hillbillyracer

|

| posted on 28/12/11 at 09:58 PM |

|

|

Anyone got a large throttle body they want shot of?

By large I mean as big as 85mm dia! Made a new heater for the workshop & it burns rather too well, nice & warm in there but I'll never

keep it in logs! The intake hole is the inspection hole of an old compressor tank I've used & is the same area as 85mm dia would be, but

I'm thinking a good bit less would be fine but how big do they go? By the time something is making the power something this large would be

justified for it'd either be on multiple throttles (& be pretty exotic) or extreme modded forced induction stuff & not that common

either.

So failing anyone happening to have an unwanted spare from their blown to bits 1000bhp Skyline anyone any ideas what bonnets I should be lifting in

the scrappy to find something that'll do? Big Jags, BMWs & Mercs I'm thinking.

If I need to use 2 to make it flow well enough by the time I make a simple Tee manifold I may as well just get a big bit of pipe & make a simple

slide to regulate it.

|

|

|

|

|

hillbillyracer

|

| posted on 28/12/11 at 11:15 PM |

|

|

A quick measure & calculate suggests that 70mm dia would make it the same as the old heater which was similar in size & worked well enough.

Anything use a throttle body that big?

Then again the door on this one shuts properly so no air gets in past the sides & the old one was not so good, likely let a good bit in that way

too & this one wont do that, if I block the inlet the fire goes out pretty quickly.

|

|

|

Benzine

|

| posted on 28/12/11 at 11:23 PM |

|

|

I may have a volvo 960 throttle body lying around. Straight six (2.5 or 3.0) but only one throttle body so quite big, i'm guessing somewhere

around the 6-7cm mark. I won't be able to check for at least a couple of days though

Alternatively could you make an intake? Bit of tube, a nut welded in the middle (suspended with metal bar/rod) and a threaded rod attached to a

circular plate with a handle on it. Then a bit of fire rope for a good seal. Screw it in to turn down, unscrew to turn it up. Like this one in a stove

i made (bottom left):

[Edited on 28-12-2011 by Benzine]

|

|

|

hillbillyracer

|

| posted on 28/12/11 at 11:52 PM |

|

|

I may indeed just make something, might not be too far from a scrappy tomorrow so I'll see what's in if I get time.

|

|

|

clairetoo

|

| posted on 29/12/11 at 08:55 AM |

|

|

I've just finished a new log burner for my house - this one is baffled internally and even has a pyrex window in the door - for air control I

just plasma cut some 3mm sheet to make the flaps .

Its now painted black and doing a great job of heating my house

I think you may find that the heat will very quickly destroy a throttle body - and may even melt it

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

hillbillyracer

|

| posted on 30/12/11 at 05:26 PM |

|

|

Trip to the scrappy wasn't going to happen so I had a search about my pile of odds & sods to see what I could do:

A heavy pipe flange with a 75mm hole in the middle & a ring of bolt holes around the outside.

A triangular off cut of 12mm plate wide enough at one end to cover the 75mm hole in the pipe flange & the other end reach one of the bolt holes in

the flange.

An exhaust flange spring from a Peugeot diesel.

A length of 89mm exhaust tube.

Short bit of 89mm tube welded between flange & inlet of heater door, triangular plate drilled at one end to pivot on one of the ring of bolt holes

in the pipe flange & the spring over the bolt forming the hinge of the plate so it stays where it's set & pulls the plate tight to the

flange to make it fairly air tight, job done in about an hour & it works perfectly. Nothing like a pretty as a nice throttle body but job done.

I'd take a piccy to show you but I can't get a good location for the camera. As in I don't know the location of the camera &

it's been missing a couple of days, OOPS!

I doubt whether the heat would have been a problem, there's a baffle directly behind the inlet in the door which means the air has to go down to

the bottom of the door to enter the barrel both to keep the heat back a touch & more importanly prevent any sparks etc being thrown out. With the

heater roaring a way as hot as it gets I can touch the air inlet for a few seconds at a time, mabye wouldn't have been good if there were

plastic bushes on the spindle though.

Liking the burner for your house though Clairetoo, no problems with building regs or the like for making your own burner?

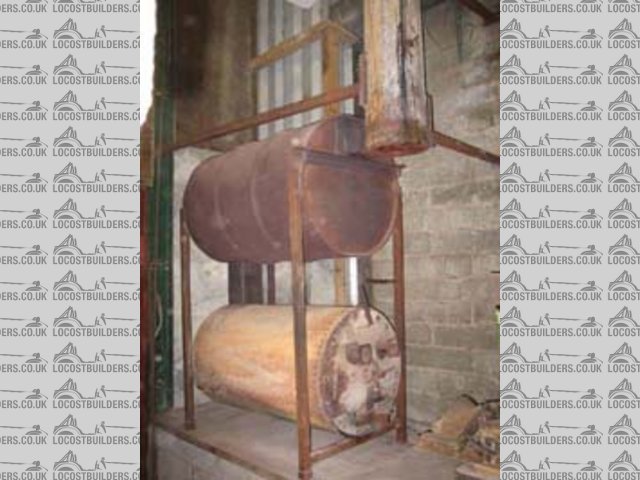

What I've built is just another of what I did before pictured below, though this time I've used an old compressor tank on the bottom &

proper stainless flue pipe with a heat resistant flashing to seal the roof & prevent the rain rusting it out as happened to the old one

workshop heater 1

|

|

|

owelly

|

| posted on 31/12/11 at 01:24 AM |

|

|

If you'd asked, I think I have a couple of 4" iso valves kicking about.

http://www.ppcmag.co.uk

|

|

|

hillbillyracer

|

| posted on 31/12/11 at 09:16 AM |

|

|

Ah well the last heater lasted about 5-6 years but I've made a slightly better job of this one so even if the top barrel rusts out in 7 or so

it'll be easier replaced & the rest should last longer. Could you keep hold of the valves till 2026 when I may need to do it again?

|

|

|