liam.mccaffrey

|

| posted on 26/10/05 at 10:16 PM |

|

|

907 will have made provision for this im sure guys, to make an english wheel you must understand how one works. I don't think it is as it

appears

Build Blog

Build Photo Album

|

|

|

|

|

JoelP

|

| posted on 26/10/05 at 10:29 PM |

|

|

i too wondered which bit moved, but to be honest, you'd need to be real stupid to make it with both wheels fixed   and i assume he knows a

little more about it than me! and i assume he knows a

little more about it than me!

Beware! Bourettes is binfectious.

|

|

|

NS Dev

|

| posted on 26/10/05 at 10:37 PM |

|

|

and his welding is far too bloody neat, git!

|

|

|

907

|

| posted on 26/10/05 at 11:24 PM |

|

|

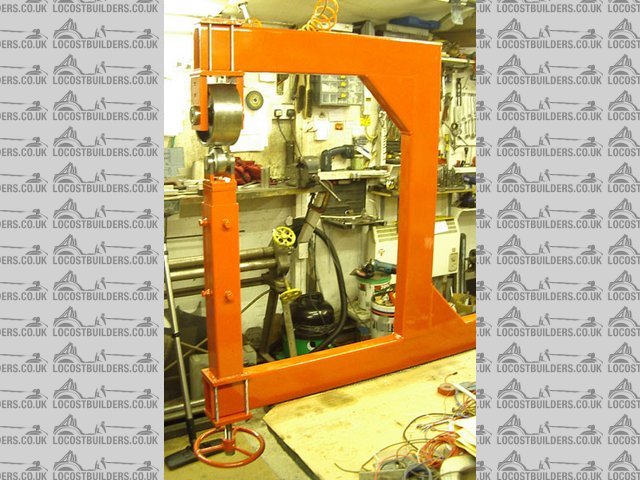

It's the opposite way up to Rorty's,

but then again, since he's in Oz it would be.

The vertical bit is 80 x 80 box. Inside it is a bit of 70 x70 and a thread runs

down the middle with a wheel underneath, (or it will have when it's finished).

The frame is 120 x 60 x 6.

I have no idea how strong it will need to be, but the plan is to have a throat

big enough to make an air scoop in a bonnet.

Any advise welcome.

Paul G

|

|

|

Rorty

|

| posted on 26/10/05 at 11:30 PM |

|

|

I didn't doubt your ability at all having seen some of your fabrication work before.

Does your Ewheel have a kick wheel for adjustment then? Some swear by them and some swear at them when they repeatedly anneal their shins on them.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

907

|

| posted on 26/10/05 at 11:38 PM |

|

|

That's the idea.

Thinking of M18 fine (because I have a tap that size).

Is the finer the better?

Paul G

|

|

|

Rorty

|

| posted on 27/10/05 at 12:03 AM |

|

|

quote:

Originally posted by 907

That's the idea.

Thinking of M18 fine (because I have a tap that size).

Is the finer the better?

Paul G

Yes, although a weaker thread, finer is better, but I'd up the size to at least M22 x 1.5 (or even M24 x 2) especially as it's a kick

wheel and will be subject to greater side loads and the inevitable knocks.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

rusty nuts

|

| posted on 28/10/05 at 05:55 PM |

|

|

Paul, might be able to help with a larger tap. Possibly up to 22mm if it's any help .

|

|

|

907

|

| posted on 28/10/05 at 06:55 PM |

|

|

Is that M22 fine (x1.5)?

If it is, that would be great Melvyn.

I have all the normal metric taps up to 24 and brakes (10x1), fan switch (14x1.25), and the w/bones (18x1).

At £20 ish apiece I grudge buying them just to cut one thread.

Cheers,

Paul G

|

|

|

907

|

| posted on 29/10/05 at 08:21 PM |

|

|

The wheels nearly finished.

Just a few probs to iron out; like get rid of that spanner hanging on the bottom.

AND IT WORKS AND IT WORKS     , well sort of. , well sort of.

Now where did I put those ally offcuts.

Paul G

Rescued attachment e-wheel-8-s.jpg

|

|

|

907

|

| posted on 29/10/05 at 08:31 PM |

|

|

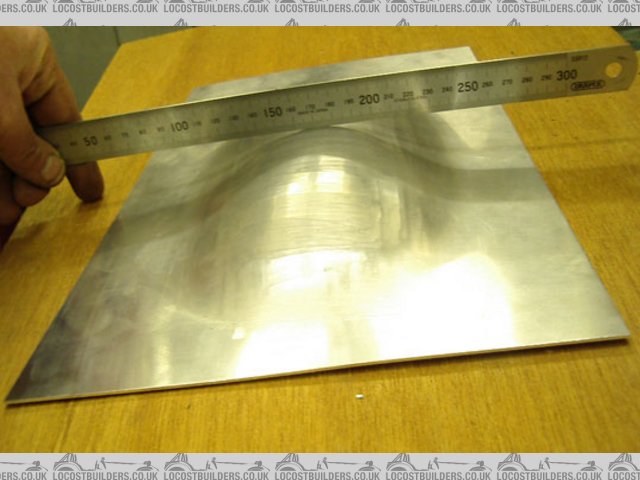

Please be gentle. It's my first go.

