05 at 06:04 PM |

|

|

i dont think a rivnut will be strong enough; its for one of my seat mounts....

but as an afterthought- has anyone welded a rivnut in? does it work?

[Edited on 11/12/05 by Jumpy Guy]

|

|

|

britishtrident

|

| posted on 11/12/05 at 06:10 PM |

|

|

You need to weld tube throught then tap it .

|

|

|

Chippy

|

| posted on 11/12/05 at 06:18 PM |

|

|

My seats are attached with riv nuts, no problems. If you use the steel riv nuts, not the alloy ones. You can actualy set them with a machine screw,

some washers and a nut, to save buying a setting tool just for a couple.

|

|

|

calvin

|

| posted on 12/12/05 at 05:39 AM |

|

|

There are other sources, but you should consider something like this for something critical like seat mounts

http://www.aircraftspruce.com/catalog/hapages/anchornuts.php

Calvin

http://racecarstuff.com

|

|

|

Jumpy Guy

|

| posted on 12/12/05 at 09:46 AM |

|

|

are these rivet-in stlye fixings better/more secure than a Rivnut?

anyone know?

|

|

|

Steve Hnz

|

| posted on 12/12/05 at 11:00 AM |

|

|

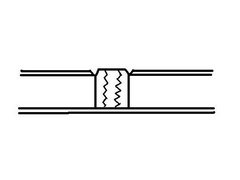

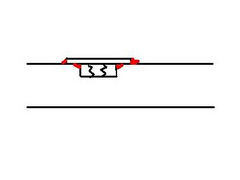

Try something like this, a hole in a short length of 12mm rod, drilled & tapped to 8mm, set into a 12mm hole in the RHS, weld into place, chamfer

both edges of hole to give strength to weld. Grind weld off flush afterwards. You could go to 10mm thread in 14mm rod if you wanted more meat but I

think it would be overkill. Also hole harder to drill & tap bigger & more expensive. Probably necessary to chase threads after welding as heat

tends to shrink holes. Hope that sketch will help to make it clear.

Steve

Rescued attachment Threaded insert.jpg

|

|

|

kb58

|

| posted on 12/12/05 at 03:06 PM |

|

|

IMHO a tube should be welded in instead of inserts.

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

iank

|

| posted on 12/12/05 at 03:43 PM |

|

|

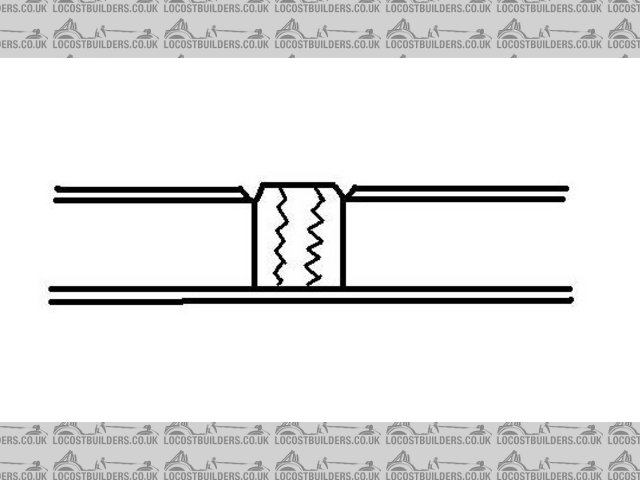

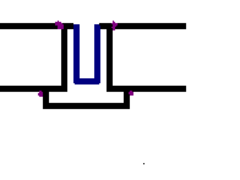

Stronger to use a top-hat arrangement I think... something like:

tophatbush

(grr Paint is awful - blue is the threaded bit, purple the weld/braze)

If you can braze it rather than welding there shouldn't be any distortion to worry about.

|

|

|

Alan B

|

| posted on 12/12/05 at 08:39 PM |

|

|

quote:

Originally posted by kb58

IMHO a tube should be welded in instead of inserts.

Agreed 100%

You have an insert spin on you and then see how much you like them..

|

|

|

Steve Hnz

|

| posted on 12/12/05 at 09:47 PM |

|

|

quote:

Originally posted by iank

Stronger to use a top-hat arrangement I think... something like:

tophatbush

(grr Paint is awful - blue is the threaded bit, purple the weld/braze)

If you can braze it rather than welding there shouldn't be any distortion to worry about.

Whilst the top hat arrangment will certainly be very strong it will also be harder to produce & is probably overkill. The arrangement in the

sketch in my 1st post should be well strong enough, if this rips out its likely to be the least of your problems at the time  , if further strength

was felt to be needed, then just drill right thru the RHS, make your piece of rod slightly longer & weld both sides. , if further strength

was felt to be needed, then just drill right thru the RHS, make your piece of rod slightly longer & weld both sides.

Steve

[Edited on 14/12/05 by Steve Hnz]

|

|

|

Jumpy Guy

|

| posted on 13/12/05 at 07:55 PM |

|

|

OK, another question on the same subject-

i need to raise my seats about an inch or so. New Triton seats with bush at each corner to bolt mount into .

so, whaddya think? do i need a 1" high runner between each corner mounting point, or will one wee RHS block under each point be stable

enough?

hard to describe, anyone have any ideas?

