daviep

|

| posted on 27/6/06 at 09:44 AM |

|

|

Look what I made!!!

This probably a bit sad but I'm quite pleased with myself.

Went out to fit aluminium pipes for cooling system but ended up making a tool for ridging the ends of the pipe. What do you think of the results? Can

you buy a tool for doing this?

[img][/img]

|

|

|

|

|

ned

|

| posted on 27/6/06 at 09:47 AM |

|

|

looks good, what did you make/how does it work then and where's the diy guide

beware, I've got yellow skin

|

|

|

daviep

|

| posted on 27/6/06 at 09:54 AM |

|

|

It wouldn't be any fun if I told you how I did it straight away! How would everyone else attempt it? All will be revealed once I make version 2

of my tool and take some pictures

|

|

|

nick205

|

| posted on 27/6/06 at 09:59 AM |

|

|

yes you can buy tools to do that, but I'd bet there not cheap for something you wouldn't use too often.

Your results look spot on

I'd like to see how it works too please!

|

|

|

Nisseven

|

| posted on 27/6/06 at 10:09 AM |

|

|

Yep plumbers use them all the time. It has three or four ball bearings with a taper to push them out of the holes in the tool. The taper is threaded

so that you can wind it in and out.

Bruce

|

|

|

Hellfire

|

| posted on 27/6/06 at 10:14 AM |

|

|

quote:

Originally posted by daviep

It wouldn't be any fun if I told you how I did it straight away! How would everyone else attempt it? All will be revealed once I make version 2

of my tool and take some pictures

If you can't play the game... I'll have me ball back!!!

|

|

|

chrsgrain

|

| posted on 27/6/06 at 11:20 AM |

|

|

Would be very interested - go on - tell us how you did it!!

Chris

|

|

|

DaveFJ

|

| posted on 27/6/06 at 11:26 AM |

|

|

like this?

link

a snip at only £399

Dave

"In Support of Help the Heroes" - Always

|

|

|

John Bonnett

|

| posted on 27/6/06 at 01:12 PM |

|

|

Look what I made!!!

The result looks spot-on. I've got to do the same so if I (along with many others) will be delighted to hear and see how you did it. I have a

swaging/beading machine but the tooling is too large for a coolant pipe.

A really good effort, well done!

John

|

|

|

TheGecko

|

| posted on 27/6/06 at 01:41 PM |

|

|

quote:

Originally posted by daviep

It wouldn't be any fun if I told you how I did it straight away! How would everyone else attempt it? All will be revealed once I make version 2

of my tool and take some pictures

How about this? (not my work - found on the web).

Dominic

Cheap bead roller 1

Cheap bead roller 2

Cheap bead roller 3

|

|

|

bob

|

| posted on 27/6/06 at 01:43 PM |

|

|

quote:

Originally posted by daviep

It wouldn't be any fun if I told you how I did it straight away! How would everyone else attempt it? All will be revealed once I make version 2

of my tool and take some pictures

Thats like offering a kid candy and then taking it away

|

|

|

Bluemoon

|

| posted on 27/6/06 at 02:19 PM |

|

|

Indeed, can we see version 1 please.... Don't particulary care about looks etc, just want ideas on a neat way to do this...

Cheers

Dan

|

|

|

BKLOCO

|

| posted on 27/6/06 at 02:24 PM |

|

|

Give me half an hour and I'll take a pic of my home made tool (ooo errr) which will put beads on pipes down to 12mm dia.

Made it ages ago.

Did all my ally and copper coolant pipes with it.

I will lend it out for the price of postage.

PS I used cheap TV aerial mast for large bore tube.

[Edited on 27-6-06 by BKLOCO]

Experience is what you get when you don't get what you want!!!

|

|

|

BKLOCO

|

| posted on 27/6/06 at 02:47 PM |

|

|

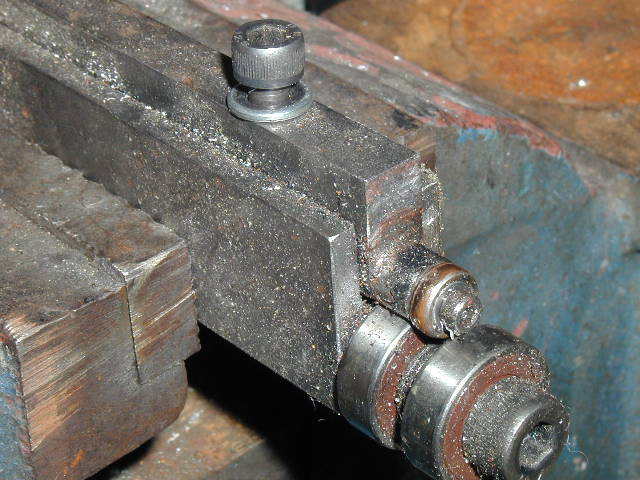

There ya go

bead former in vice

bead former close up

bead former in use

Sorrythis ones out of focus

bead out of focus

This tool works fine in a vice turning the pipe by hand but is much better/faster if you use it in a lathe.

This is a piece of 16mm bore ally tube.

[Edited on 27-6-06 by BKLOCO]

Experience is what you get when you don't get what you want!!!

|

|

|

Confused but excited.

|

| posted on 27/6/06 at 03:05 PM |

|

|

I like TheGeko's designer work station.

[Edited on 27/6/06 by Confused but excited.]

Tell them about the bent treacle edges!

|

|

|

nitram38

|

| posted on 27/6/06 at 04:21 PM |

|

|

NICE TOOL !!!!!!

|

|

|

John Bonnett

|

| posted on 27/6/06 at 04:25 PM |

|

|

Look what I made!!!

Okay, you've got our interest!!

Come on, be a sport and tell us how you did it.

John

|

|

|

daviep

|

| posted on 27/6/06 at 05:12 PM |

|

|

Sorry I had to go and work today so I've not been able to take any pics but I promise I'll take some good pics and post them with a list

of materials at the weekend. What I've made doesn't look anything like ant of those shown and you can use it in-situ.

Didn't mean to tease

|

|

|

BKLOCO

|

| posted on 3/7/06 at 02:54 PM |

|

|

So where is it?????????

Experience is what you get when you don't get what you want!!!

|

|

|

indykid

|

| posted on 5/7/06 at 05:40 PM |

|

|

bump!

is your camera broken?

tom

|

|

|

MikeRJ

|

| posted on 7/7/06 at 08:42 PM |

|

|

I've seen one made from a pair of mole grips with modified jaws, i.e. a groove in one side and a bump in the other with the jaws rounded to fit

the pipe profile.

|

|

|