t.j.

|

posted on 6/5/06 at 07:27 PM posted on 6/5/06 at 07:27 PM |

|

|

engine mounts

Hi,

Is it stupid to use the sierra engine-rubber mountings incl the standard engine-brackets?

They wil be fitted then on the out-side rail. Where to diagonals come together in a V.

I've estimated that the rubber has an min. height of 70 mm (under max. pressure) and 85 mm unladen.

So tell me, any one?

Ps. i'm using the dohc pre 1993. (yes.. i know)

|

|

|

|

|

britishtrident

|

| posted on 6/5/06 at 08:07 PM |

|

|

Series 3 Land-Rover engine rubber mount are one of the favoured choices -- a good bit stiffer than Sierra.

Another alternative is Fiesta gearbox mounts.

Both are similar in fixing to the Sierra type.

[Edited on 6/5/06 by britishtrident]

|

|

|

Johnmor

|

| posted on 7/5/06 at 08:26 AM |

|

|

Engine mounts

Landrover mounts are a good option and cheap!!!

mm-4x4.com £2.99

|

|

|

britishtrident

|

| posted on 7/5/06 at 10:48 AM |

|

|

quote:

Originally posted by Johnmor

Landrover mounts are a good option and cheap!!!

mm-4x4.com £2.99

I paid a whole 8 squid for mine ---- ;-0

|

|

|

robertst

|

| posted on 7/5/06 at 06:14 PM |

|

|

i was thinking about using the rubber mounts from my sierra too.

the brackets are a whole different story IMO. aren't they too wide for the locost?

Tom

|

|

|

Mark Allanson

|

| posted on 7/5/06 at 08:36 PM |

|

|

The sierra mounts are slow sloppy, I doubt you could keep your engine in the same county let alone in your engine bay, you will end up with alternator

shaped dents in the RH ally sides.

The landy mounts are a proven item, and too cheap not to use.

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

t.j.

|

posted on 9/5/06 at 06:30 PM posted on 9/5/06 at 06:30 PM |

|

|

quote:

Originally posted by robertst

i was thinking about using the rubber mounts from my sierra too.

the brackets are a whole different story IMO. aren't they too wide for the locost?

I thought that Dax also uses the Sierra rubbers.

The mounts are indeed to wide. But if you replace the diagonal 19mm for two which come together at the lower rail it is possible to make there a

bracket.

The advance is that the orginal are in balance with the engine.

I was thinking that if i mount the engine with the bonnet "on" top. Then make the brackets without pressure on the rubber.

Then let the engine rest on the rubbers and the enige will be 1,5 cm below the bonnet.

Bad plan?

|

|

|

Peteff

|

| posted on 9/5/06 at 08:21 PM |

|

|

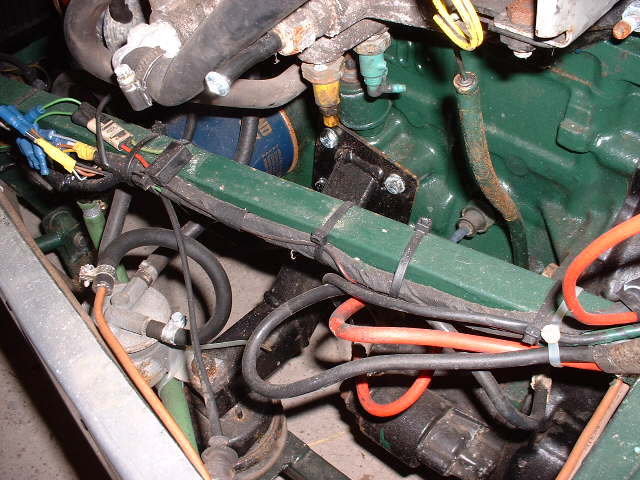

I used them in mine and made my own mounts from 40x3mm rhs as any bigger interferes with the bolts in the plate on the block. They do allow movement

but nothing catches.

Fabricated engine mount

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

dnmalc

|

| posted on 13/5/06 at 03:21 PM |

|

|

The problem when you use thestandard rubers and mounting arms is that the engine is also to low. I am trying to use these arms but I have had to

machine us some bobins approx 70mm high so that the engine is sufficiently high in the chasis to give the correct groud clearance. However given all

the recomendations on using mark 3 landrover this may all have to change.

|

|

|

dnmalc

|

| posted on 13/5/06 at 03:21 PM |

|

|

The problem when you use thestandard rubers and mounting arms is that the engine is also to low. I am trying to use these arms but I have had to

machine us some bobins approx 70mm high so that the engine is sufficiently high in the chasis to give the correct groud clearance. However given all

the recomendations on using mark 3 landrover this may all have to change.

|

|

|

DIY Si

|

| posted on 13/5/06 at 03:28 PM |

|

|

Are you chopping the sump? My engine's sat on home made mounts using the sierra (?) mounts that look like big exhaust bobbins. My engine

currently sits level with the bottom of the chassis, but I'll chop the sump by 1" to allow clearance for a floor. It could probably go a

little lower, but could cause issues with the exhaust manifold.

|

|

|

907

|

| posted on 13/5/06 at 04:05 PM |

|

|

Engine mounts

This might be of no use whatsoever, but I mounted my Lotus on Metro rubbers.

