Volvorsport

|

| posted on 5/9/14 at 06:54 AM |

|

|

lotus elite series 1

Just wondering if anybody has a link or photo or remembers! How the transition from front suspension subframe goes into the shell.

can't find any stripped engine bays on google

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

|

|

Sam_68

|

| posted on 5/9/14 at 01:29 PM |

|

|

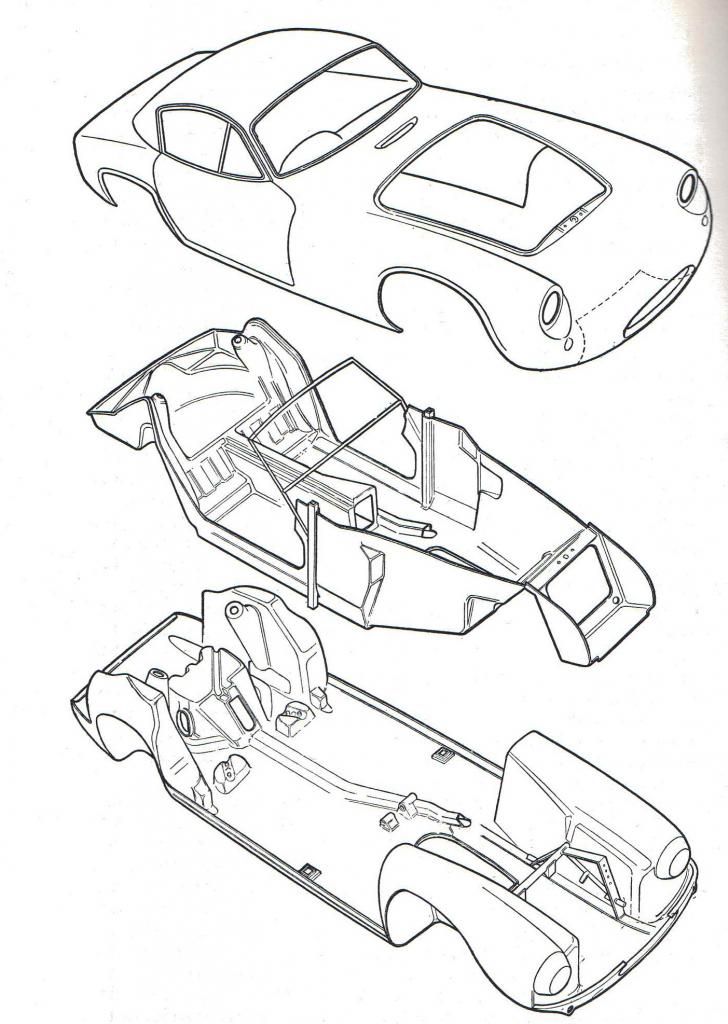

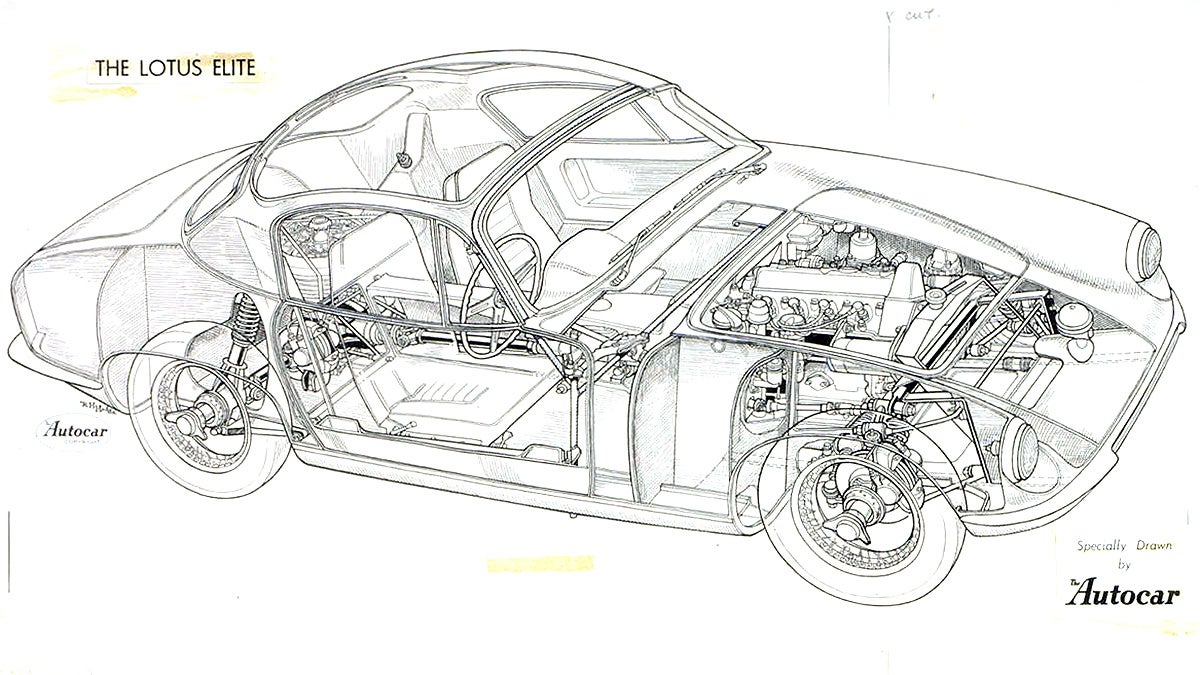

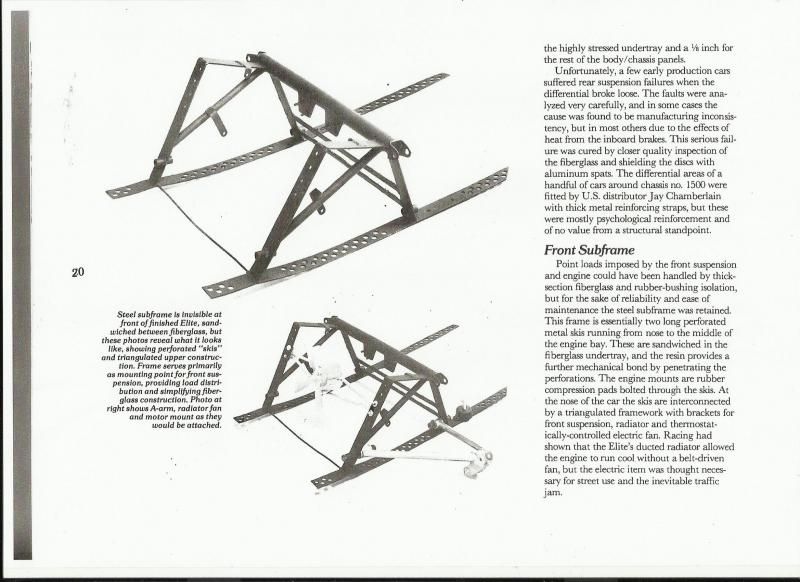

By 'Lotus Elite Series 1', I assume we are talking about the Type 14 Elite?

The 'skis' of the suspension subframe are bonded to the lower moulding of the monocoque.

These images may help:

|

|

|

Volvorsport

|

| posted on 5/9/14 at 01:42 PM |

|

|

Exactly what I was looking for , theres not much in thd way of suspension pick ups

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

Sam_68

|

| posted on 5/9/14 at 01:53 PM |

|

|

quote:

Originally posted by Volvorsport

...there's not much in the way of suspension pick ups

It's a Lotus. There's not much in the way of anything!

It's actually quite an elegant and minimalist structure, as you'd expect. Remember that the Elite is an almost 60 year old design, though,

for a 1200cc engine producing not more than about 95bhp... the concept would need beefing up a bit for modern power outputs, brakes and tyres!

