Dusty

|

| posted on 14/3/08 at 06:35 PM |

|

|

Poor front brakes.

I have an MNR floor mounted pedal box, balance bar running .625 front and .750 rear master cylinders. Pedal leverage 6:1. Rear standard sierra drums,

front standard sierra discs and calipers with greenstuff pads. I have the balance bar skewed to give maximum possible movement for the front

mastercylinder.

The brakes are pants! The pedal is solid and dead. Hardly any give. The rear m/c rod moves about 1/4 inch max and locks the rears. The front m/c rod

moves about 3/4 inch with hard foot pressure but the pads have not even polished off all the rust from the discs. Bleeding is fine, easy flow, no air.

New DOT 4 in there.

It's driving me nuts. I can't lock the wheels no matter how brutal I am with the pedal. Barely good enough for the road and useless on

trackdays. Anyone have any suggestions apart from refit the sierra m/c and servo?

[Edited on 14/3/08 by Dusty]

|

|

|

|

|

mookaloid

|

| posted on 14/3/08 at 07:09 PM |

|

|

sounds like there might be something wrong with the front master cylinder ...

"That thing you're thinking - it wont be that."

|

|

|

britishtrident

|

| posted on 14/3/08 at 07:12 PM |

|

|

From your description. Sounds like the balance bar is screwed the wrong way, the pivot should be screwed towards the front master cylinder, to give

more front brakes.

|

|

|

Dusty

|

| posted on 14/3/08 at 07:29 PM |

|

|

Balance bar is on an adjuster. Functions correctly in moving the pivot bearing in the pedal. Makes virtually no difference adjusted to either side in

the pedal.

|

|

|

se7ensport

|

| posted on 14/3/08 at 07:34 PM |

|

|

the pads need about 50miles to bed in- have you done that yet? it will be longer if the discs are scored from previous usage.

edit: if the rust isn't gone the pads can't be bedded in properly

[Edited on 14/3/08 by se7ensport]

|

|

|

tks

|

| posted on 14/3/08 at 07:45 PM |

|

|

ow this is a bigger issue then that...

i think your frontbrakes are just bad....

are they from a working donor???

how much fluid did you drain from it it to call it bleeded???

i mean its difficult to bleed good when the rears are fully funcional and the front aren't....

can you see the front pads moveing???

are the discs thick enough??

reconditioned parts?? new parts??

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

Paul (Notts)

|

| posted on 14/3/08 at 07:47 PM |

|

|

Just a few thoghts...

1 As said greenstuff pads can take upto 200 miles to bed in according to their own wed site!

2. I was told to set the front push rod about 5mm longer than the rear push rod to allow for the front calipers larger fluid requirement

3 Are you cylinders the right way round -Small at the front sounds wrong BUT I cant remember which way they shouid be.

Paul

|

|

|

saigonij

|

| posted on 14/3/08 at 08:07 PM |

|

|

Small at the front is correct. This is commonly miss-understood.

Smaller bore to the front as it generates more pressure ( think woman in high heels standing on your stmoach !!!). Pressure is what you want.

anyway, back to the main point...

I had green stuff pads in my capri, ( which had cossie discs and granada scorpio calipers ) and they took a while to heat up - you had to be

constantly on the brakes to keep them warm - then they were fantastic, but cold - they were rubbish.

Even enthusiatic driving was not enough to kepe them warm, and im ont sure a locost kitcar would kepe them warm enough...

i would stick to normal road pads, and even then they will need a beddin in period.

|

|

|

nitram38

|

| posted on 14/3/08 at 08:59 PM |

|

|

Just a little tip regarding your master cylinders as this happened to me.

When I installed my cylinders, the pushrods were level with the pick up point on my pedals.

This means that as you press your pedal the pushrod is not only pushed into the cylinder but is pushed slightly downwards because your pedal travels

in an arc.

This causes the pushrod to push on the cylinder then start taking the pressure off as the rod moves downwards (a bit like a conrod to piston when it

has reached TDC and then goes the other way.)

I had to raise my pushrod to pedal pick up point another 5mm making the puhrod slightly higher at the pedal end.

This means that the pushrod levels off as you press the pedal and keeps the pressure on the cylinder.

