02GF74

|

posted on 7/9/06 at 08:05 AM posted on 7/9/06 at 08:05 AM |

|

|

Disputing an SVA failure

Well this should please Mr. Hammerhead as clearly I am confoming to his "argumentitive" desctription of me.

One of my fails was that the mounting point of the harness is too low.

I looked in the SVA manual and did some measurements using a block of very similar shape and placed on the seat as described in annex 4 to find the

seat belt mounting is about 500 mm.

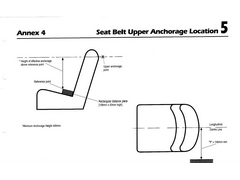

From the manual:

mounting

annex4

Unlesss I am reading the wrong part or misunderstanding it, my inital rough measurements show are that I am well within the specified criteria.

I am using the horizontal plane of the traingular piece through which the seat belt runs as the mounting point.

So what do I do?

Should I write to the SVA place explaining this and get conformation that I have measured correctly so that I can show their response at the

restest?

Basically I don't want to be wasting my time fixzing stuff that is not wrong nor be in a position at the restest where I have misunderesttod the

manual thus not rectified the problem.

[Edited on 7/9/06 by 02GF74]

|

|

|

|

|

Howlor

|

| posted on 7/9/06 at 08:17 AM |

|

|

Do you have any pics of the top mounts, seat and the way you are measuring.

Steve

|

|

|

iank

|

| posted on 7/9/06 at 08:26 AM |

|

|

I'd phone the tester and query it politely as a first step. He will be able to explain his thinking behind failing it.

If he can't answer based on facts in the manual then you can start the official compaints process using his comments against him if

appropriate.

But like many of these things it often ends up being cheaper and quicker to bite your tongue 'fix' the problem with the spacers he

suggested and remove them later.

If you win on that point using 'agressive arguing'  you can guarantee there will be two testers at your retest picking holes in

everything to the letter, including stuff they'd previously checked. Many of which they would have ignored otherwise. you can guarantee there will be two testers at your retest picking holes in

everything to the letter, including stuff they'd previously checked. Many of which they would have ignored otherwise.

At least that's my experience of the way human nature often works.

|

|

|

02GF74

|

| posted on 7/9/06 at 09:18 AM |

|

|

quote:

Originally posted by Howlor

Do you have any pics of the top mounts, seat and the way you are measuring.

Steve

seat belt mounts

re: how I am measuring? Is that a trick question?

if you look in annexe 4, the seat in the diagram is my driver's seat. I place the block (a pate box that is damn close to the size of the

rectangular piece) on the seat base in the centre so that the back of the box rests against the back rest.

Now the vertical line with an arrow at each end is my measuing tape from B&Q that touches the edge of the box as shown and the dotted horisontal

line is my steel meter rule held horizontally to the mounts.

I use my eye to see at which point on the measuring tape the steel rule touches, that is the height I am measuring.

I didn't use a spirit level but it is obvious to me I have a fair few mm before I am getting really close to the limit.

ahhh, fixed so picture pops up.

[Edited on 7/9/06 by 02GF74]

|

|

|

whitestu

|

| posted on 7/9/06 at 09:25 AM |

|

|

I'm using Cobra seats and mine measures about 480 on the 'height of effective anchorage above reference point'.

I measured in a similar way to you using a block and two long rulers.

I was assuming mine would be OK.

If I were you I would want a clear explanation of why you failed.

Try asking the SVA guy how high the spacers he suggested have to be and if he quotes the above rule then politley suggest that you already exceed the

requirement.

Stu

|

|

|

02GF74

|

| posted on 7/9/06 at 09:25 AM |

|

|

quote:

Originally posted by iank

I'd phone the tester and query it politely as a first step. He will be able to explain his thinking behind failing it.

If he can't answer based on facts in the manual then you can start the official compaints process using his comments against him if

appropriate.

But like many of these things it often ends up being cheaper and quicker to bite your tongue 'fix' the problem with the spacers he

suggested and remove them later.

If you win on that point using 'agressive arguing'  you can guarantee there will be two testers at your retest picking holes in

everything to the letter, including stuff they'd previously checked. Many of which they would have ignored otherwise. you can guarantee there will be two testers at your retest picking holes in

everything to the letter, including stuff they'd previously checked. Many of which they would have ignored otherwise.

At least that's my experience of the way human nature often works.

I don't seek to start a war over this  just confirm firstly with the SVA that I have interpreted the manual correctly and have measured

according to the manual. just confirm firstly with the SVA that I have interpreted the manual correctly and have measured

according to the manual.

Then mention that from my results, I am questioning the SVA failure so that at the retest I don't have to start disputing the manual, measurment

etc as it is pretty clear cut to me at the moment that the mounts are correct.

I see what you're saying about the restest going over stuff that previoulsy passed but then surely there is an official complaint procedure

where by someone can to query why stuff that was passed previoulsy now fails although it would be hard to prove that it was not altered in the

meantime. I have no intention of going there but surely fitting spacers on longer bolts is making the mounts more dangerous since there is going to

be more moment on the threaded part?

|

|

|

02GF74

|

| posted on 7/9/06 at 09:30 AM |

|

|

quote:

Originally posted by whitestu

Try asking the SVA guy .....

you all say this like it is easy to speak to anyone at VOSA in LB, trust me it is not

I did ask about this but this was right at the end when the tester was going over the sheet; he said it was marginal but wasn't interested in

showing me & since I did not measure (me bad  ) I wasn't despite what Hammerhead may say, going to start a dispute. ) I wasn't despite what Hammerhead may say, going to start a dispute.

