Irony

|

| posted on 13/1/11 at 01:00 PM |

|

|

Viento V8 Engine In!!

Happy New Guys! Hope you all had a good time!

I slotted my Rover V8 into the Viento last weekend and I must say it went it easy as wink! I cut lifting chains exactly to the Range Rover Spec and

the engine lifted perfectly horizontally with the Gearbox attached. I then found that a horizontal engine just doesn't seem to work. I

lengthened the rear chains and the engine went it a doddle. (anyone doing this should U2U for engine chain lengths).

I have a few questions for you fellow V8 Viento owners.

I know that generally the further back the better and at least on Viento owner (GeoffW) has got his engine right back but I cannot see how I can get

mine anywhere near as far back. How Critical is engine placement and how did you guys measure it so it was 100% in the middle, straight?

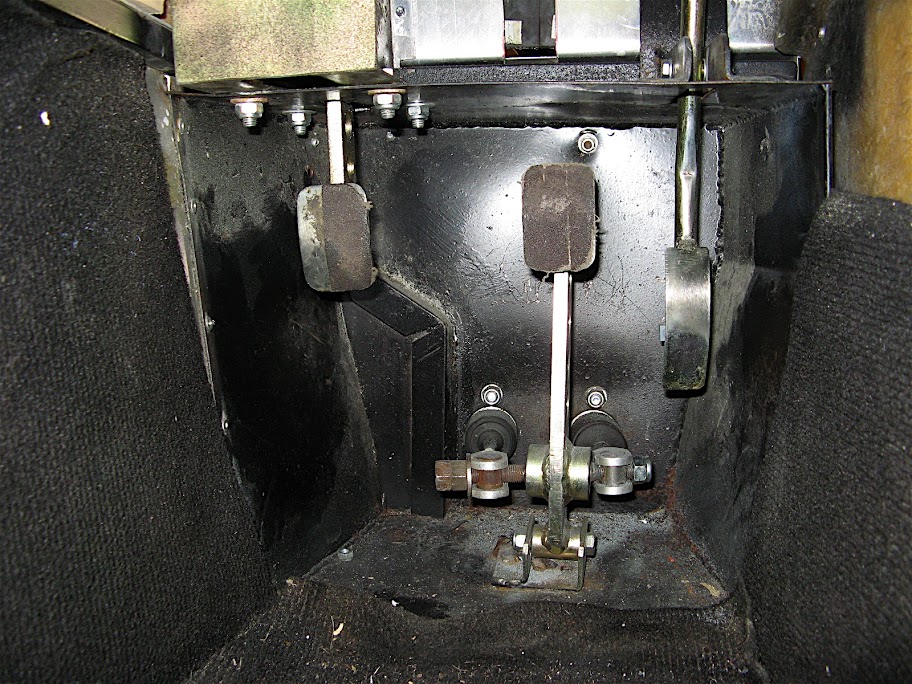

The furthest I could get the engine back was in the attached image. I can't sit any further back to to clashing with the clutch cylinder and my

gearbox mount rubbers clash in the tunnel.

The output shaft on the LT77 is quite close to the downright tunnel supports as well. Any further back and I be worried.

I have proper engine mounting rubbers but I have yet to drill the mounting holes for them. Any comments would be eagerly read!

Description

Description

Description

Description

Description

|

|

|

|

|

jossey

|

| posted on 13/1/11 at 01:32 PM |

|

|

well done mate. looks good.

dave.

Thanks

David Johnson

Building my tiger avon slowly but surely.

|

|

|

IanBrace

|

| posted on 13/1/11 at 02:31 PM |

|

|

Nice one Kevin, did you buy a crane or borrow another? Mine is creeping slightly but not enough to stop us using it to get the mini engine out..

www.aerialphotography.org.uk

|

|

|

Irony

|

| posted on 13/1/11 at 02:36 PM |

|

|

I got a Machine mart gift voucher and I thought I might as well get one. I think it has been worth it to be honest as will use it lots get the car on

and off the trestles etc. It went in easier than I thought.

|

|

|

scudderfish

|

| posted on 13/1/11 at 03:04 PM |

|

|

So when do we see the start up vid?

|

|

|

Irony

|

| posted on 13/1/11 at 03:10 PM |

|

|

quote:

Originally posted by scudderfish

So when do we see the start up vid?