Bent a bit of box with a plate on either end.

Simple looks better IMHO.

hth

Paul G

Rescued attachment Metro-Engine-mount-s.jpg

|

|

|

DIY Si

|

| posted on 13/5/06 at 04:12 PM |

|

|

This is my trial attempt. Going to build another with better elding and thicker (4mm) plates.

Rescued attachment engine mount1.jpg

|

|

|

907

|

| posted on 13/5/06 at 04:19 PM |

|

|

Hi DIY Si.

Is the bolt in your rubber central?

The Metro one is off centre so there is no need for the access cutout in the tube.

Paul G

|

|

|

DIY Si

|

| posted on 13/5/06 at 04:22 PM |

|

|

Yup, cental on both sides. Using them because I recieved a pair with the engine. And don't have a pipe bender handy. Although your's do

look very nice. Although your's do

look very nice.

|

|

|

907

|

| posted on 13/5/06 at 04:31 PM |

|

|

Don't think you would need to bend.

My engine lays at 45 deg so the other side is like yours, straight.

Paul G

|

|

|

DIY Si

|

| posted on 13/5/06 at 04:34 PM |

|

|

What would you suggest as being the best/strongest way of doing this then? The tube I'm using is 38mm x 2(.5?) mm cds. purely because I've

got some offcuts lying about handy. And the two sierra mounts. Would it be worth getting some metro mounts and using some different tude/box?

oh, the engine is an 1800 cvh so reasonably heavy.

[Edited on 13/5/06 by DIY Si]

|

|

|

907

|

| posted on 13/5/06 at 04:40 PM |

|

|

Just doing a pic of other side. back in a min. And 38 x 2 sounds fine.

Paul G

|

|

|

907

|

| posted on 13/5/06 at 04:50 PM |

|

|

This is the n/s mount.

It's made from 25 x 25 x 2.5 thick box.

Paul G

Rescued attachment engine-mount-ns.jpg

|

|

|

DIY Si

|

| posted on 13/5/06 at 04:52 PM |

|

|

That's basically what I want mine to look like. Do you think that having the cutout for the bolt is a problem at all? Or would it be better to

redesign slightly?

|

|

|

907

|

| posted on 13/5/06 at 05:07 PM |

|

|

If you want to make it with a cut out that's fine.

I would keep it as small as possible though.

Only needs to be big enough to access the nut with a socket.

Like you say, top plate needs to be thicker.

I tend to use what I've got.

I went to the factors and asked them what mounts they had in stock, hence I used Metro.

Good luck

Paul G

|

|

|

DIY Si

|

| posted on 13/5/06 at 05:11 PM |

|

|

Cheers. Always good to have ideas seconded. That first one was to see what problems I'd encounter, such as making the hole way too big.

Misjudged the shape completely. Any other hints/tips you know of?

|

|

|

907

|

| posted on 13/5/06 at 05:25 PM |

|

|

Best tip I can give you is never be afraid to ask.

I'm a welder by trade, been making stuff for 30 years, but there are aspects of car building I know nothing about.

Trev D has helped me with bodywork.

David Jenkins is making some electrical bits for me.

Couldn't build my car without other peoples help.

I help someone, someone helps me. It's what this site is all about.

atb

Paul G

|

|

|

dnmalc

|

| posted on 13/5/06 at 06:06 PM |

|

|

Hi DSI

Looking at the photo it would appear that with an un modified sump you seem to have little protruding below the bottom rail if this is the case you

may find that the engine is to high and sits above the limne of the nose cone and scuttle

in these first images you can see what happens with standard sierra mounts

[img]C ocuments and Settingsderek 1My Document[/img] ocuments and Settingsderek 1My Document[/img]

[img]http://C ocuments and Settingsderek 1My DocumentsMy PicturesEngine 1st installationwith sierra mounts[/img] ocuments and Settingsderek 1My DocumentsMy PicturesEngine 1st installationwith sierra mounts[/img]

[img]C ocuments and Settingsderek 1My DocumentsMy PicturesEngine 1st installationwith sierra mounts[/img] ocuments and Settingsderek 1My DocumentsMy PicturesEngine 1st installationwith sierra mounts[/img]

and in the following you can see what hapens with the tiger mountings

[img]http://C ocuments and Settingsderek 1My DocumentsMy PicturesEngine 1st installationwith tiger mounts[/img] ocuments and Settingsderek 1My DocumentsMy PicturesEngine 1st installationwith tiger mounts[/img]

|

|

|

dnmalc

|

| posted on 13/5/06 at 06:08 PM |

|

|

sod it photo did not go in, can somebody remind me how to get the URL I know is something to do with right clicking on the address in the properties

window

|

|

|