chrsgrain

|

| posted on 6/11/09 at 12:24 PM |

|

|

OT stepper motor and controller help needed

Hi all,

This is very OT, but I don't know where to start with this, and I'm sure some of you guys will be able to help point me in the right

direction at least!

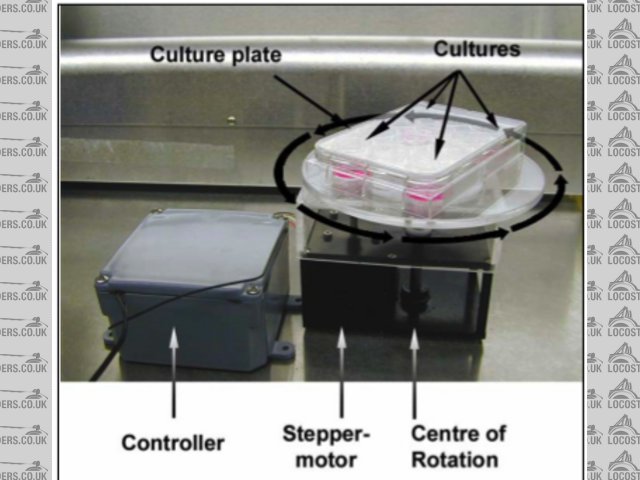

I need to make something like this;

Description

The idea of it is to generate shear stress in the pink dishes in the top plastic thing. In order to do this I need to be able to able to vary the

rate of acceleration of the stepper motor and to be able to make it start and stop at between 0.5 and 1Hz, this will give the pink dishes a linear

acceleration which will mimic the linear acceleration of air over the lining tissue of the lung - and let me look at whether that movement affects

people with asthma differently to people without asthma.....

Any ideas?? I can't ask the person who made it, as there is competition even between scientists!

Ta

Chris

Spoing! - the sound of an irony meter breaking...

|

|

|

|

|

Bluemoon

|

| posted on 6/11/09 at 12:29 PM |

|

|

Been looking at something similar for a student MPhys project. I intend to use an Arduio microcontroller and stepper motor driver.

Take a look at:

http://www.arduino.cc/

and for the stepper motor driver:

http://www.oomlout.co.uk/motor-shield-for-ardui

no-kit-p-207.html?zenid=hjjbg8pmk98u3je5ta5df27527

Cheers

Dan

[Edited on 6/11/09 by Bluemoon]

|

|

|

ceebmoj

|

| posted on 6/11/09 at 12:50 PM |

|

|

just a quick thought but at its all rotating on top of the plate unless your samples are all are at fixed radius your results may not be particuly

repeatable

|

|

|

chrsgrain

|

| posted on 6/11/09 at 12:57 PM |

|

|

They will all be at a fixed radius, so that's not a problem. What is a problem is controlling the motor to change acceleration, slew speed and

braking rate, and duration of each movement. All the things I'm reading I don't even understand the language!!

Chris

Spoing! - the sound of an irony meter breaking...

|

|

|

Bluemoon

|

| posted on 6/11/09 at 01:54 PM |

|

|

Hi Chris,

The Micro-controller let's you do all that, the Ardunio is designed for Humanity types, you should be able to pick it up very quickly. There is

an Ardunio book as well.

All I would do is design a program that made the motor step at the correct rates.

The Arunio boards are cheap, buy one and get playing (won't cost much more than 50-100 quid at most)..

Other options are to by a commercial stepper motor control (that's not cheap).

U2U me if you want any more info. I am in the process of buying the boards myself, as I need to get it working for the new year when the project

starts.

Dan

|

|

|

MikeRJ

|

| posted on 6/11/09 at 05:02 PM |

|

|

Whilst it doesn't do exactly what you want (I think!) this

device has pretty much all the electronics you need to implement your solution at a great price (don't know what p&p is though).

It uses the Microchip C754 microcontroller, which is cheap version of the PIC16C54 intended for the Chinese market only. The great thing about

Microchips PIC controllers is that they are very good at maintaining backward pin compatibility. You could fit a 16F627A, 628A or 648A depending on

memory requirements and which is a nice little flash based micro. These can be programmed by numerous different cheap commercial or homebuilt

programmers, and there are probably more tutorials and code examples for the PIC on the web than any other micro.

|

|

|

NS Dev

|

| posted on 6/11/09 at 05:06 PM |

|

|

do you have any PLC's already laying around from other rigs?