WOW, 1000 hours of practice and I should get the hang of this.

and what's more, I'v still got my thumbs.

Pic below is a bonnet bulge for a Fiat 500

Paul G

Rescued attachment bump-s.jpg

|

|

|

Avoneer

|

| posted on 29/10/05 at 09:41 PM |

|

|

And how smooth did it end up?

Looking really good though.

Will there be a spurt of wheel arches like the cans?

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Rorty

|

| posted on 29/10/05 at 09:54 PM |

|

|

quote:

Originally posted by 907

WOW, 1000 hours of practice and I should get the hang of this.

and what's more, I'v still got my thumbs.

Pic below is a bonnet bulge for a Fiat 500

Paul G

Beautiful job Paul. Make sure you polish the hell out of those wheels and anvil as their surface finish is directly related to the finish you'll

get on your work.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

907

|

| posted on 29/10/05 at 11:21 PM |

|

|

quote:

Originally posted by Avoneer

Will there be a spurt of wheel arches like the cans?

Pat...

There certainly will Pat.

The thread will be called...

"Anyone need a Wok?"

As for the finish, I'll have a go with a rag mop and see what it comes up like.

Maybe I should have gone down in smaller stages. I think it's going to be a bit of a learning curve.

The pic below is the best I can do. It's taken about 50 mm from the surface.

Paul G

|

|

|

907

|

| posted on 29/10/05 at 11:23 PM |

|

|

Forgot the ****** pic

Doh

Rescued attachment bump-texture-s.jpg

|

|

|

Gaz 1977

|

| posted on 30/10/05 at 10:06 PM |

|

|

looking good, cant wait to see more results

|

|

|

907

|

| posted on 31/10/05 at 12:15 AM |

|

|

quote:

Originally posted by Gaz 1977

looking good, cant wait to see more results

Fish pond liner. Now there's a project.

Paul G

aka Dad

|

|

|

Gaz 1977

|

| posted on 1/11/05 at 01:46 PM |

|

|

big dent

I cant believe that mother used your head as a former for the ally

|

|

|

Cita

|

| posted on 1/11/05 at 02:12 PM |

|

|

|

|

|

907

|

| posted on 9/11/05 at 08:18 PM |

|

|

I love it when a plan comes together.

First of all, many thanks for all the assistance I'v had with this little project,

especialy Melvyn, (Rusty Nuts) for the loan of the M22f tap, delivered it too.

It's now finished. All I'v got to do now is learn how to use it.

From the pics I'v seen on the net, I'v come to the conclusion that they have

to be painted a realy revolting colour, so mine's "poppy", to match my eyes.

Many thanks everyone,

Paul G

Rescued attachment Its-wheelie-done.jpg

|

|

|

Rorty

|

| posted on 9/11/05 at 08:27 PM |

|

|

Very nice too. Well done. Can I have a set of 18/10 saucepans please?

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

907

|

| posted on 9/11/05 at 08:49 PM |

|

|

quote:

Originally posted by Rorty

Very nice too. Well done. Can I have a set of 18/10 saucepans please?

Would that be a 10 inch, and an 18 inch then?

What do you have in mind..... JAM MAKING?

Paul G

|

|

|

Rorty

|

| posted on 9/11/05 at 09:15 PM |

|

|

18/10 being the stainless material to really test your skills, but since you're offering, I do need a new jam pan. I'm not allowed to make

my marmalade in the copper one anymore as it has been elevated to ornament status!

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

stevebubs

|

| posted on 9/11/05 at 10:24 PM |

|

|

quote:

Originally posted by 907

Good replies chaps, but still want to find someone who has used one.

Anyone know where you can buy "casenite"? ( case hardening powder )

Paul G

They had one at the welding course I attended in Bracknell (was also covering sheet metal work). they had the bodywork guy in showing how to repair

panels etc. he got us to use one of these in turn to start forming the metal for a wheel arch patch.

Quite impressive the way it works - just keep sliding back and forth.

Stephen

PS If you ever watch American hotrod, they use theirs quite frequently for forming chassis rails etc.

[Edited on 15/11/05 by stevebubs]

|

|

|

stevebubs

|

| posted on 9/11/05 at 10:25 PM |

|

|

PS Just scrolled down and seen the finished item - very nice!

|

|

|