Delinquent

|

| posted on 31/8/07 at 12:57 PM |

|

|

front splitter differs on most of the pics?

|

|

|

|

|

Dale

|

| posted on 31/8/07 at 01:11 PM |

|

|

Gentle curve downward on the door?

Dale

Thanks

Dale

my 14 and11 year old boys 22

and 19 now want to drive but have to be 25 before insurance will allow. Finally on the road

|

|

|

sgraber

|

| posted on 31/8/07 at 01:42 PM |

|

|

c'mon - tell us already !

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

Fred W B

|

| posted on 31/8/07 at 02:13 PM |

|

|

All right - look at the length of the tail of the body aft of the rear wheel arch. It's most apparent if you look backwards along in line with

the top of the rear tyre.

I could not understand that no matter what I did with the blend of the rear lower section into the rear panel with the holes I could not get it to

look right.

As far as I can tell from scaling photo's I have to shorten my plug behind the rear arch by about 160 to 170 mm

Cheers

Fred W B

[Edited on 31/8/07 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

RazMan

|

| posted on 31/8/07 at 02:36 PM |

|

|

Ahhh I see it now - the tail section is noticeably shorter now that you mention it.

A bit of cut'n'shut needed then Fred?

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

sgraber

|

| posted on 31/8/07 at 03:31 PM |

|

|

yes, I see it now too. Very subtle indeed.

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

adithorp

|

| posted on 31/8/07 at 08:10 PM |

|

|

So why would the models be wrong?

There wasn't a special body work for some events was there? Not sure about now but endurence race cars ran different bodywork for Le-Mans due

to the sustained high speeds down the strieght, back in the '80s when I used to follow it.

adrian

|

|

|

Fred W B

|

| posted on 9/10/07 at 06:46 PM |

|

|

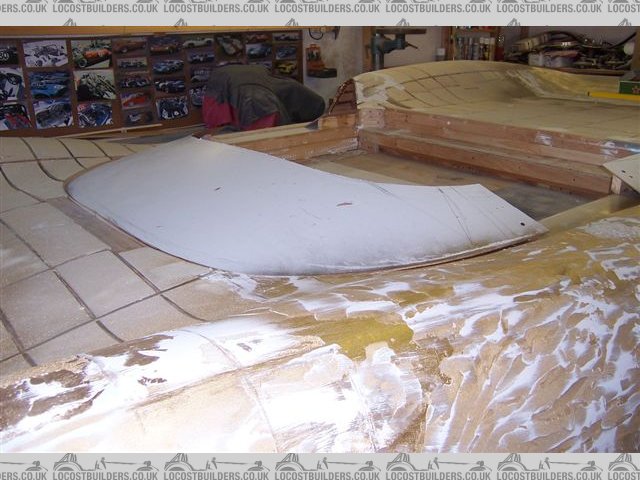

So the tail used to look like this

[img][/img]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 9/10/07 at 06:48 PM |

|

|

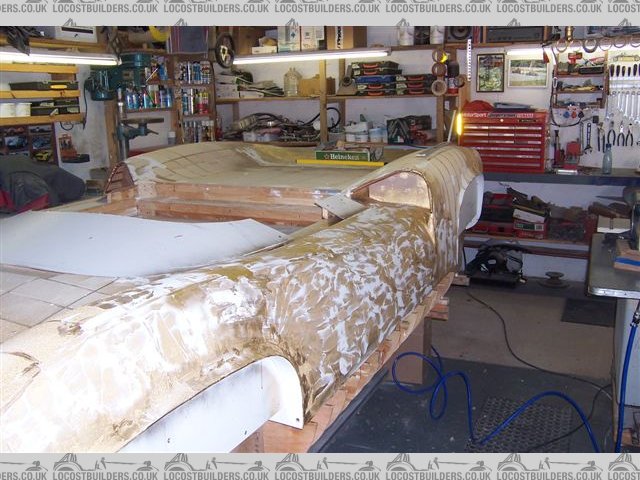

Now it looks like this

[img][/img]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 9/10/07 at 06:57 PM |

|

|

The rear transom panel turned into a real mission

buck 47

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

sgraber

|

| posted on 9/10/07 at 06:59 PM |

|

|

WOW. again - WOW.

Lovin it.