After I have bought and built the cooling system, ignition system and hired a torque wrench to do the front pulley up. Couple of days perhaps!

|

|

|

franky

|

| posted on 13/1/11 at 04:34 PM |

|

|

I'll lend you a torque wrench if you need one.

|

|

|

IanBrace

|

| posted on 13/1/11 at 07:05 PM |

|

|

3 or 4 torque wrenches here too mate... from very low torque ones to a BIG one!

www.aerialphotography.org.uk

|

|

|

Paul (Notts)

|

| posted on 13/1/11 at 07:50 PM |

|

|

Looks good...

cant tell from photos if you have, but I placed wooden blocks under the engine mounts to represent the thickness of the engine mout rubbers. Wiill

have a look how far mine is back tonight..

you have to make sure the gear stick is in a good position and will hot hit the dash when in gear.

did you have to cut the plate for the rear of the gear box. I had to remove an inch or so to get the back of the gear box in.

Paul

fittingthe gear remote whit the box in is a nightmare if the side pannels are on but possible.

|

|

|

mgmiller

|

| posted on 13/1/11 at 10:03 PM |

|

|

Having worked on a Viento with a V8 I have to agree with ^^^^^^^^^^^

The gearbox remote take up a lot of room in the tunnel and you want to get the gearlever far enough back not to hit the dash.

|

|

|

eddie99

|

| posted on 13/1/11 at 10:04 PM |

|

|

Looking good, keep us updated

http://www.elitemotorsporteng.co.uk/

Twitter: @Elitemotoreng

Facebook: http://www.facebook.com/pages/Elite-Motorsport-Engineering/153409081394323

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

Irony

|

| posted on 14/1/11 at 08:40 AM |

|

|

But I don't see how it can go further back. The output shaft on the gearbox is getting close to the chassis down sections and the gap between

the down sections is 100mm and the radius of the shaft is 99mmish.

Then there's the clutch master cylinder. The bell housing is close to that as well. The only was I can think is to have a remote clutch fluid

resevoir, resivoir, resevor, tank. Is this possible?

I just looks as if its just not designed to go further back.

|

|

|

scudderfish

|

| posted on 14/1/11 at 10:31 AM |

|

|

My Fury has a floor mounted brake pedal, and top hanging clutch and accelerator in order to make room for it all. It's a very tight footwell,

and the passenger has even less room.

Here's an old picture of my pedals (I've fixed the brake pedal since) If you look at where the outer pedals are in relation to the brake

cylinders, you'll get an idea of the squeeze. Having said that, it works well.

Regards,

Dave

[Edited on 14/1/11 by scudderfish]

|

|

|

wilkingj

|

| posted on 14/1/11 at 07:30 PM |

|

|

I used a Land Rover Series 3 Clutch Master Cylinder as it has a smaller reservior. Cheap enough from paddockspares.com

That gives you a bit more room to shift the engine nack a few more milimetres.

The LT77 box is a very tight fit. I dont recall the propshaft flanges being within 2mm of the chassis uprights.

But it was a really close fit.

If its within 2mm, then any rocking of the engine could make it touch the chassis.

There are several pics in my Viento Build folder showing the gearbox fitting.

I think as mine is a little further back the flange is not so close to the tunnel uprights.

I had the cut away some of the rear mounting support to get the gearbox that far back. There is a picture from below showing that as well. Picture is

from beneath the car.

Have a look at my build pics, it shows where the lever comes out, and that was one of the factors I used in its final position.

There is a very little room to manouver in the tunnel.

Also dont fit the side panels (permanantly) until you have the gearbox in. Dont forget to make access holes for the filler / level plug, and the

speedo cable. You cant get a spanner in there with the sides on.

1. The point of a journey is not to arrive.

2. Never take life seriously. Nobody gets out alive anyway.

Best Regards

Geoff

http://www.v8viento.co.uk

|

|

|

Paul (Notts)

|

| posted on 15/1/11 at 12:09 PM |

|

|

The back of my engine is 4inches from the rear chassis rail in the engine bay...Yours looks the same so it should be fine. Will get in the garage

tonight and have a look at the location of my ouput flange in the tunnel.

Its important at this stage to get everything right as moving it again is difficult.

try fitting the remote and gearstick (temp) and see how it looks.

