RichardK

|

| posted on 2/7/06 at 06:32 PM |

|

|

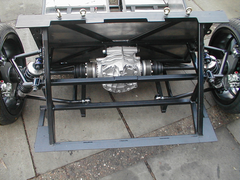

Is it better on top or from behind?

Can anybody see any reason why I can't put my shocker right on top of the hub carrier, I have noticed some cars have it like this and think it

would be better to have the shocker directly above the thing going up and down, but as I am sort of building a half mcsorley and half avon (rear end),

the avon has the shocker mount on the back plate of the hub carrier passing through the upper wishbone.

Picture here

But like a muppet didn't think when making my top rear wishbones didn't think about how wide my shockers where and they won't fit

though the gap in the upper wishbone if I have it like the avon book.

Anybody for see any problems with what I am suggesting as a way round this little predicament.

Your comments are welcome. Especially about the rose joint mushrooms I just did using my ebay bargain lathe for the first time, still got all my

fingers which has gotta be a plus

Regards

Rich

|

|

|

|

|

JoelP

|

| posted on 2/7/06 at 06:37 PM |

|

|

very nice richard.  No problems with what you are suggesting provided it clears the wheels (offset?) and possibly the calipers, but im not sure

where they go exactly. Wheels are a bigger problem i think. Do you have them yet? No problems with what you are suggesting provided it clears the wheels (offset?) and possibly the calipers, but im not sure

where they go exactly. Wheels are a bigger problem i think. Do you have them yet?

An alternative would be to mount them onto a plate on the top bone, though obviously this is not desirable as it would but bending loads onto it.

|

|

|

MikeRJ

|

| posted on 2/7/06 at 07:00 PM |

|

|

As Joel says, nothing wrong with putting the shock mounting there as long as it clears everything. Only thing I would say is that I would be a bit

suspicious of how well those welds have penetrated, bearing in mind this is a safety critical component.

|

|

|

mark chandler

|

| posted on 2/7/06 at 07:11 PM |

|

|

Ideal if you can get them there.

I started going this way but had to abort that plan and planted mine on the lower wish bone, offset to avoid the driveshaft.

The overall height of the top of the shock would have been inches above the wheel arch, your shocks look a decent length so I suspect you will have

the same issue.

Also I have had to cut my top wishbone and introduce a kink and crossbar behind the shock to allow this lump of metal through.

Also although you threaded bushes look very nice flush against the tube like that you would be better off either fish mouthing the ends of the tube to

get a multidirectional weld or drilling a couple of holes further back and plug welding the bush as well (or both).

Regards Mark

[Edited on 2/7/06 by mark chandler]

[Edited on 2/7/06 by mark chandler]

Rescued attachment Rear shock.JPG

|

|

|

RichardK

|

| posted on 2/7/06 at 07:16 PM |

|

|

I know the welding look a bit sh1t but I'm confident it's penetrated ok as I had to file the inside of the wishbones to get my mushroom

down, I will be grinding all of my welding down prior to paint

Cheers

Rich

|

|

|

RichardK

|

| posted on 2/7/06 at 07:18 PM |

|

|

Great minds think alike Mark, I am planning on drilling and plugging as well

|

|

|

JoelP

|

| posted on 2/7/06 at 07:19 PM |

|

|

i hate to advise when my own welding isnt perfect, but IMHO you would be best not grinding it flat, as this can only serve to weaken it. If aesthetics

is important to you, you could just use some filler before you paint it, to smooth it all out.

|

|

|

RichardK

|

| posted on 2/7/06 at 07:27 PM |

|

|

Nah defo won't be getting it flat just taking the lumpy bits off and probably adding more weld to even it all out, hopefully it's ok to

add bits of weld like this and grind back a bit????

|

|

|

JoelP

|

| posted on 2/7/06 at 07:31 PM |

|

|

yeah, you can always retap the thread if you over do it!

|

|

|

t.j.

|

| posted on 3/7/06 at 10:42 AM |

|

|

If it works let me know

i'm planning also at top.

Will it fit underneath the rear arches???

Thats the only main Q.

Also by the increase of the angle you're spring stiffnes has to be different?

|

|

|

Viper

|

| posted on 3/7/06 at 04:41 PM |

|

|

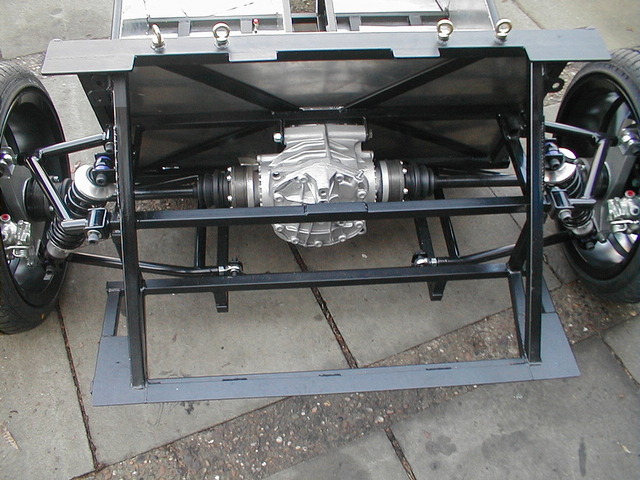

i didn't like the way tiger had done theres so i changed it...

Rear end

|

|

|