John Bonnett

|

| posted on 19/10/22 at 06:39 PM |

|

|

Beaded or non beaded radiator hose joiners?

I just wondered what your opinions are? I don't have access to a machine to bead tube and although one can buy lengths of aluminium tube with

beaded ends they are not necessarily the right length for the application. My worry is that if the tube isn't beaded the hose could come off when

under pressure.

I have seen a Mole grip modified to press an indentation into a tube and here's the question. Would one indentation or the opposite really an

upwards indentation be sufficient to retain the hose? I would have thought it would.

Opinions please.

|

|

|

|

|

Slater

|

| posted on 19/10/22 at 06:48 PM |

|

|

I modified some mole grips with ball bearing on one jaw and a nut on other jaw, then clamped it around the circumference quite a few times to make a

bead, seemed to work OK and my hoses have not popped off in 15,000 miles.

Had to squeeze very hard and the ali pipes are quite thin wall though, actually started life as an original external bag type hoover extension

section. very Locost indeed.

Why do they call Port Harcourt "The Garden City"?...... Becauase they can't spell Stramash.

|

|

|

big_wasa

|

| posted on 19/10/22 at 06:55 PM |

|

|

With the skills you have you can cobble one together in no time.

[Edited on 19/10/22 by big_wasa]

|

|

|

Sanzomat

|

| posted on 19/10/22 at 07:38 PM |

|

|

The builder of my Locost drilled a couple of holes in the ali tube and put pop rivets through. It does give a small impediment to flow through the

joiner but does also create a bump on the outside that seems to be doing the job of preventing the hoses slipping off. Not sure if this is a good idea

or not but it seems to be working.

|

|

|

Mike Wood

|

| posted on 19/10/22 at 08:52 PM |

|

|

John

Might be worth contacting Think Automotive to see if they can make up a beaded tube to the correct length for you: https://www.thinkauto.com/

Have you checked out the Aeroflow tools in 3/8”, 1/2” and 5/16” sizes for approx £30: https://www.b-gdirect.com/hose-and-fitting-tools (or the Earls

version, but not sure on price: https://www.earls.co.uk/earls/accessories/tools/beadingtools.html ) as this seems more affordable than the lovely

looking wheeled beading machines such as: https://www.thinkauto.com/cgi-bin/sh000001.pl?WD=beading%20tool&PN=Pipe%2DBeading%2DTool%2Ehtml#aPBT1 or

https://www.motamec.com/motamec-water-hose-tube-pipe-bumping-beading-tool-for-16mm-and-larger-hoses-bead.html or

https://www.serckmotorsport.co.uk/product/aeroflow-af98-2017-pipe-beading-tool-large-bore/ or

https://www.t7design.co.uk/t7design-aluminium-tube-swaging-beading-beader-tool-bb9-0e7-e29.html Or one used by aircraft mechanics:

https://www.lasaero.com/products/article/Z02SN9NKL

Bet you could make a suitable tool!

Cheers

Mike

[Edited on 19/10/22 by Mike Wood]

[Edited on 19/10/22 by Mike Wood]

[Edited on 19/10/22 by Mike Wood]

[Edited on 19/10/22 by Mike Wood]

[Edited on 19/10/22 by Mike Wood]

[Edited on 19/10/22 by Mike Wood]

[Edited on 19/10/22 by Mike Wood]

[Edited on 19/10/22 by Mike Wood]

|

|

|

ianhurley20

|

| posted on 19/10/22 at 09:13 PM |

|

|

Hi John - I modified a pair of pipe grips (pliers) with an exhaust clamp and a creative bit of weld. It worked perfectly yo make a bead in radiator

tube, don't have aphoto at the moment but if you find the idea interesting I'll take one and post it. I am soon to use it again with my

latest car project using MX5 Mk 2 1.6 engine and Henry vacumn tubes for the pipe work

|

|

|

Schrodinger

|

| posted on 20/10/22 at 07:06 AM |

|

|

I was lucky enough to be given a beading tool similar to the one Big Wasa illustrated, however I have passed it on to another member on here.

They may see this and offer it on.

Keith

Aviemore

|

|

|

BenB

|

| posted on 20/10/22 at 07:07 AM |

|

|

I would be tempted to get some thin Ali bar, make a Hoop and then braze it in place using one of those Ali "welding" kits. Or just jb weld.

Nice fillet on the tube end side, less on the inner aspect (to create a more abrupt transition to further reduce slippage risk).

|

|

|

JimSpencer

|

| posted on 20/10/22 at 07:24 AM |

|

|

Hi

Oyster pliers are what's normally used (BES flog them I think..) they insert a dimple into the ally, and you just continue round the tube and

get the bead you need.

HTH

|

|

|

40inches

|

| posted on 20/10/22 at 08:39 AM |

|

|

quote:

Originally posted by JimSpencer

Hi

Oyster pliers are what's normally used (BES flog them I think..) they insert a dimple into the ally, and you just continue round the tube and

get the bead you need.