[Edited on 14/3/2008 by nitram38]

|

|

|

RazMan

|

| posted on 14/3/08 at 09:28 PM |

|

|

As Nitram says, keep an eye on the angles. The pushrods need to be more or less at their 'bite' point when the bias bar is level, and then

you can try tweaking the front pushrod by lengthening it by a few mm - but not too much or the bias bar will not do it's job.

Also the pushrods need to be pretty much square to the m/c body at the bite point. Also check that the pedal angle is about 90 degrees at the bite

point.

That's a lot of bite points isn't it

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

Dusty

|

| posted on 15/3/08 at 01:03 AM |

|

|

I have been faffing with this problem since last summer. This setup has never worked well yet it should. It is currently at its best yet cannot wipe

the rust off the front discs. The fronts just don't seem to be coming on fully as if the force I apply to the pedal is not fully reaching the

pad.

Pedal does not go past vertical so no decreasing effect due to rotation. After initial fit 9 months ago I have since fitted new front ventilated

discs, reconditioned calipers and the pads have done over a thousand. Angles of pushrods are very near parallel at rest and rise slightly toward the

cylinders. Become horizontal as the pedal is depressed. I have put a litre through today and it is the umpteenth time I have worked on this

problem.

If the front m/c was duff in some way would I be able to bleed the front calipers normally and apparently effectively on pedal pressure. Pedal is

almost without resistance with a front nipple opened and a good flow is seen. Pedal stroke is limited by almost stationary rear master cylinder

rod.

Could it be that .750 is too big for the rears when the fronts are on .625. The balance bar is set at an angle with the front rod long and the rear

short. The bar shifts on full pedal push to the rear clevis pushed back and the front well forward, a sort of seesaw movement. With a smaller rear

cylinder, .700 it may allow more movement of the front push rod?

I would be grateful for any more thoughts. Thanks for the check items so far. I think I have already looked at most of them over the last months

without sorting the effing problem. I have had a couple of heart stopping moments and a trackday off with moderate damage and I can't continue

to drive it like this. Besides it will be faster with better brakes

|

|

|

RazMan

|

| posted on 15/3/08 at 04:59 AM |

|

|

From what you are describing it sounds like the front calipers might be seized so you need to eliminate this and then work back from there.

If you temporarily disconnect the rear pushrod and then apply the brake, can you get full pad force that way? If so then the problem might lie in the

bias bar - have you got a couple of large washers either side of the pushrod clevis as per rally design setup diagram?

here - If not the bias bar could be locking up before enough movement is achieved.

The rear m/c does sound rather large and a 0.7" is probably more like it for balance but the ideal choice depends on your caliper piston sizes.

Having said that it is possible the different stroke lengths might not be allowing enough movement to let the bias bar do its job but replacement

would be a last resort imo.

[Edited on 15-3-08 by RazMan]

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

britishtrident

|

| posted on 15/3/08 at 09:45 AM |

|

|

You have more than one issue.

(1) Your Balance Bar is adjusted so almost all the pedal effort goes to the rear brakes.

Before doing anything else adjust is to the spherical bearing is dead central in the pedal tube. The yokes should have just enough side movement to

allow the balance bar to function (ie pivot) but not enough to prevent the bar locking up if one circuit fails.

(2) To test the front master cylinder remove the outlet pipe from the cylinder and screw a bleed nipple in its place., the bleed the the circuit ---

a couple of pumps should be enough hold the pedal fully down until the nipple is closed

The front master cylinder should now be rock solid if it is you can be 100% sure the master cylinder is ok.

(3) Assuming step (2) is a pass reconnect the pipe to the front brakes and check every single union in the pipe work is fully tight nb this includes

any braided hoses in the system. Then bleed the front circuit. hold the pedal fully down until the nipple is fully closed This

aplies even if you use a pressure bleeder.

[4] If no improvement equip your self with a torch, a bit of paper towel and a brake pipe key and most importantly an assistant. Get the assistant

to put as much pressure on the brakes as possible while you go round every single union drying off and looking with the torch to check for even the

slightest possible leak.

(5) If step 4 dosen't show up anything the next step is to isolate each front wheel in turn --- easy if you have proper OEM

"rubber" brake hoses just clamp them off with a hose nip if you have braided hoses just undo the pipe work at the "T" piece

and screw a bleed nipple in exactly as with the master cylinder test.