If so, quite a few have add-on stepper motor control cards available, though not for as little as £100!

If memory serves me right, we were using an omron plc with stepper control on a recent machine, though memory might not serve me right!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

rf900rush

|

| posted on 6/11/09 at 05:09 PM |

|

|

Are you aware that simple stepper drivers do not have smooth motion at slow speeds.

A microstep driver may be better.

Will jerky motion be a problem?

|

|

|

chrsgrain

|

| posted on 6/11/09 at 05:11 PM |

|

|

Thanks Mike, Thanks Nat,

Problem is, I understood only about a third of each of your posts! This really is not my area of expertise, never done any electronic stuff at all...

I may have found something that will do the job, but I'm not sure...

Stepper motor thingy

What do you think? Can get it for £165, which looks almost too good to be true, the motor might not be up to much, and I can't find any more

about it than what is on that page...

CHris

ETS - yes jerky movement will be a problem, I need smooth acceleration and deceleration to give a shear stress

[Edited on 6/11/09 by chrsgrain]

Spoing! - the sound of an irony meter breaking...

|

|

|

NS Dev

|

| posted on 6/11/09 at 05:21 PM |

|

|

I am pretty vague on all this stuff as I used to do the mechanical bits and a colleague the electronics, though I did have a basic

understanding........

We certainly never used any cheap servo controllers, but then we were building production machines, so different ballgame

The later PLC's we were using were Omron Sysmac CJ1 units, and a trawl on their website yields this:

omron axis controller

we would use one of those modules attached to a sysmac CJ1 PLC unit and power supply, and which would then allow programming of accelerations,

decelerations etc etc to whatever you required using omron PLC ladder logic programming, which is pretty easy to do if you have some programming

experience.

A fairly cheap servo motor would then be able to drive your arrangement.

PS you're looking at a lot of money for these bits new, but a trawl on ebay throws up a used sysmac or two!

[Edited on 6/11/09 by NS Dev]

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

MikeRJ

|

| posted on 6/11/09 at 11:38 PM |

|

|

quote:

Originally posted by chrsgrain

Stepper motor thingy

What do you think? Can get it for £165, which looks almost too good to be true, the motor might not be up to much, and I can't find any more

about it than what is on that page...

CHris

ETS - yes jerky movement will be a problem, I need smooth acceleration and deceleration to give a shear stress

One thing I don't think you've mentioned is whether this needs to be a standalone device (i.e. you switch it on and it runs through a

pre-determined cycle of acceleration and braking), or whether you are intending to control it from something else (e.g. PC)?

The Luminary Micro kit looks like a nice system, but seems to be very limited as a standalone solution out of the box; you can switch it into position

mode and control the position of the stepper from a pot, or control the speed and direction of the stepper in a different mode. Most of the features

require you to connect the board to a PC running the supplied GUI software.

However, if you do need a standalone solution then since all the source code is supplied and has been designed to be integrated into other

applications, it wouldn't be a big job to customise the firmware (with some software experience...).

Stepper motors by their very nature turn in discrete steps which can cause vibration, but this can be managed in most cases.

If you gear down the stepper, provide a resilient drive system (e.g. toothed rubber belt), and ensure the output is loaded by some mass then vibration

will be minimised. In addition, you can use "microstepping" (supported by the Luminary kit) which divides step into multiple smaller

steps by modulating the drive waveforms, this also gives smoother torque at lower speeds where vibration is more likely to cause problems.

|

|

|

chrsgrain

|

| posted on 7/11/09 at 06:30 PM |

|

|

Hi Mike,

Thanks for that - it can be either stand alone, or we have a PC close to the incubator the whole thing needs to be in. You sound like you know what

you're doing with this lot!

Chris

Spoing! - the sound of an irony meter breaking...

|

|

|

02GF74

|

| posted on 7/11/09 at 06:45 PM |

|

|

this can be done using stepper motor whose movement can be controlled quite accurately.

if you are less stringent on your requirements, how about a car wiper motor? may need some electronics to accelerate/decellerate smootly.

... but that may be achievre by mechanical means,

[Edited on 7/11/09 by 02GF74]

|

|

|