HTH

This is what I used, a bit fiddly but I have beaded dozens of tubes 8mm to 38mm.

https://www.bes.co.uk/standard-pliers-for-oyster-fitting-ibp-conex-16909/

|

|

|

Theshed

|

| posted on 20/10/22 at 09:24 AM |

|

|

Could you not run a cold tig bead around each end?

|

|

|

John Bonnett

|

| posted on 20/10/22 at 09:35 AM |

|

|

Some great ideas you've put forward and I'm very grateful to you all for taking the time to reply. I have a feeling that just one bump would

be sufficient to stop the pipe from blowing off because it wouldn't be able to slip past the clip.

|

|

|

indykid

|

| posted on 20/10/22 at 09:52 AM |

|

|

As The Shed said, as a man with a TIG welder, three short stitches around the pipe will do an ample job

|

|

|

big_wasa

|

| posted on 20/10/22 at 10:50 AM |

|

|

quote:

Originally posted by Schrodinger

I was lucky enough to be given a beading tool similar to the one Big Wasa illustrated, however I have passed it on to another member on here.

They may see this and offer it on.

That was the v1 I cobbled together.

|

|

|

big_wasa

|

| posted on 20/10/22 at 11:02 AM |

|

|

Pete Clayton was also looking to use it if either of them show up.

|

|

|

SJ

|

| posted on 20/10/22 at 11:08 AM |

|

|

quote:

Originally posted by John Bonnett

Some great ideas you've put forward and I'm very grateful to you all for taking the time to reply. I have a feeling that just one bump would

be sufficient to stop the pipe from blowing off because it wouldn't be able to slip past the clip.

I didn't bead mine and have had absolutely no issues with hoses coming off. As long as the pipe and hose are properly matched for size, and

assmbled dry there's no need to bead them.

|

|

|

padrc66

|

| posted on 20/10/22 at 12:54 PM |

|

|

as mentioned above, i made my own joiners from 32mm aluminium aerial mast from B&Q with a couple of pop rivets in each end - no problems in 3

years.

|

|

|

coyoteboy

|

| posted on 20/10/22 at 02:27 PM |

|

|

All too complex - get something conical and hard and smack it down onto it, flaring the ends little. Does the same job.

|

|

|

number-1

|

| posted on 20/10/22 at 05:06 PM |

|

|

I used hairspray on non welded/ beaded tube when working on the single seater Roadrunner racing SR1. Coat the outside of the ali tube with hairspray

and attach the silicone pipe, clamp it down and let it dry for a few mins

|

|

|

rdodger

|

| posted on 20/10/22 at 06:33 PM |

|

|

Hi John

I have a couple of these http://www.earls.co.uk/earls100/earls_shop/index.php?main_page=index&cPath=277_17_157

What size pipe are you using? I have one for 1" 1/4 32mm tube and one for 5/8" 15mm tube

You are welcome to borrow them .

|

|

|

John Bonnett

|

| posted on 20/10/22 at 07:20 PM |

|

|

quote:

Originally posted by rdodger

Hi John

I have a couple of these http://www.earls.co.uk/earls100/earls_shop/index.php?main_page=index&cPath=277_17_157

What size pipe are you using? I have one for 1" 1/4 32mm tube and one for 5/8" 15mm tube

You are welcome to borrow them .

Thanks Roger, PM sent.

|

|

|

bccox18

|

| posted on 21/10/22 at 09:54 AM |

|

|

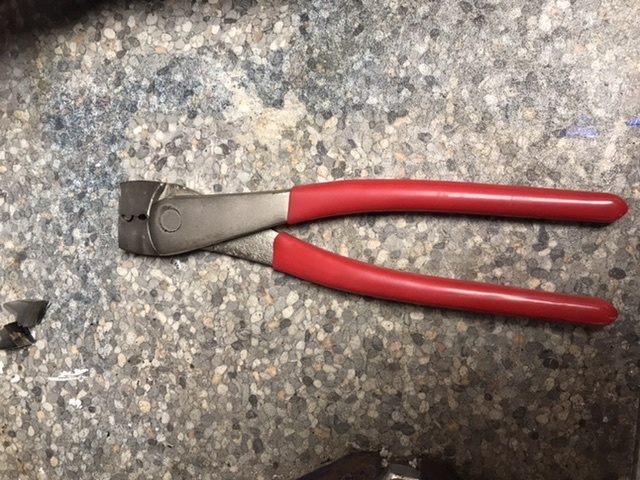

For putting a bead on my coolant pipes, I ended up buying a pair of these Dennett crimping pliers…

Pliers

Description

Cutting the tip of them off…

Description

And after a bit of filing to smooth the edges off on the crimp surfaces it gave a decent bead for not a lot of outlay.

Description

Thanks

Bob

[Edited on 21/10/22 by bccox18]

|

|

|