Mr Whippy

|

| posted on 13/9/23 at 06:42 AM |

|

|

Expanding foam that doesn't expand too much

Hi,

I have a large 3D printed part that is twin walled and to add stiffness was wanting to inject expanding foam into the gap (20mm) but obviously

don't want it to balloon the part but just fill it. I have put holes to allow excess foam to escape. Anyone actually used a product they'd

recommend?

Thanks.

|

|

|

|

|

russbost

|

| posted on 13/9/23 at 08:51 AM |

|

|

I think pretty much all expanding foam on the market is the builders type product, which, so far as I'm aware is also basically the same stuff as

used in fibreglass structures etc. by mixing 2 separate parts that then expand. as long as you've allowed small holes for excess to escape

I'd have thought you'd be fine with an ordinary can from any DIY shop/builder's merchant.

If you're really concerned about ballooning you could use something that's solid. but doesn't expand like silicone sealant or Siroflex

etc.

I no longer run Furore Products or Furore Cars Ltd, but would still highly recommend them for Acewell dashes, projector headlights, dominator

headlights, indicators, mirrors etc, best prices in the UK! Take a look at http://www.furoreproducts.co.uk/ or find more parts on Ebay, user names

furoreltd & furoreproducts, discounts available for LCB users.

Don't forget Stainless Steel Braided brake hoses, made to your exact requirements in any of around 16 colours.

http://shop.ebay.co.uk/furoreproducts/m.html?_dmd=1&_ipg=50&_sop=12&_rdc=1

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

SteveWalker

|

| posted on 13/9/23 at 11:35 AM |

|

|

There are definitely two types - one for filling large voids, that expands a lot and the other for sticking plasterboard too walls and filling cracks.

The latter is probably what you want and usually refers to "low expansion" on the can.

|

|

|

nick205

|

| posted on 13/9/23 at 01:21 PM |

|

|

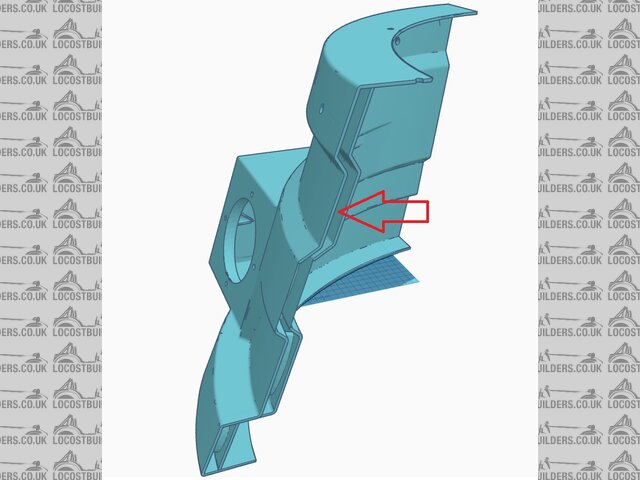

Is this a Dalek part?

|

|

|

JoelP

|

| posted on 13/9/23 at 03:06 PM |

|

|

Soudal plasterboard adhesive foam is what I use. Available at screwfix. It doesn't expand much at all. Window fitters use it to draftproof small

gaps.

Beware! Bourettes is binfectious.

|

|

|

MikeR

|

| posted on 13/9/23 at 03:15 PM |

|

|

What about the stuff you buy in separate cans and mix yourself. (Supplied usually from boat builders) You know the expansion ratio so only mix the

right amount?

|

|

|

craig1410

|

| posted on 13/9/23 at 10:47 PM |

|

|

Just get Screwfix No Nonsense expanding foam and then trim off any excess once cured. It's really easy to cut afterwards and the foam itself is

really quite robust in terms of structure and will add real stiffness to your project. I would also recommend the foam which works via a dispenser

"gun" rather than the stuff that has its own nozzle but you do carry the extra cost of the gun and maybe some gun cleaner. But it is MUCH

more controllable than the self dispensing cans.

|

|

|

Mr Whippy

|

| posted on 14/9/23 at 06:13 AM |

|

|

quote:

Originally posted by nick205

Is this a Dalek part?

Yes that right, it's the shoulders. I've added a double skin to increase stiffness with a 20mm gap and connecting blocks between the two

walls which are 2mm thick. I'm running off a test slice just now which will be ready tomorrow to check for errors and that it actually prints

correctly before the 3 weeks to print all the shoulder sections. I like the sound of "Soudal plasterboard adhesive foam" might get some and

try it in a small cardboard box and see what it does. Fortunately my office window looks right on a Screwfix  super handy! super handy!

Description

|

|

|

coyoteboy

|

| posted on 14/9/23 at 11:43 AM |

|

|

quote:

Originally posted by MikeR

What about the stuff you buy in separate cans and mix yourself. (Supplied usually from boat builders) You know the expansion ratio so only mix the

right amount?

This was my thinking, a controlled mix of foaming agent and adhesive.

|

|

|

coyoteboy

|

| posted on 14/9/23 at 11:46 AM |

|

|

quote:

Originally posted by craig1410

Just get Screwfix No Nonsense expanding foam and then trim off any excess once cured. It's really easy to cut afterwards and the foam itself is

really quite robust in terms of structure and will add real stiffness to your project. I would also recommend the foam which works via a dispenser

"gun" rather than the stuff that has its own nozzle but you do carry the extra cost of the gun and maybe some gun cleaner. But it is MUCH

more controllable than the self dispensing cans.

I think their problem is that when expanding it can do some real expansion damage on thin walled things. I've even had it push up a thin wooden

window cill, so a wee 3D printed part will be warped to buggery if the external areas cure first and the expansion keeps going.

|

|

|

harmchar

|

| posted on 16/9/23 at 08:59 PM |

|

|

Is two part epoxy resin an option. Won’t expand same as foam, but might be too heavy for your purpose.

|

|

|

Mr Whippy

|

| posted on 17/9/23 at 01:17 PM |

|

|

quote:

Originally posted by harmchar

Is two part epoxy resin an option. Won’t expand same as foam, but might be too heavy for your purpose.

Thanks for the suggestion but yes filling the gap with epoxy would probably make the part very heavy, although bomb proof

|

|

|