907

|

| posted on 1/7/06 at 10:27 PM |

|

|

New Tig at last

After 8 days with no Internet  finally something to cheer me up. finally something to cheer me up.

My new Tig arrived.    (well second hand) (well second hand)

I've spent this week making up leads and a water cooler, locost style, and today was fire up time.

It's got more buttons than you can shake a stick at. It's got more buttons than you can shake a stick at.

I wonder what they do?

Paul G

aka Happy bunny

Rescued attachment Miller-200.jpg

|

|

|

|

|

NigeEss

|

| posted on 1/7/06 at 11:04 PM |

|

|

quote:

Originally posted by 907

It's got more buttons than you can shake a stick at. It's got more buttons than you can shake a stick at.

I wonder what they do?

Paul G

aka Happy bunny

Buttons, lots of 'em....just have to poke'em and see

|

|

|

Peteff

|

| posted on 1/7/06 at 11:19 PM |

|

|

Slope up, slope down.

Shut up, sit down  read the book. read the book.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

dl_peabody

|

| posted on 1/7/06 at 11:50 PM |

|

|

quote:

It's got more buttons than you can shake a stick at.

Surely one of those buttons must be the "toast" setting. Good for hotdogs, mashmellows and bread.

Actually I am quite envious WANT one so I can weld Aliminum.

[Edited on 1/7/06 by dl_peabody]

|

|

|

907

|

| posted on 2/7/06 at 07:54 AM |

|

|

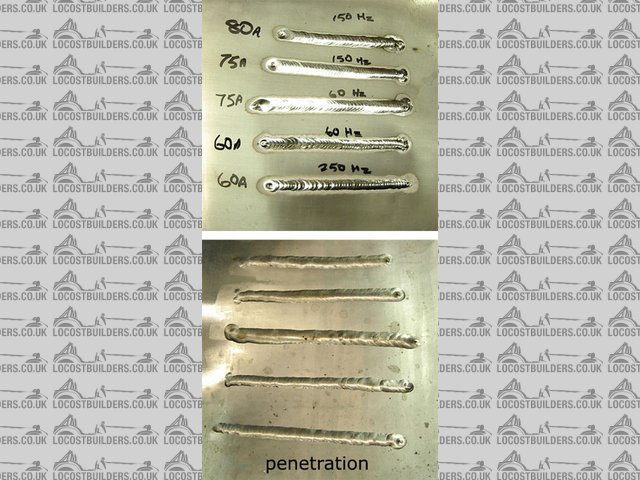

One of the buttons is for A/C frequency, 20 Hz to 250 Hz.

This is supposed to "focus" the arc, but apart from the change in the sound,

a sort of ZZZZZZ to a ZEEEEEEEE, I couldn't see much difference. See pic.

Still looking for the "make a cuppa" button.

Paul G

Rescued attachment Al-welds-m-s.jpg

|

|

|

John Bonnett

|

| posted on 2/7/06 at 08:36 AM |

|

|

I'm sure you are aware of the Miller website, http://www.millerwelds.com/education/tech_tips/TIG_tips/hints_tips.html which does contain a lot

of helpful information.

If you are new to TIG there are a couple of tips I can give you. One is to set the post gas to 5 seconds or even more. The other is to re-grind the

tungsten after you have a touch down. There are a number of TIG welders on this site who will be pleased I'm sure to advise you if you have any

problems. It really is very a very satisfying technique and once mastered you will not use MIG anymore. Well I haven't anyway.

John

|

|

|

Peteff

|

| posted on 2/7/06 at 09:12 AM |

|

|

Was it from America Paul and did you have to pay duties and vat on it ?

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

907

|

| posted on 2/7/06 at 10:13 AM |

|

|

quote:

Originally posted by Peteff

Was it from America Paul and did you have to pay duties and vat on it ?

It was "on loan" from Miller UK to Ipswich Tech.

They have now placed orders for several Syncrowaves.

A sprat to catch a mackerel.

Paul G

|

|

|

John Bonnett

|

| posted on 2/7/06 at 10:21 AM |

|

|

Hi again, If you did a welding course at Ipswich Tech. please forgive me for telling you things you already know.

One other thing I did not grasp from my college course was that standard oxy acetylene rods are no good for TIG welding mild steel. If you do use them

the welds bubble and will be full of porosity. The problem is the oxide coming from the rods. It is important to use triple deoxidised rods and then

there will be no problem.

Cheers

John

|

|

|

wilkingj

|

| posted on 2/7/06 at 11:38 AM |

|

|

John,

Paul (907) is an Expert Coded Welder.

He could teach the College instructors a thing or two.

He is also very modest

What with him and TrevD who makes Gas Welding ally look like childs play, there are some good welders on here.

They Both P**s me off.. they make it look so simple.

As for me?... When it comes to welding, I am like Noel Edmunds Mate... Mr BLOBBY

PS.. No offence to John B, who, I am sure is a competent welder too

1. The point of a journey is not to arrive.

2. Never take life seriously. Nobody gets out alive anyway.

Best Regards

Geoff

http://www.v8viento.co.uk

|

|

|

John Bonnett

|

| posted on 2/7/06 at 12:31 PM |

|

|

My apologies Paul

John

|

|

|

907

|

| posted on 2/7/06 at 02:09 PM |

|

|

quote:

Originally posted by John Bonnett

My apologies Paul

John

None necessary John

No one's an expert. We are all merely at various stages of leaning.

There are things on the Miller that I haven't used before.

I think it's a case of suck it and see.

ATB

Paul G

|

|

|