smudger748s

|

| posted on 22/1/08 at 07:35 PM |

|

|

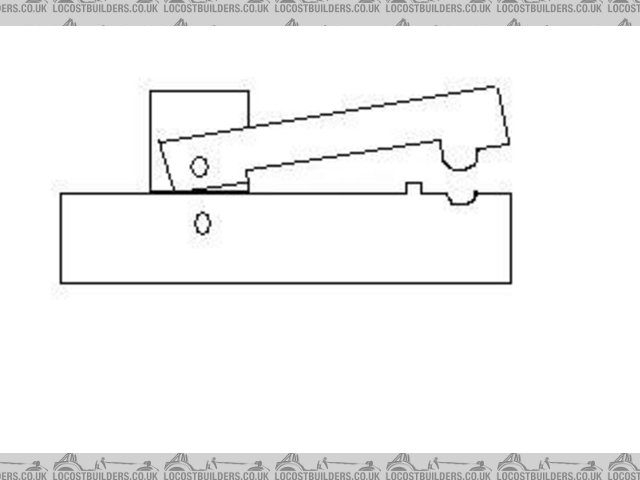

bead maker

2 backing wheels off a grinder drilled to 16mm and a 10mm allen key

will do stainless,ally,mild steel

[Edited on 22/1/08 by smudger748s]

Rescued attachment IMG_0027.JPG

|

|

|

|

|

StevieB

|

| posted on 22/1/08 at 08:35 PM |

|

|

That's a smart little design.

I may undertake some blatent plagerism at some point!

[Edited on 22/1/08 by StevieB]

|

|

|

NS Dev

|

| posted on 22/1/08 at 09:01 PM |

|

|

heath robinson at his best!! Effective though!!

Some bearings for the allen key bit would finish the job off nicely

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

thomas4age

|

| posted on 22/1/08 at 09:52 PM |

|

|

and you use this to ?bead? what...?

how do you opperate it?

first time I had a language problem here I think, sorry cloggy over here.

grtz Thomas

[Edited on 22/1/08 by thomas4age]

If Lucas made guns, Wars wouldn't start either.

|

|

|

blueshift

|

| posted on 22/1/08 at 10:20 PM |

|

|

I get it.. I'm guessing a bit of grease helps that one along! looks painful..

|

|

|

smudger748s

|

| posted on 22/1/08 at 10:27 PM |

|

|

you offer the tube you want to put a bead on (eg coolant pipe ally,stainless,copper or mild steel)onto the ground allen key and tighten the adjuster

nut a bit at a time putting pressure on the two wheels that rotate whilst turning

the ratchet 360 degrees until a uniform bead is produced.

cheaper than paying £3 an end or £250 for a manufactured item

quite a simple tool to use

and i,m sure somebody with a lathe could knock one up incorporating bearings which would make it as good as a pro one

regards Smudger

|

|

|

NS Dev

|

| posted on 22/1/08 at 10:46 PM |

|

|

I don't disagree at all, sorry if my forst post came over as negative!

I think its a great idea and as you say, given an hour on the lathe i could knock up something comparable with some bushings in it that would be quite

nice (cylindrical grinder even better for doing the allen key!)

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

smudger748s

|

| posted on 22/1/08 at 10:58 PM |

|

|

no offence taken

|

|

|

TheGecko

|

| posted on 23/1/08 at 12:46 AM |

|

|

Here's some pics I found on the web quite a while ago showing a similar approach to the same problem.

Cheap bead roller 1

Cheap bead roller 2

Cheap bead roller 3

I must say I do like the use of the grinder backing wheels as dies in yours.

Dominic

|

|

|

smudger748s

|

| posted on 23/1/08 at 10:52 AM |

|

|

Hi Dominic looks ok i used the backing wheels because i had a couple laying about and they are hardened steel

also the allen key is hardened too.

if i had a lathe i'm sure a better more refined tool could be made quite cheaply i'm pretty sure somebody on this forum will use the idea

and come up with a decent example we could all have regards Paul

|

|

|

paulf

|

| posted on 23/1/08 at 03:38 PM |

|

|

I used my lathe to do the same thing , I put a bit of bar in the chuck and turned it to shape and then mounted a bit of tufnol in the toolpost with a

groove in it to form the adjustable die, it worked ok on the alloy tube I used .

Paul.

|

|

|

02GF74

|

| posted on 25/1/08 at 02:18 PM |

|

|

I was thinking of an even simpler (cruder) design that does not use rollers.

Think of a pair of tongs made from steel plate, 3-5 mm thick, one has the male part of the bead and other the female.

The tube is inserted and the top piece is hammered down, the tube rotated a bit hammered etc until the bead is formed all the way round.

spot the deliberate mistake  the male and female forms are the wrong way round ... but you get the idea. the male and female forms are the wrong way round ... but you get the idea.

[Edited on 25/1/08 by 02GF74]

Rescued attachment bead.jpg

|

|

|

blueshift

|

| posted on 25/1/08 at 06:52 PM |

|

|

Hammery thing looks pretty simple.

there was one on the site a while back, someone welded some bits onto mole grip jaws, similar idea to the hammer thing but grip, release, turn,

repeat.

|

|

|

procomp

|

| posted on 29/1/08 at 09:36 AM |

|

|

Hi a good site with all sorts of info regarding bead rollers and tube/pipe benders is PRO-TOOLS An

American company but have dealt with them many times and offer a good reliable service.

Cheers Matt

|

|

|