Craigorypeck

|

| posted on 15/2/11 at 09:08 AM |

|

|

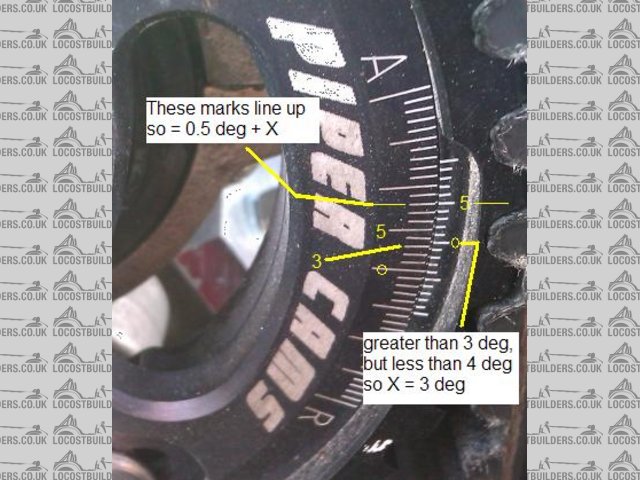

Reading a vernier pulley

Is this between 3 and 4 degrees advanced?? I just adjusted the cam to have max lift at 110 crank but not entirely sure what Ive ended up with...

confused my self yet again!

Not sure how to read a vernier.. from outside in or inside out..

|

|

|

|

|

Davey D

|

| posted on 15/2/11 at 09:19 AM |

|

|

If you go by the centre mark on each part of the pulley, then it looks to me like 4deg advance

|

|

|

MikeRJ

|

| posted on 15/2/11 at 09:24 AM |

|

|

About 4.5 degrees advanced. This should only be taken as a reference figure so you can set the same timing in the future however; it's not

likely to be particularly accurate (or rather the zero degree point is not likely to be very accurate).

|

|

|

mcerd1

|

| posted on 15/2/11 at 09:31 AM |

|

|

looks like 3.5 deg. in that pic to me - but its hard to tell exactly from a pic

basically you've got two back to back vernier scales (one for advance the other for retard) the split between them is at the mid point on each

scale (i.e. zero)

and here's how they work: http://en.wikipedia.org/wiki/Vernier_scale

once the cam is set to its recommended timming there is every chance that the pulley will not be at zero - this doesn't mater (I assume you used

a dial gauge or similar to set the timming? )

the position its in now is your new 'zero' point (although unfortunatly you can't zero the gauge) so if you want to adjust the

timming to look for more power (probably on a dyno) then your moving the timming relative to this point

[Edited on 15/2/2011 by mcerd1]

[Edited on 15/2/2011 by mcerd1]

-

|

|

|

Craigorypeck

|

| posted on 15/2/11 at 10:06 AM |

|

|

Thanks.. Was set with a dial gauge during the build.

So the middle of the outer set of lines is 0 and adjacent to that is the actual degrees and in my case approx 4 advanced? (my new 0)

Then the fine calculations are defined as in the wiki info...

[Edited on 15/2/11 by Craigorypeck]

|

|

|

mcerd1

|

| posted on 15/2/11 at 10:32 AM |

|

|

the inner scale is the fixed scale in degrees with its mid point also at zero

your outer scale is the sliding scale also with its mid point at zero (this scale is not in degrees but 0.9*degrees)

so use the mid point of the outer scale as the mark to read the inner scale with - get the number of degrees, but round it down to the nearest

whole degree

then find the mark on the outer scale that lines up with any of the ones on the inner scale (doesn't matter which one it lines up with, but it

should be amost perfectly lined up) - count along the outer scale from the mid point and thats in the 1/10th's of a degree to add to the whole

degrees

Vernier Scale

[Edited on 15/2/2011 by mcerd1]

-

|

|

|

MikeRJ

|

| posted on 15/2/11 at 10:33 AM |

|

|

quote:

Originally posted by mcerd1

looks like 3.5 deg. in that pic to me - but its hard to tell exactly from a pic

Yep, you are correct, I miscounted!

|

|

|

mcerd1

|

| posted on 15/2/11 at 10:34 AM |

|

|

quote:

Originally posted by MikeRJ

quote:

Originally posted by mcerd1

looks like 3.5 deg. in that pic to me - but its hard to tell exactly from a pic

Yep, you are correct, I miscounted!

so did I, hense the edit

hope the pic above makes it clearer....

[Edited on 15/2/2011 by mcerd1]

-

|

|

|

mcerd1

|

| posted on 15/2/11 at 10:43 AM |

|

|

btw - whats happened to the bolt on the end of your camshaft ?

-

|

|

|

Craigorypeck

|

| posted on 15/2/11 at 08:47 PM |

|

|

Thanks!!! That was a perfect explanation!! Many thanks for taking the time to make a wee diagram and all!

The cam bolt is back on now..

Cheers

|

|

|