David Jenkins

|

| posted on 14/9/07 at 02:55 PM |

|

|

Woe! woe! and thrice woe!

Took the toy car out to get some petrol. When I got home, the ticking that's been worrying me a bit over the last few months was noticeably

louder. Looked under the bonnet, tried to locate the noise - and found that my centre exhaust manifold had blown.

Nice to know it wasn't anything too bad, but I did some investigation to see why it had gone - the mounting faces on the manifold aren't

in line with each other, so the plate was tight on one side and slack on the other. Job no. 1 - make all the mounting faces level and in line with

each other.

While I was there, I pulled the whole exhaust system apart. Job no. 2 - repaint all of the exhaust with VHT paint when I've finished.

Again, while I was there, I opened up the silencer to see why it's been getting noisier. Job no. 3 - repack the silencer (or about a quarter

of it, anyway).

Job no. 4 - order new gaskets (done).

I might try the silencer baffle proposed in this thread, where there's a

baffle roughly 1/3 of the way down the tube. Easy enough for me to do at this time, for very little effort.

Still, if I wanted 100% reliability I should have built a Toyota!

|

|

|

|

|

Confused but excited.

|

| posted on 14/9/07 at 03:16 PM |

|

|

It's not unreliable, it's got character. That's why we love them.

Tell them about the bent treacle edges!

|

|

|

bimbleuk

|

| posted on 14/9/07 at 05:04 PM |

|

|

Your not the only one. My nice shiny SS exhaust manifold is just the same. I've managed to seal it temporarily with high temp silicon RTV.

I'll take it off soon and get the face machined flat (I've tried using a file!).

As for the baffle I'll probably post a result tomorrow. The can on the Radical I help spanner now has one as its usually 107/8 db every time at

the scrutineers. W'e'll see if it makes any differnece.

|

|

|

rusty nuts

|

| posted on 14/9/07 at 05:46 PM |

|

|

Had a problem with my lolocost manifold not being flat , tried bolting up to a spare head with spacers on the outer ends with no luck . In the end I

took a hacksaw to it so that instead of one large (distorted ) plate it is now in three sections with the 2 center pipes together and the outers on

their own . Had no problems in the last two years .

|

|

|

907

|

| posted on 15/9/07 at 07:24 AM |

|

|

To cut or not to cut.

This thread has got me thinking.

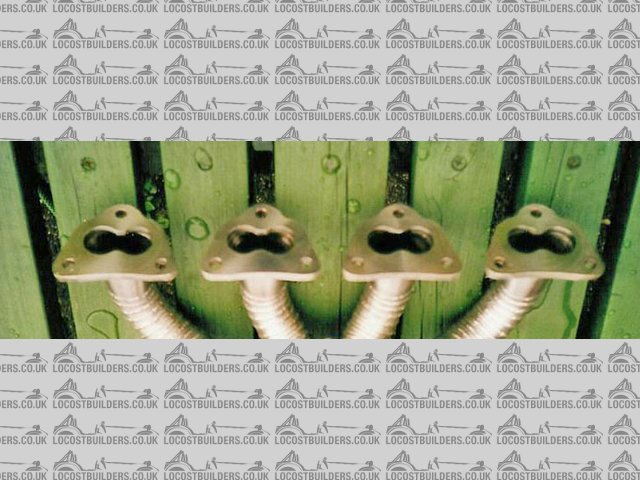

I'm making an exhaust manifold for a Zetec (Epona) at the moment and I'm now wondering if the different

expansion rates of a s/s flange and the Zetec cylinder head is an issue.

Would it be better to keep the flange in one piece, or cut into four pieces after welding the pipes in?

As you can see I have made a jig to hold it flat while it's being welded.

Your thoughts please.

Paul G

p.s. Sorry for the hijack.

Rescued attachment Zetec-flange-002-s.jpg

|

|

|

David Jenkins

|

| posted on 15/9/07 at 08:05 AM |

|

|

Mel - My manifold is in 3 parts, just like yours. My problem is that the middle flange is not quite parallel to the other 2, being tilted back a very

small amount. I've ground off a few humps and bumps that were not helping, and I think I've now got it sorted (fingers crossed). A fresh

set of gaskets should help too - the old ones had been on and off a few times.

Paul - Purely guessing, but it might be wise to weld it all up, then split the 4 pieces to allow of expansion as you suggest. An alternative would be

to allow for expansion by cutting slots between the flanges, but that's probably more trouble than it's worth. I'll leave it to

someone with practical experience to answer that one!

|

|

|

907

|

| posted on 15/9/07 at 09:04 AM |

|

|

The advantage of 4 pieces is that after welding the first stub on, it can be turned in the lathe to give a true face,

then put in a jig for the remaining welding.

I made my Lotus one this way but the bolt patten allowed this to be done. (see pic)

I like the idea of slots though.

Paul G

Rescued attachment lotus-pics-065-s.jpg

|

|

|

David Jenkins

|

| posted on 15/9/07 at 01:10 PM |

|

|

Well, I've put it all back together.

No more leaks

It's repainted

The silencer's repacked

I've added the baffle

I have a feeling that the baffle has had some effect, but I can't say with any certainty. The car seems significantly quieter, but I have just

replaced about one quarter of the packing that had disappeared over the last 8 or 9 months.

The only way to tell would be to do a proper noise test and compare the results to previous results, i.e. when I went for the SVA (about 101dBA) and

when tested at a track-day (about 100.5dBA). On both those occasions the silencer was either new or recently repacked.

Subjectively though, I think it is quieter.

|

|

|