Miks15

|

| posted on 27/12/09 at 08:31 PM |

|

|

idiots guide to fiberglassing please

Im going to be widening my scuttle soon and would like an idiots guide on how to do it.

It needs to be widened about 200mm so the plan is to make a mould over the current scuttle, then cut he scuttle, fit the mould over the now seperated

scuttle at the desired width and clamp etc, the lay up the inside, then remove the mould, then fill and finish.

So im after an idiots guide of exactly ow to do it, what to use and everything so i get it right. Including what resins and waxes etc to use.

Sorry for being a pain, just want to get it right first time.

thanks

Mikkel

|

|

|

|

|

clairetoo

|

| posted on 27/12/09 at 08:34 PM |

|

|

A better plan would be to cut and widen the scuttle , fill it smooth , then take a mold off that and make a new scuttle .

Any joins will show in time

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

orton1966

|

| posted on 27/12/09 at 08:36 PM |

|

|

as per u2u

As per u2u, I'm in Nott's and work with the stuff all day. If you can pop over I can help with advice on what you need and how to use it!

|

|

|

scootz

|

| posted on 27/12/09 at 08:36 PM |

|

|

Often wondered about this sort of thing too... how do you go about making a mould?

It's Evolution Baby!

|

|

|

mr henderson

|

| posted on 27/12/09 at 08:41 PM |

|

|

quote:

Originally posted by scootz

Often wondered about this sort of thing too... how do you go about making a mould?

There's loads of stuff on you tube, some of it quite good, you may need to put 'mold' in the search box because most of it is

American, and they can't spell mould.

(and 'fiberglass' will probably get more results than fibreglass  ) )

|

|

|

scootz

|

| posted on 27/12/09 at 08:46 PM |

|

|

Cheers!

It's Evolution Baby!

|

|

|

clairetoo

|

| posted on 27/12/09 at 09:21 PM |

|

|

A few tips here

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

mark chandler

|

| posted on 27/12/09 at 09:45 PM |

|

|

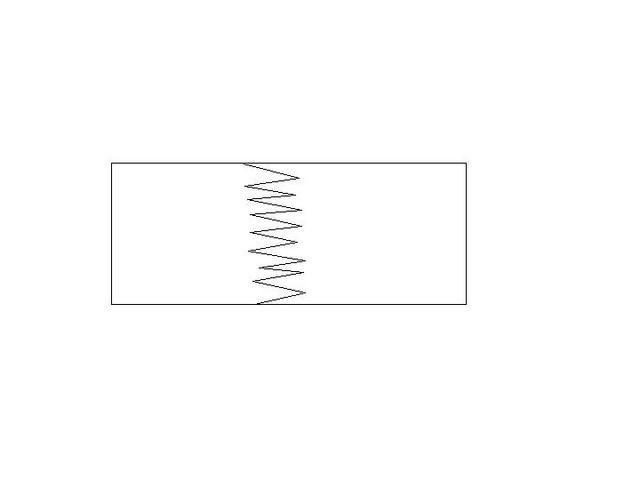

If you cut a straight line it will show, if you cut wide zig zags you greatly lengthen the bonded join so its stronger and no-longer have a single

failure point. It also lets you blend in.

I screwed my cut nose cone to some wood to hold it solidly, laid duck tape over the gel side and just layered fibreglass up on the inside edge.

Once cured removed duck tape, filled and sanded the top.

Cut like this VVVVVVV

[Edited on 27/12/09 by mark chandler]

Rescued attachment cut_like_this.JPG

|

|

|

Miks15

|

| posted on 27/12/09 at 09:56 PM |

|

|

i see what you mean mark, wouldnt it be better to have rounded edges on the cuts so theres no concentrated stress points?

But will defietly do this to make it stronger and look better

|

|

|

flibble

|

| posted on 27/12/09 at 10:06 PM |

|

|

Few more tips here, good place to buy it too.

|

|

|

mark chandler

|

| posted on 27/12/09 at 10:50 PM |

|

|

Rounded edges are good indeed, just lazy drawing, I used a jigsaw and wiggled my way along turning as tightly as possible.

If adding 2" make the spikes 2.5" long then you can cleanly bridge the gap, it helps maintain the smooth curve as well.

It's how the good hot rodders lower the rear roof, the lazy ones just cut straight and fill... It also means you will not see a straight crack

appearing as the scuttle flexes over time.

Regards Mark

|

|

|

Miks15

|

| posted on 27/12/09 at 11:13 PM |

|

|

well the problem is im actually adding about 9 inches, so will have to make the spikes quite long!

|

|

|

scootz

|

| posted on 28/12/09 at 09:27 AM |

|

|

9 inches isn't that big...

It's Evolution Baby!

|

|

|

RK

|

| posted on 28/12/09 at 02:15 PM |

|

|

How wide is your car?

For an easy way, that I have done successfully myself, if I may add, go to Kinetic Vehicles (Jack McCormack) and see how he does it. The key is to

hold the two sides in the exact position you are going to want, with the bits of wood. Then you fill it in and if you do a good job, won't have

to do a lot of bodywork.

Also search Mr. Whippy - widening cycle wings - thread on here.

[Edited on 28/12/09 by RK]

|

|

|

Miks15

|

| posted on 28/12/09 at 03:54 PM |

|

|

its not so much that the car is very wide, its more the shape i have made the chassis, normal bodywork wont fit properly, so the scuttle needs to be a

fair bit wider than normal

|

|

|