Avoneer

|

| posted on 5/2/06 at 11:44 PM |

|

|

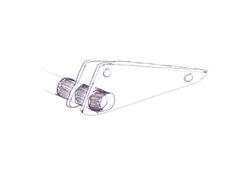

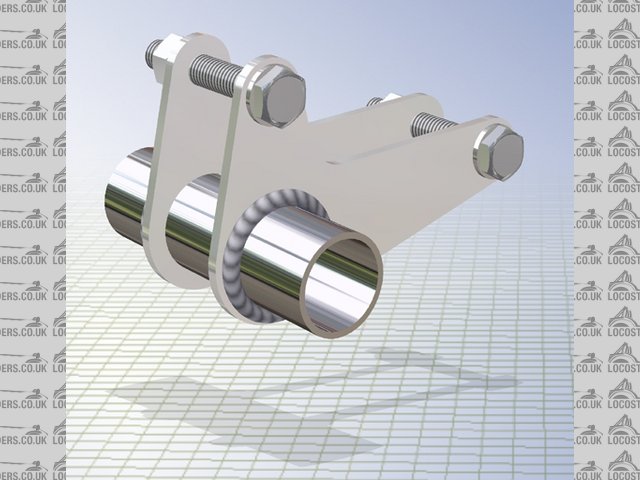

Paddle Shift Top Rocker

Any thoughts on the design/shape for my top rocker for my rod paddle shift?

I will be using two pieces of 3mm ali plate with the rods attached via 8mm rose joints which will be sandwiched between the two plates at the top

point and the far point.

A large tube will be welded to the bottom pivot point and will contain a nylon bush and crush tube and will be bolted to two vertical lugs on the top

chassis rail above the pedals.

Hope that all makes sense.

Pat...

Rescued attachment sketch.jpg

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

|

|

Avoneer

|

| posted on 5/2/06 at 11:46 PM |

|

|

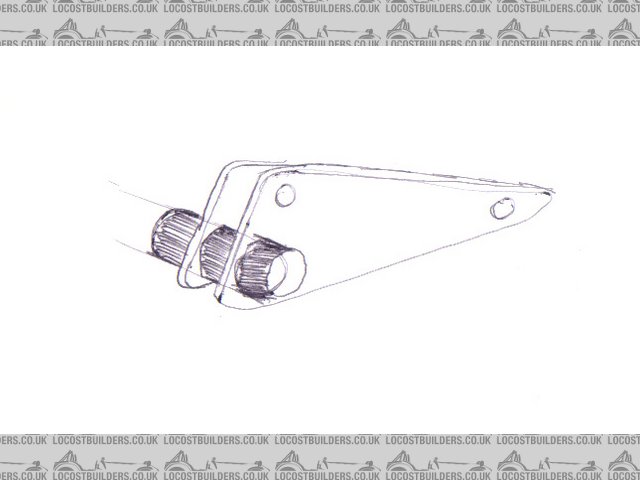

These are my two proposals for the plates:

Rescued attachment bell crank.jpg

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Triton

|

| posted on 5/2/06 at 11:47 PM |

|

|

Bottom one Pat

My Daughter has taken over production of the damn fine Triton race seats and her contact email is emmatrs@live.co.uk.

www.tritonraceseats.com

www.hairyhedgehog.com

|

|

|

Avoneer

|

| posted on 6/2/06 at 12:01 AM |

|

|

Does the top one look a bit phalic?