|

|

|

Steve Hnz

|

| posted on 14/12/05 at 09:46 AM |

|

|

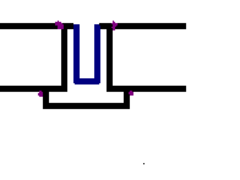

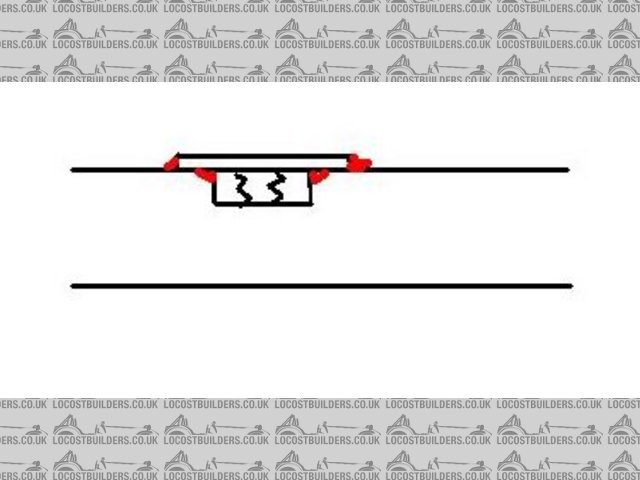

If you have a cross piece of 1" x 1" under the front & back of your seat already & if you were to weld a short section of 1"

squ RHS on top of that ( assuming the open ends top & bottom) & if you were to have a small square of 3mm thick plate, predrilled & with a

captive nut for your seat mounts welded underneath, & then weld this to the top of your short bits of RHS, then I reckon you'd have some

well strong seat mounts, & without the hassle of drilling & tapping rod. In fact the answer to you problem could save you some hassle &

still look nice & tidy. All this assumes though that you have said cross pieces & that they're the correct distance apart for your seat

mounts. Even if they're not you could still drill bigger holes in whatever you end up with & weld the plate with captive nut to your RHS as

an alternative to previously suggested methods. HTH.

Cheers, Steve

|

|

|

Steve Hnz

|

| posted on 14/12/05 at 09:55 AM |

|

|

Quick sketch of what I had in mind, could be flat on tube or on top of short piece of RHS on end.

Cheers, Steve.

Rescued attachment Captive nut.jpg

|

|

|

Nisseven

|

| posted on 14/12/05 at 10:13 AM |

|

|

Steve,

Why not use the short sections of rhs, cut the ends at an angle, drill right size hole for bolt, hold nut on inside of tube with a nut and reach in

with the mig and spot weld the nut. I'd cap the ends of the tubes though.

Bruce.

|

|

|

Steve Hnz

|

| posted on 14/12/05 at 10:29 AM |

|

|

Bruce, that was similar to my original thought to this problem but then I thought that you've two ends to plug after welding in nut. By doing it

on end, one open end of the RHS will be welded right around onto the X-member, & the other plugged by a piece of steel with a hole & captive

nut already in place. I guess I thought this would be easier. My suggestion of 3mm steel for this is probably overkill, but 2-3mm OK, easy to source

from any engineering shop as 25mm wide flat. In truth I don't think there's much in it, just I liked my way better, but then I would eh!

Steve.

|

|

|

Schrodinger

|

| posted on 14/12/05 at 01:13 PM |

|

|

I'm not realy sure why you need to have a meaty fixing for your seats that would require anything much more than a Rivnut.

What loading will it take if you are in an accident? You are sat on top of it and strapped in with your seat belts the seat isn't going very far

IMHO.

regards

Keith

|

|

|

Steve Hnz

|

| posted on 15/12/05 at 09:53 AM |

|

|

Keith, while in theory what you say may seem true, there is a surprising amount of stress on seat mounts caused by simply climbing in & out,

travelling over bumps & around corners, good strong mounts are essential in my mind to prevent the possibility of a seat coming free & causing

loss of control. I'm sure there are those who will Poo Poo this but heck, I'm just a belts & braces kind of guy & can't see

the point in going light when good strong solutions are very simple & contribute a neglible amount to all up weight. This is one area not to save

weight in to my mind.

Steve.

[Edited on 15/12/05 by Steve Hnz]

|

|

|

Mix

|

| posted on 15/12/05 at 10:01 AM |

|

|

And don't forget the possibility of a rear end shunt when all the loading goes through the seat and it's mounts, not the harness.

Mick

|

|

|

andkilde

|

| posted on 18/12/05 at 05:39 PM |

|

|

quote:

Originally posted by Jumpy Guy

are these rivet-in stlye fixings better/more secure than a Rivnut?

anyone know?

Those riveteted nut-plates go in from the backside, they are potentially more secure than Rivnuts but likely difficult to install -- I've only

ever seen them used in a piece of sheetmetal.

Cheers, Ted

[Edited on 18/12/05 by andkilde]

|

|

|

JB

|

| posted on 18/12/05 at 07:04 PM |

|

|

Seat belt Mounts

My normal method for installing seat belts mounts is as follows:

Get a piece of 3mm thick steel about 50mm x 100mm (size depends on the chassis rail) , drill a 7/16" hole in the middle, weld a 7/16" UNF

nut on.

7/16" UNF is the thread to suit harness eyes.

Drill some more 6mm holes in the plate (for rossette welds).

Then I will cut a hole in the chassis rail for the nut, and site the plate onto the chassis rail and weld it into place, including welding through the

6mm holes.

I also try to arrange the plate so it is in shear and not tension. In other words weld the plate on the side of the rail and not the top for the waist

belts.

John

|

|

|

DIY Si

|

| posted on 4/1/06 at 09:26 PM |

|

|

I agree with the talented Mr Beardmore. Always done things that way and haven't once fallen out of a harness yet

I've always used 3mm plate, but purely because i seem to have lots lying about

PS Keep up the good work John.

|

|

|

02GF74

|

| posted on 5/1/06 at 09:44 AM |

|

|

quote:

Originally posted by Jumpy Guy

I need a threaded bit in the centre of some RHS..

how best to do this?

the best way is to buy the expensive insertion tool but you can get away with using a bolt and a drilled out nut; description is

here:

|

|

|