Poorscousertommy

|

| posted on 5/1/12 at 06:40 PM |

|

|

Wishbones and bushes

Hi all, just pressed in the bushes and crush tubes into first upper wishbone (front), and upon assembly crush tube was interference fit with bracket

(had to tap in with rubber mallet to get the bolts through).

Arm is quite stiff to move, and bushes rotate (should the bushes rotate in the wishbone, or the crush tube in the bush??)

Any ideas? Is this normal? If not, how do I get the bushes out or is it FUBARed??

Heeelp!

Off to paint my diff while you venerable lot fix my woes!!

|

|

|

|

|

TimC

|

| posted on 5/1/12 at 06:49 PM |

|

|

The crush tube should rotate in the bush which should be static in the housing.

|

|

|

phelpsa

|

| posted on 5/1/12 at 06:56 PM |

|

|

And they should rotate as freely as possibly ideally.

|

|

|

mark chandler

|

| posted on 5/1/12 at 07:40 PM |

|

|

Leave the bolts loose, only tighten once that car is fully loaded and on flat ground or you will destroy the bushes very quickly.

Regards Mark

|

|

|

phelpsa

|

| posted on 5/1/12 at 08:15 PM |

|

|

quote:

Originally posted by mark chandler

Leave the bolts loose, only tighten once that car is fully loaded and on flat ground or you will destroy the bushes very quickly.

Regards Mark

Only valid for bonded rubber bushes, not plastic ones with a free crush tube.

|

|

|

Poorscousertommy

|

| posted on 5/1/12 at 08:23 PM |

|

|

Thanks folks - great hints and tips.. So is there something I can do with the existing bushes? Now that theyre pressed, I'm buggered if I can

figure out how to get them out without damage.. Also, is there a common cause? Have I done something wrong? Should they be so tight in the bracket etc

etc?

I want to crack on with getting suspension assembled tomorrow, but don't want overly stiff, squeaky suspension!

Also, is there a knack to pressing? I am doing outer bush, then crush tube, then inner using a vice and going veeeery slowly!

Cheers

|

|

|

phelpsa

|

| posted on 5/1/12 at 08:27 PM |

|

|

quote:

Originally posted by Poorscousertommy

Thanks folks - great hints and tips.. So is there something I can do with the existing bushes? Now that theyre pressed, I'm buggered if I can

figure out how to get them out without damage.. Also, is there a common cause? Have I done something wrong? Should they be so tight in the bracket etc

etc?

I want to crack on with getting suspension assembled tomorrow, but don't want overly stiff, squeaky suspension!

Also, is there a knack to pressing? I am doing outer bush, then crush tube, then inner using a vice and going veeeery slowly!

Cheers

Unfortunately not an easy fix. Its that the bore on the housing is slightly too small causing the bush to be squeezed slightly. I overcame the issue

by removing the crush tubes and reaming the bore of the bushes (while in the wishbone) to 3/4". Others have overcome it by turning down the

crush tube slightly.

|

|

|

907

|

| posted on 5/1/12 at 08:33 PM |

|

|

As TimC & Phelpsa say, tight in the w/b but free to move on the crush tube.