[Edited on 15/3/08 by britishtrident]

[Edited on 15/3/08 by britishtrident]

|

|

|

ghostrain

|

| posted on 15/3/08 at 10:59 AM |

|

|

Balance bar adjusting

The problem could be the length of the pushrods at rest-we see this problem often at work(Rally Design)...with a .625 mc at front and .75 at rear

(which would be our suggested sizes) the .625 pushrod has to move considerably further to pressure the front brakes,this can be such that the rear mc

is fully pressurised before you start to pressurise the front brakes.Many people think the balance bar should be at right angles to the pedal at

rest-this is normally not correct,try lengthening the front pushrod as long as possible and shorten the rear pushrod as short as possible-if you then

operate the brake pedal by hand you should be able to visually see the loci of movement straighten the balance bar such that the bar is at right

angles or the front pushrod slightly forwards when the brakes are fully pressurised.

The reason that your brakes are poor at present is you have locked up the balance bar and no matter how much pressure you exert all this pressure is

going to the rear mc,it is possible that the front mc and therefore front calipers are experiencing no pressure at all,hence no front braking.

I hope this is your solution,it would be simple to adjust the pushrods to find out.

By the way this is why you should never have a solid bar across the mc's-believe it or not I have seen balance bars where the balance bar

assembly has welded up.

Your problem is definitely not pads-the EBC Green is a very soft pad-we only sell it for light road use where most of the usage is in traffic-it does

have good anti squeal properties but does fade badly when hot.

Hope this helps.

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

Dusty

|

| posted on 15/3/08 at 12:03 PM |

|

|

Thanks guys. I'm just going outside to the garage for a while. I may be some time.

|

|

|

Schrodinger

|

| posted on 15/3/08 at 07:57 PM |

|

|

Just one thought have you got a pressure operated in line brake light in the front line?

If you have make sure that the sensor is in the angled down of the T as it can hold a small amount of air.

But other than that the others are spot on about finding the problems.

Keith

Aviemore

|

|

|

Dusty

|

| posted on 15/3/08 at 11:42 PM |

|

|

Right so far. Calipers not seized. Bar is set exactly as shown in pic 1 of the link given by Razman and moves to pic 3 on full pressure. No leaks.

Machanical brake light switch and no air in system. Both mastercylinders work normally. Big washers in from the start. Have been using the balance set

full back or full front without realy trying it set in the middle. Setting the bias bar (the pivot bearing) to central position (I drew out the

geometry and compared to either extreme) gives more potential differential movement between the two yokes/clevis's and a longer available stroke

for both rods. This does give a better pedal feel. Not possible to road test as it is raining cats and dogs here in Plymouth but I will find a window

on Sunday.

I am now convinced the bias bar is locking up before the front calipers are full on. I can get a fraction more differential movement in the bias bar

but I suspect I am going to have to get a smaller rear or bigger front m/c to sort it.

Thanks for all the help. Crystalized the thought processes and will lead to the prob getting sorted. Just a pity it's seat out, steering wheel

off, head down the footwell and feet over the rollover bar to do any work on it!

Thanks.

[Edited on 15/3/08 by Dusty]

|

|

|

rusty nuts

|

| posted on 16/3/08 at 09:21 AM |

|

|

If the balance bar is locking up before front brakes are locked then as already suggested adjust front master cylinder push rod to lengthen and

reduce length or rear push rod. You have made no mention of adjusting push rod length in your last post!

|

|

|

NS Dev

|

| posted on 16/3/08 at 10:33 AM |

|

|

......... or move the clevises further apart on the balance bar, you may have them set too tight to the centre tube.

I won't go into how to get them further apart as you obviously put the bar together!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

ghostrain

|

| posted on 16/3/08 at 01:20 PM |

|

|

Dusty....at least 5 contributors have mentioned push rod length including myself but you appear to be ignoring making the front push rod longer and

therefore the rear push rod shorter....am getting a little annoyed that you are ignoring the obvious solution.You may also wish to check that the

balance bar is not locking up on inside of the balance bar tube....I have seen one balance bar assembly that had a big diameter shaft and a small

internal tube diameter( the manufacturer was not an engineer!)...please do not start changing master cylinders the setup diameter you are using is

used by hundreds of kitcars with good balance. ironically if you increased the diameter of the front master cylinder it may improve your braking but

for the wrong reasons....you will decrease the power available to your front brakes but because you are reducing the necessary movement to pressurise

the front master cylinder you may overcome your balance bar lock up problem,but this is completely the wrong approach.