I feel a letter with info. likeI have put in this post would be the best way to get an answer that I can then use at the restst.

|

|

|

andyharding

|

| posted on 7/9/06 at 09:35 AM |

|

|

If you're sure they've made a mistake why not call them and say you took your car to a kit car company for them to carry out the works

req'd to pass and they say you are already within the correct limits for the seat belts will they double check... Then you don't look like

a smart arse.

Are you a Mac user or a retard?

|

|

|

Hammerhead

|

| posted on 7/9/06 at 09:38 AM |

|

|

"Well this should please Mr. Hammerhead as clearly I am confoming to his "argumentitive" desctription of me."

GET OVER IT!

|

|

|

iank

|

| posted on 7/9/06 at 09:53 AM |

|

|

Plenty of posts on here from people who have phoned the tester/local SVA center to ask questions, some even on first name terms. Sorry to hear LB

aren't playing the game.

As for 're-testing' a second tester could 'point out something of concern' and as you say proving it hadn't been changed

is difficult. The wording gives them plenty of discression if they want to get all jobsworth.

p.s. Sorry if I sounded like I thought you wanted to start a war, to be honest I think you have good grounds for a challenge if you want to go that

way, seen too many people spend more time and energy winning on a point of principle than it's really worth though.

Don't they have some kind of jig for testing? Sounds to me like he dropped the tape measure down to the highest point on the squab, rather than

the 'official' diagram.

|

|

|

StevieB

|

| posted on 7/9/06 at 10:06 AM |

|

|

Having never been to SVA before, would I be right in assuming that any fails can be explained by the tester so you know what to do for re-test?

Surely it would be easiest to find out what the tester will accept as a fix.

|

|

|

02GF74

|

| posted on 7/9/06 at 10:09 AM |

|

|

quote:

Originally posted by Hammerhead

"Well this should please Mr. Hammerhead as clearly I am confoming to his "argumentitive" desctription of me."

GET OVER IT!

Why should I? You can say what you want about whoever you want yet one I post something that you don't appear to like, all of a sudden I am the

one who should get over it?

I wasn't the one to start putting labels on people, judging them nor making complaints about their posts.

[Edited on 7/9/06 by 02GF74]

|

|

|

02GF74

|

| posted on 7/9/06 at 10:13 AM |

|

|

quote:

Originally posted by iank

Don't they have some kind of jig for testing? Sounds to me like he dropped the tape measure down to the highest point on the squab, rather than

the 'official' diagram.

TBH I missed that bit.

Seems I give phoning another go to get an explanation for the measurement then take it from there.

|

|

|

whitestu

|

| posted on 7/9/06 at 10:21 AM |

|

|

Good luck!

I think I'll raise mine a bit with some washers prior to the test to make it a bit less marginal

|

|

|

johnemms

|

| posted on 7/9/06 at 11:26 AM |

|

|

Can you remove the bottom of the seat and put a bit of padding on the floor

I plan to do that for 100% clearance pass.....

|

|

|

Hellfire

|

| posted on 7/9/06 at 12:02 PM |

|

|

Personally, I'd leave it be (if you're sure it's OK) and go for the SVA re-test armed with the manual. He may have made a genuine

mistake when he failed it the first time. If he fails it on the re-test, get the manual out and go through the method with him.

There's no point disputing or even discussing it with the tester IMO. I doubt he'd change his mind and even if he did, you've still

got to go for a re-test on the other stuff.

Phil

[Edited on 7-9-06 by Hellfire]

|

|

|

shortie

|

| posted on 7/9/06 at 12:32 PM |

|

|

I agree with Hellfire, these guys do make mistakes and are human, no reason why you can't have a discussion about why it has failed if it fails

again at re-test.

Might be alot easier though to just chuck in a couple of small spacers for the retest, should take all of 5 mins and then no problems.

Rich.

|

|

|

02GF74

|

| posted on 7/9/06 at 12:54 PM |

|

|

quote:

Originally posted by johnemms

Can you remove the bottom of the seat and put a bit of padding on the floor

I plan to do that for 100% clearance pass.....

the SVA man gave suggestions about how to fix it and he said that removal of the cushion is not acceptable, others have tired but were failed -

ofcrouse this is one of those areas that may depend on the tester.

|

|

|

DarrenW

|

| posted on 8/9/06 at 09:49 AM |

|

|

My car was tested with fibreglass seats and no cushions. Is it an option to borrow some seats for the retest?

With seats with harness holes you also have to be very careful that the harnesses dont push down on the bottom of the seat in a crash situation

otherwise they are deemed to be structural and have to have approvals etc.

Sounds to me the easiest way is to modify the mounts to what he suggested. 2 reasons for this;

1. cos this is what he suggested and therefore should pass (is it hard to do?),

2. It proves you arent really argumentative, just enthusiastic and he might then not go into more detail about other points.

Bear in mind he is well within his rights to put the car thro a full retest rather than just the fail points so keep on the right side of him. My

tester was extremely strict but at least he did spend time to discuss possible fixes. I talked to him in the manner to which he had become acostomed

to and this worked for me. All discussions were purely technical / factual and the retest was a breeze. At the end of the day they want you to drive a

car that is safe and enjoy it for many years to come. Believe it or not they want to pass you, it is better for them to fill their diary up with full

paying first time tests than £30 retests.

If he has already labelled you as argumentative then id just roll over and do what he says otherwise he can cause you further pain whilst keeping well

within the guidelines (and cost you another £30 plus time off work and stress etc).

Rear harness mounts are easy to get hold of - you might just need to weld in some longer threaded tubes to get the height right once and for all as

per his recommendations.

I cant help thinking that the section of the book you refer to might need to be read in conjunction with another part, ie possibly ref structural

integrity of seats and type approval. My tester spent a lot of time in this area due to using fibreglass seats. He also then checked steering wheel

heights etc.

|

|

|