My own crush tubes were a tight fit so after fitting them into the w/b tubes

I reamed out the i/d's

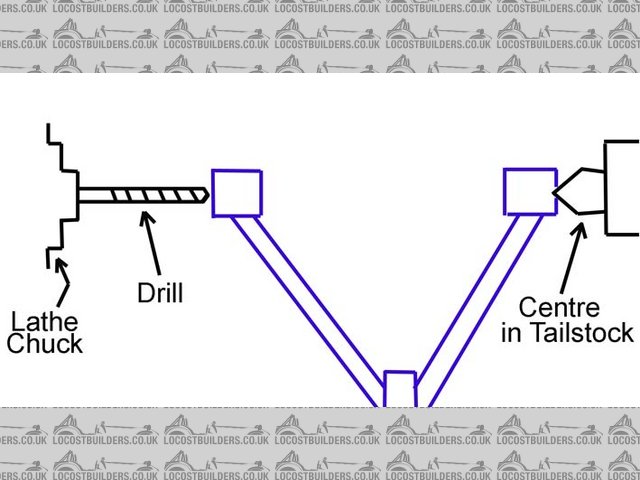

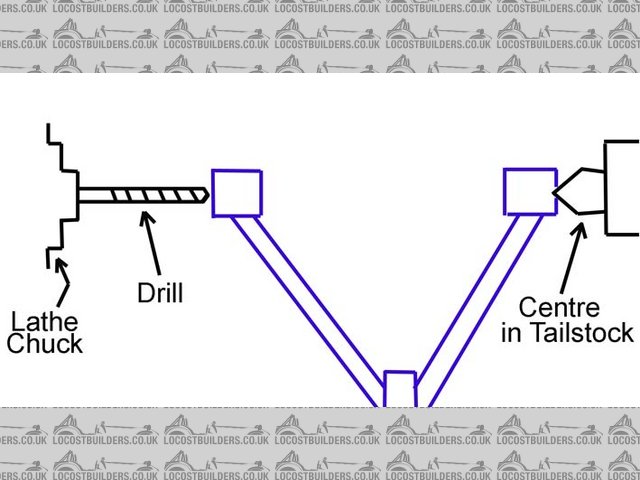

To ensure they were aligned I did this on my lathe, turning the chuck by hand

while winding the tail stock in. Turned the w/b around and did the other side.

The pic below shows the set up.

HTH

Paul G

Reaming poly bushes

|

|

|

Davegtst

|

| posted on 5/1/12 at 08:51 PM |

|

|

I put both bushes in before pushing in the crush tube. I then took it all back apart again as it was way too tight and would hardly move at all.

What I did was dremil out the powder coat inside the wishbone and clean up the crush tubes with sandpaper. After this it moves perfectly.

|

|

|

Mad Dave

|

| posted on 5/1/12 at 09:15 PM |

|

|

My crush tubes were a tight fit (persuaded with a mallet) and wishbones were stiff when I first fitted them. After 6 months on the road I took out

the wishbones to re-grease the bushes. I expected this to be a pain but the crush tubes just slid straight out (wear and distortion). I would only

ream the bushes if the were bronze and the crush tube was machined. Your crush tubes are made from stock 3/4 od seamless tube, it is not perfectly

circular. I'd leave it for now and crack on with the build

|

|

|

Bluemoon

|

| posted on 6/1/12 at 11:34 AM |

|

|

quote:

Originally posted by 907

As TimC & Phelpsa say, tight in the w/b but free to move on the crush tube.

My own crush tubes were a tight fit so after fitting them into the w/b tubes

I reamed out the i/d's

To ensure they were aligned I did this on my lathe, turning the chuck by hand

while winding the tail stock in. Turned the w/b around and did the other side.

The pic below shows the set up.

HTH

Paul G

Reaming poly bushes

Thanks 907, may try that approach, sure mine need looking at... I think you method is probably the best I have seen, making sure the bones only have

one axis of rotation..

|

|

|

procomp

|

| posted on 6/1/12 at 12:03 PM |

|

|

Hi

I wouldn't be to concerned with the inner crush / pivot tubes. If they are STD MK supply for the INDY R then you need to make new ones anyhow.

You'll find that the crush tube is 1/2" bore but with 12mm bolts and suspension mounting brackets on the chassis. That results in around 1

deg of camber change and a huge amount of toe change whilst driving down the road at the front end. But it's the same for all the bushes at the

rear also. !!!

Cheers Matt

|

|

|

Neville Jones

|

| posted on 6/1/12 at 12:22 PM |

|

|

Now now Matt, be nice.

Those who know what is what already know the Mk is not the most well thought out or executed car, but then again, hundreds of mugs who bought them

can't be wrong.  The MK looks great, just don't try and make sense of the (lack of) intelligent design thought (not) put into them. The MK looks great, just don't try and make sense of the (lack of) intelligent design thought (not) put into them.

Cheers,

Nev.

Where's that bloody flak jacket got to!

|

|

|

TimC

|

| posted on 6/1/12 at 02:31 PM |

|

|

In fairness, my Polyflex units still need fettling - very stiff.

|

|

|

bobinspain

|

| posted on 6/1/12 at 03:04 PM |

|

|

quote:

Originally posted by TimC

In fairness, my Polyflex units still need fettling - very stiff.

As Dick Emery would've said, "Oooo you are awful---!"

|

|

|