Paul

|

|

|

Paul (Notts)

|

| posted on 15/1/11 at 12:10 PM |

|

|

One up and running you will need to make some simple engine stays to reduce the movement of the engine. This stops the gearbox from moving more that a

couple of mm

Paul

|

|

|

Irony

|

| posted on 16/1/11 at 12:07 PM |

|

|

Thanks for all the replies. I think I have sorted the problem now. The problem was the mounts I bought from Luego. The main engine mounts were

wrong as the holes for the engine mounts were 10mm out and I had to get them remade. I also sourced from them the gearbox mount as well. When the

mount and rubbers were bolted onto the gearbox the rubbers fouled the chassis and would not allow the engine any further back. I spent yesterday

experimenting with new gearbox mounts and came up with a design that allows the engine further back.

However the Girling clutch master cylinder still fouls the bell housing. The tank does however unscrew but I will need to get some sort of cable to

make a exturnal link to the tank.

Thanks for all the replies guys.

|

|

|

rusty nuts

|

| posted on 16/1/11 at 12:15 PM |

|

|

Sounds like a remote reservoir master cylinder is what you need, not the integral type?

|

|

|

Irony

|

| posted on 17/1/11 at 09:54 AM |

|

|

Drilled the holes for the mounts and then realised they were wrong! Thew a tantrum a little bit and turned the garage lights and when inside and

drank beer. I have got the engine back as far as it will go. So far back in fact the engine lifting eye on the nearside fouls the chassis.

It'll have to come off eventually. The transmission tunnel just seems about 10mm to narrow to me. I put on the remote gear lever thingy and the

reverse switch fouls and chassis but I think I can solve that by lowering the gearbox mount with some fettling.

Another problem I have now come across is that on the remote gear lever housing there is the mechanism that makes it more difficult to go into

reverse. It's like to sprung setscrews and a couple of plates. This mechanism sticks out beyond the chassis and will foul any panels I put of

the side of the transmission tunnel. The remote housing itself is only about 7mm narrower than the tunnel. Which leaves me a gap of about 3mm on

each side. Is this normal?

Could one of you guys stick a tape measure and measure the width of your transmission tunnel for me, including the size of the box section?

Cheers for your help yet again.

|

|

|

Paul (Notts)

|

| posted on 17/1/11 at 08:07 PM |

|

|

Removed the reverse switch as I did not bother with a reverse light ( DO YOU NEED ONE FOR IVA ? ) and the mechanism to stop you putting it into

reverse does not work very well so left that off mine as well.

Paul

|

|

|

simonk

|

| posted on 17/1/11 at 09:24 PM |

|

|

Hi Irony

Have a measure across the tunnel - is yours an early chassis ? received wisdom is that they were narrower.

My LT77 went in very snug but ok, with the reverse detent and the reverse light switch in place. However, I slimmed down the reverse detent adjuster

bolts as far as I dared and also slimmed down the remote case a little - slowly by hand - with a file.. The reverse detent just tucks behind the

upright tube in the tunnel.

The block / bellhousing joint is about 3 1/2 inches from the scuttle tube with the ally panel fitted. The lifting mount bosses on the heads are about

1/2 inch from the chassis diagonals on each side, and I had to chop about 1 1/2 inches out of the gearbox mounting plate. The small reservoir Girling

integrated clutch master cylinder sits about 3/4 inch from the bellhousing.

Personally I wouldn't run without the reverse detent. Without the detent it's easy to get reverse rather than first at a standstill, and a

full bore start backwards is quite character building I understand - esp. for the person behind ! Also easy to find reverse coming down from second,

which will get you a lot of noise and a box full of expensive teeth. Once you've shortened the lever a bit the gate's quite tight.

If you are anywhere near Beds, Cambs, Herts (or are happy to travel) you're very welcome to come have a look around it and see what I did.

Cheers

Simon

|

|

|

Irony

|

| posted on 18/1/11 at 11:27 AM |

|

|

I have a feeling that my chassis might be a little bit of a early one. I did buy it secondhand. I have done some measuring.

Width of the tunnel including chassis rails but no panels 135mm

Tunnel Chassis rails 18mm

Width of remote gearchange unit 90mm

135 - 18 - 18 = 99mm

So the gap between the chassis rails in the tunnel is 99mm and my remote gearchange is 90mm that leaves me with 4.5mm on each side of the remote

gearchange. Not much.

I have still got some fettling to do regarding the gearbox mount so I think I will have a go at trimming the remote gearchange down a bit and see what

I can do with the reverse indent.

Thanks for the offer to come and have a look at your car Simon, I might just take you up on that offer at some point.

|

|

|