Try putting some plasticene at both ends of your balance bar tube and see if shaft locks out at full pedal movement...you could always open out the

inside of the tube by chamfering the tube ends i.d.

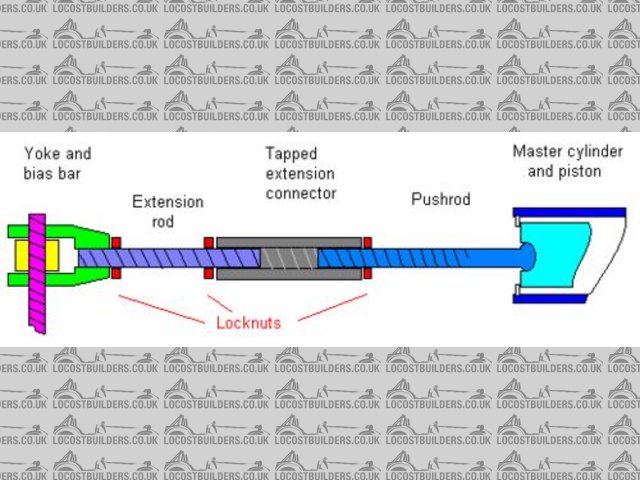

If you have made your push rods too short we do sell extensions at Rally Design (used on the cosworth pedal box) which may save you buying new master

cylinders.

You probably have all the right parts,don't go buying any more new bits until you check whether mechanically you are restricting the movement of

the front master cylinder pushrod.

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

Dusty

|

| posted on 16/3/08 at 01:52 PM |

|

|

Jees guys, don't get so stern. There are a few things I haven't mentioned. I'm well aware that the pushrod lengths have to be

adjusted to give maximum effective length to front and minimum to rear. I would have thought that me saying the pushrods are currently adjusted like

the first pic in the rally design link and move to the position shown in the third pic would show that I am on it. I have also said it's seats

out and head down the footwell. I even printed out three of the answers on page 2 of this thread and took them in the garage with me yesterday.

However I think because of the volumes of the two master cylinders, the volumes of the caliper and rear cylinders I am still going to have to alter

master cylinder size. This is despite consideration of reducing the width of the tube in which the bias bearing runs,(this would allow it to achieve a

greater before and after angle thus increasing differential rod movement) and making a new pushrod extension yesterday when I reached the limit of

adjustment.

I am listening. I have heard. Thanks for the ongoing advice but no need to nag!

(I did discuss this with one of the guys on the rally design stand at one of the shows, Newark I think last year.)

[Edited on 16/3/08 by Dusty]

|

|

|

Dusty

|

| posted on 16/3/08 at 03:41 PM |

|

|

Just been out as it's dry down here today. Feels much better. Beautifully progressive and I can lock the left front. I think the right front may

need more time to bed in but that is just standard brake stuff. Not a problem.

I will hold off on the new mastercylinder till I have more miles under the wheels.

Diagnosis was bias bar locking up. Undoing the bar one turn out of one of the yokes to separate them a couple of mm further and extending the front

pushrod by about an inch (not used all that, probably used an extra 4/10ths) to give greater differential movement has made a lot of difference. Both

discs red hot when I got home after 10 minutes drive.

Once again thanks for all the advice that has led to sorting the problem.

|

|

|

saigonij

|

| posted on 16/3/08 at 03:50 PM |

|

|

is it possible to increase - decrease the length of the pushrods with the pedal box bolted in?

|

|

|

MikeRJ

|

| posted on 16/3/08 at 04:14 PM |

|

|

quote:

Originally posted by Dusty

Just been out as it's dry down here today. Feels much better. Beautifully progressive and I can lock the left front.

Have you ever set the corner weights on the car?

|

|

|

Dusty

|

| posted on 16/3/08 at 06:04 PM |

|

|

Haven't done corner weights ever.

I already have pushrod extensions due to my pedal layout etc so was able to remove the extension and add a longer threaded extension. As in

pic.

Rescued attachment pushrod.jpg

|

|

|