ftaffy

|

| posted on 1/10/12 at 11:39 PM |

|

|

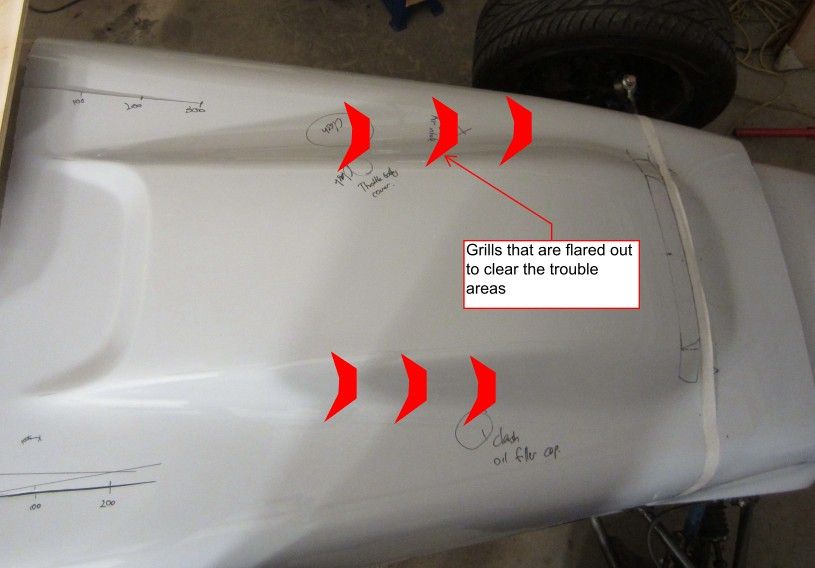

Bonnet Gills

Hey Guys,

I have seen some pictures on here before of bonnet gills being done, but for the life of me cant find them now. Can people please post photos of there

gills, small bumps etc on the bonnets so i can get some ideas of what to do here.

The issue i have is that my bonnet (with hump), will clash with my engine when sitting on the scuttle and nose cone.

The car is a locost, running M44 BMW engine that uses the BMW as a complete donour including uprights, etc.

Had to make custom rear uprights and a bolt on bearing carrier to suit the BMW press bearing.

cheers,

Taffy

|

|

|

|

|

blakep82

|

| posted on 1/10/12 at 11:57 PM |

|

|

how about 2 big aluminium (or fibreglass if you can?) air intake 'nostrils' either side of the main bulge in the middle?

would clear all the issues, and get some lovely cool air in too.

extend from the sides of the bulge, straight out, til the edge of the bonnet, and bend down so the end of the aluminium fits the meets the side of the

bonnet.

2 halfs of a subaru scoop might work?

can't really describe it any better than that, can't really draw it out either, but hopefully you get what i mean?

[Edited on 2/10/12 by blakep82]

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

ftaffy

|

| posted on 2/10/12 at 02:24 AM |

|

|

That does make sense.

I willl get some PVC pipe or maybe just cardboard and do a trial of how nostrils will work. If they look ok i can just glass them in so i have a

similar shape each side.

This is turning into one funky bonnet shape....

Cheers,

Taffy

|

|

|

designer

|

| posted on 2/10/12 at 07:21 AM |

|

|

Why not just take air out through the side panels? It's a lot less noticeable, and a lot less work.

|

|

|

craig1410

|

| posted on 2/10/12 at 08:43 AM |

|

|

I know clearance is your main issue not airflow but if you are cutting vents, design them to get hot air our rather than cold air in. The Locost gets

plenty of cold air in through the nosecone typically but has difficulty getting rid of the hot air once it has passed through the engine bay. Also,

try to angle the vents so that forward motion will not cause water (ie. rain) to be drawn in to the engine bay all over your electrics.

Getting good engine bay airflow can make a big difference to engine cooling.

|

|

|