Pat

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

OX

|

| posted on 6/2/06 at 12:23 AM |

|

|

i'd use the top one just becouse it looks easier to make and doesnt have to be that strong .the gear change is so light you can do it with one

finger

|

|

|

carlgeldard

|

| posted on 6/2/06 at 08:09 AM |

|

|

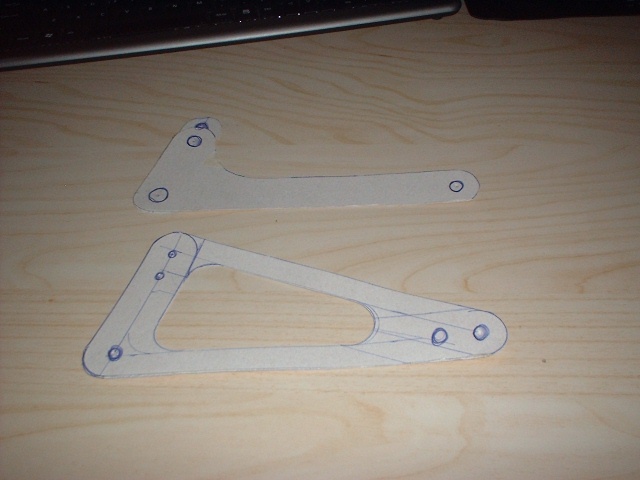

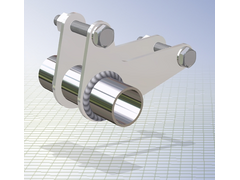

Is this what you mean Pat.

Pats Gear Linkage

Carl

[Edited on 6/2/06 by carlgeldard]

|

|

|

Kissy

|

| posted on 6/2/06 at 10:59 AM |

|

|

If the top left hole is the input side (from driver) then it all looks a bit high-geared. I would expect the distances from the centres to be roughly

equidistant; unless you are getting very little travel from the drivers end. Also 8mm rose joints are a bit ott. 6mm would be better (because you

are clamping between two plates, as I did, you will not get any bending issues, and the rods are in direct tension-compression). I used 5mm joints,

but only because that's what I had in my box of bits!

|

|

|

zxrlocost

|

| posted on 6/2/06 at 11:28 AM |

|

|

agree 6mm

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

Avoneer

|

| posted on 6/2/06 at 12:15 PM |

|

|

Yep - distances are right as the paddle shift has very little movement and is not equal to the distance the splined lever from the gearbox has to move

which is a lot greater - almost 4 times as much.

8mm threaded rod seemed better to me and I already have the rose joints. 6mm rod tended to "flex" when I tried it.

I like it nice and firm

Posh pic Carl - Have you no work to do?

Think the bottom one looks best and goes with the design of the car better.

Ox - mine needs a hard pull - no way could you do it with one finger - but I think this is all to do with the minimal throw my paddles have - unless

I've got it all completely wrong.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

zxrlocost

|

| posted on 6/2/06 at 12:32 PM |

|

|

6mm threaded bar with 6mm bored alloy bar from B&Q

deff doesnt flex then

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

carlgeldard

|

| posted on 6/2/06 at 12:47 PM |

|

|

Got to get my post count up somehow.

|

|

|

indykid

|

| posted on 6/2/06 at 05:40 PM |

|

|

yep, the bottom rocker looks far better.

i can't believe we didn't think of something like it yesterday.

as for the threaded rod, i think it wants to be M8, as with the packaging issues, it's meant the top run's not perpendicular to the

levers in any plane. it does make even m8 threaded rod flex a fair bit. the bell crank is so uneven as the gear box end selector lever is pretty long

to get it around the chassis tube that supports the cradle, that and there's about 3/8" travel tops in the paddles either way so it needs

quite a high ratio to get gears selected positively.

it feels 'right' anyway.

tom

|

|

|

Avoneer

|

| posted on 6/2/06 at 06:12 PM |

|

|

Yep - thanks for all your help Tom.

Extended each arm by 1 hole and the paddle is now really light, but still very positive.

Nearly cracked it.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

tks

|

| posted on 6/2/06 at 09:19 PM |

|

|

wy would you use 2 plates?

3mmplate, or even 2mm take 2,5mm..

and bend an 5mm high wall traight up..

(flange)

on one side..

then it should be rock solid for a manual instrument...

it isn't an brake pedal..

The above comments are always meant to be from the above persons perspective.

|

|

|

Avoneer

|

| posted on 6/2/06 at 09:36 PM |

|

|

I think it would look nice with two plates and would not twist like I think a T section would.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|