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

Fred W B

|

| posted on 9/10/07 at 07:00 PM |

|

|

But it's now pretty much done, just a few holes to fill and edges to straighten

Note the foam dust lying like snow on the floor along the wall. I blow it away with an airline, it's easier than sweeping up all the time.

Cheers

Fred W B

buck 48 003

[Edited on 9/10/07 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 9/10/07 at 07:01 PM |

|

|

Thanks Steve, you got in just as I was posting the last picture

Cheers

Fred W B

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Delinquent

|

| posted on 9/10/07 at 09:47 PM |

|

|

Have to say Fred, Hats off to you, really no way I could cope with all that manual input, would drive me barmy!

|

|

|

gttman

|

| posted on 10/10/07 at 12:57 PM |

|

|

quote:

Originally posted by Delinquent

Have to say Fred, Hats off to you, really no way I could cope with all that manual input, would drive me barmy!

But doing it in CAD would drive me barmy.

Andygtt

Please redefine your limits

|

|

|

Delinquent

|

| posted on 10/10/07 at 01:01 PM |

|

|

quote:

Originally posted by gttman

quote:

Originally posted by Delinquent

Have to say Fred, Hats off to you, really no way I could cope with all that manual input, would drive me barmy!

But doing it in CAD would drive me barmy.

well yes, that's true as well - with CAD though, a mistake means usually tweaking a few spline co-ordinates and examining the difference,

it's the fact Fred's taken the entire back end off again and re-sculpted it - would be heartbreaking having put so much effort in the

first time!

|

|

|

gttman

|

| posted on 10/10/07 at 07:00 PM |

|

|

quote:

Originally posted by Delinquent

quote:

Originally posted by gttman

quote:

Originally posted by Delinquent

Have to say Fred, Hats off to you, really no way I could cope with all that manual input, would drive me barmy!

But doing it in CAD would drive me barmy.

well yes, that's true as well - with CAD though, a mistake means usually tweaking a few spline co-ordinates and examining the difference,

it's the fact Fred's taken the entire back end off again and re-sculpted it - would be heartbreaking having put so much effort in the

first time!

yep pretty much what I do..... but by doing it in the flesh we can also see the change in the flesh.

Also the satisfaction when you have put it right is quite nice.... I almost forget the pain of doing it for the 4th time.

BTW Fred, top job... keep up the good work.

Andygtt

Please redefine your limits

|

|

|

Fred W B

|

| posted on 17/11/07 at 05:45 PM |

|

|

Thanks for the comments guys.

Some more progress to report. I am now happy the rear panel is ready for skinning. All the openings have 1 degree slope returns and the edges are all

radiused.

[img][/img]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 17/11/07 at 05:47 PM |

|

|

Moving to the mid section, I have mocked up a windscreen template in hardboard in order to establish the angle of the windscreen recess.

screen

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 17/11/07 at 05:49 PM |

|

|

Having reworked the LHS, I am now much happier with the blend into the top of the front wheel arch and the profile of the top of the door. Still have

to finish off and do the RHS.

side rework

door mod

sideeeeeeeee

[Edited on 17/11/07 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 17/11/07 at 06:02 PM |

|

|

We have been discussing the merits of CAD verses old fashioned trial and error following the rework I did to shorten the tail. Here we see the other

approach.

Andrew volunteered to do some more work on the nose of the car. This is the refined front view drawing, which was used to generate a tool path to cut

the front 250 mm of the nose on his home made 3 axis CNC router. The part was cut in 3 sections which were glued together.

model fv

nose cut

nose cut 2

[Edited on 17/11/07 by Fred W B]

[Edited on 17/11/07 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 17/11/07 at 06:08 PM |

|

|

And today I glued the nose on. I am now looking forward to adding the remaining foam and blending it in once the glue dries.

Cheers

Fred WB

[img][/img]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

RazMan

|

| posted on 17/11/07 at 06:10 PM |

|

|

That 3D router certainly does a nice job Fred - what material is it working with?

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

Fred W B

|

| posted on 17/11/07 at 06:49 PM |

|

|

Hi Raz.

The material you see there is polyurethane foam, with a density of about 32 kg/m2. That density is not ideal, heavier would be better.

Cheers

Fred W B

[Edited on 17/11/07 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

jrevillug

|

| posted on 17/11/07 at 11:52 PM |

|

|

Stunning work there. Lots of effort- and it shows.

The modified door looks spot on to me.

James

|

|

|