matt.c

|

posted on 9/8/08 at 11:13 AM posted on 9/8/08 at 11:13 AM |

|

|

Sump baffle plate thickness?

1. Going to make a alloy zx9 baffle plate but how thick should it be?

2. Where can i get a piece of alloy sheet the thickness above measuring 12 inches by 12 inches? Ie places like B&Q ect?

3. I need to shortern my pickup. Do you just cut an inch out of the stem and just stick it back together edge to edge or do i have to sleave it in?

Description

Many thanks locosters

|

|

|

|

|

worX

|

| posted on 9/8/08 at 11:26 AM |

|

|

I think you are probably best making it in Stainless Steel...

I think the Ali ones can fracture.

Steve

|

|

|

matt.c

|

| posted on 9/8/08 at 11:35 AM |

|

|

ok steve, what about the other questions?

|

|

|

mistergrumpy

|

| posted on 9/8/08 at 11:44 AM |

|

|

I've used 1mm ally. (I think it may be 0.9mm to be honest) but I haven't shortened the sump, gonna try and get away with it. IRC from

searching other threads yes you just cut as shown and some people have used a collar to help stick the pick up back together.

|

|

|

ChrisGamlin

|

| posted on 12/8/08 at 07:19 PM |

|

|

Hi Matt

As just mentioned in my u2u reply, this is roughly how my uncle used to do them

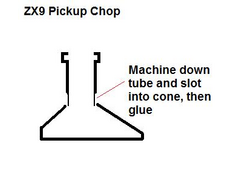

ZX9 Pickup chop

Basically he'd cut the pickup off where it goes from tube to cone, then chopped again further up to get the desired length. He then machined a

shoulder on the tube segment and reamed out the conical bit slightly until the tube segment would just about slide/snap into the conical section. He

then glued them together with superglue I think, or possibly Epoxy resin (Araldite).

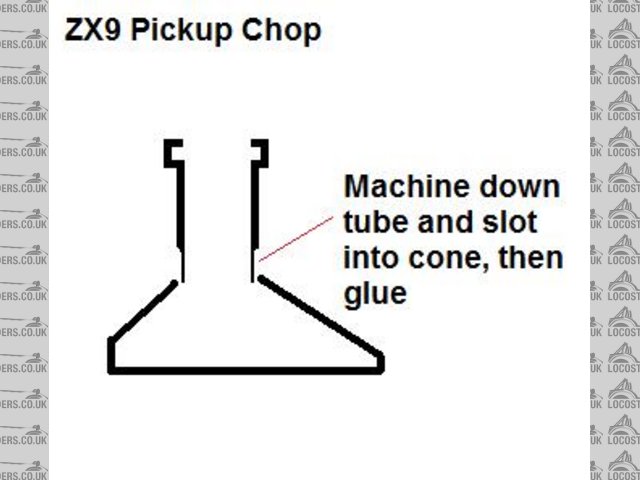

As to the thickness of the baffle plate, this is what happened to my original fireblade baffle:

Blade Baffle fatigue cracked

Im not sure what thickness it was but its the one Westfield / STM / Kit Car Workshop used to supply, I think it was about 1.5mm thick. With that in

mind I'd go as thick as you can get away with, or preferably as others have mentioned use thin stainless steel if poss.

cheers

Chris

|

|

|

matt.c

|

| posted on 12/8/08 at 07:42 PM |

|

|

quote:

Originally posted by ChrisGamlin

Im not sure what thickness it was but its the one Westfield / STM / Kit Car Workshop used to supply, I think it was about 1.5mm thick. With that in

mind I'd go as thick as you can get away with, or preferably as others have mentioned use thin stainless steel if poss.

cheers

Chris

How thin in stainless are you talking about then?

|

|

|

ChrisGamlin

|

| posted on 12/8/08 at 08:44 PM |

|

|

Steel doesn't suffer from fatigue cracking like aluminmum so it only needs to be thick enough to support its own weight really, so 1mm or so at

a guess

|

|

|

matt.c

|

| posted on 12/8/08 at 09:18 PM |

|

|

Thank you chris

|

|

|

simoto

|

| posted on 13/8/08 at 08:05 AM |

|

|

Oh dear thats another piece of rubbish i have bought in my ignorance(baffle as above)

Just cleaned the gasket faces last night.

Thanks for tthe heads up, had an idea due to other posts but not seen one photographed like that!

Being honest i was going to risk it, not now though. Cheers for that

How long was it installed?

striker/blade now complete, thanks to all on this site.

|

|

|

ChrisGamlin

|

| posted on 13/8/08 at 06:31 PM |

|

|

The above was installed for about 3 years, around 20 trackdays and maybe 4-5k road miles, and to be fair Ive not seen another one go quite like that

so its possible that one was a bad batch of metal. If I was fitting another though I'd certainly drop the sump on each oil change to check it

was still intact, but probably would look to get a stronger one to avoid the worry.

|

|

|