This pic may also be useful in illustrating how the suspension bolts to the subframe a bit more clearly - though it only shows the bottom wishbone,

not the upper transverse link or the ARB that acts as the other link in the upper 'wishbone':

[Edited on 5/9/14 by Sam_68]

|

|

|

Volvorsport

|

| posted on 5/9/14 at 02:05 PM |

|

|

I take it those are scanned copies from a book ?

it is an elegant design really , it looks as though two parts of the chassis were bonded together , then the body dropped onto that ?

I was just thinking that a modern engine producing 95 hp would be quite small and light , and easily affordable .

although I was gonna drop a 5 cyl into my sylva striker bodywork and build the chasiis around it , another madcap project ..

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

Sam_68

|

| posted on 5/9/14 at 02:25 PM |

|

|

quote:

Originally posted by Volvorsport

I take it those are scanned copies from a book ?

The first and last images are. The cutaway and the photo of the subframe are courtesy of Google (though I think the cutaway is also shown in Costin

and Phipps).

quote:

Originally posted by Volvorsport

...it looks as though two parts of the chassis were bonded together, then the body dropped onto that ?

All three main mouldings are bonded together - the outer bodyshell is a stressed part of the monocoque as well, not merely cosmetic.

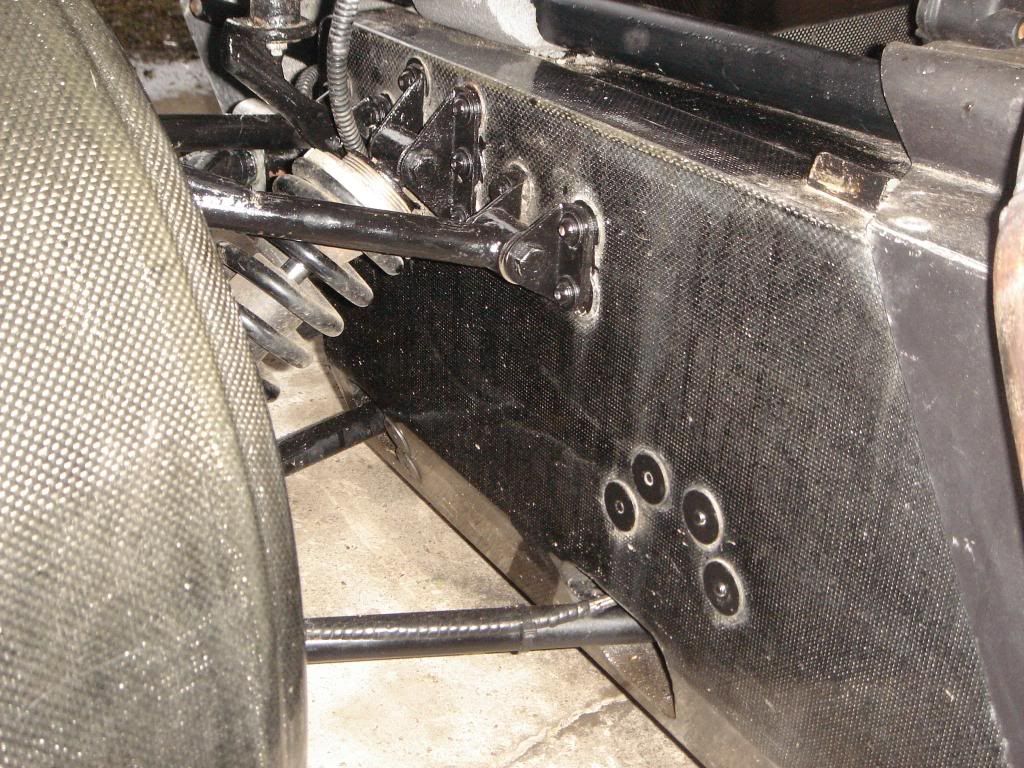

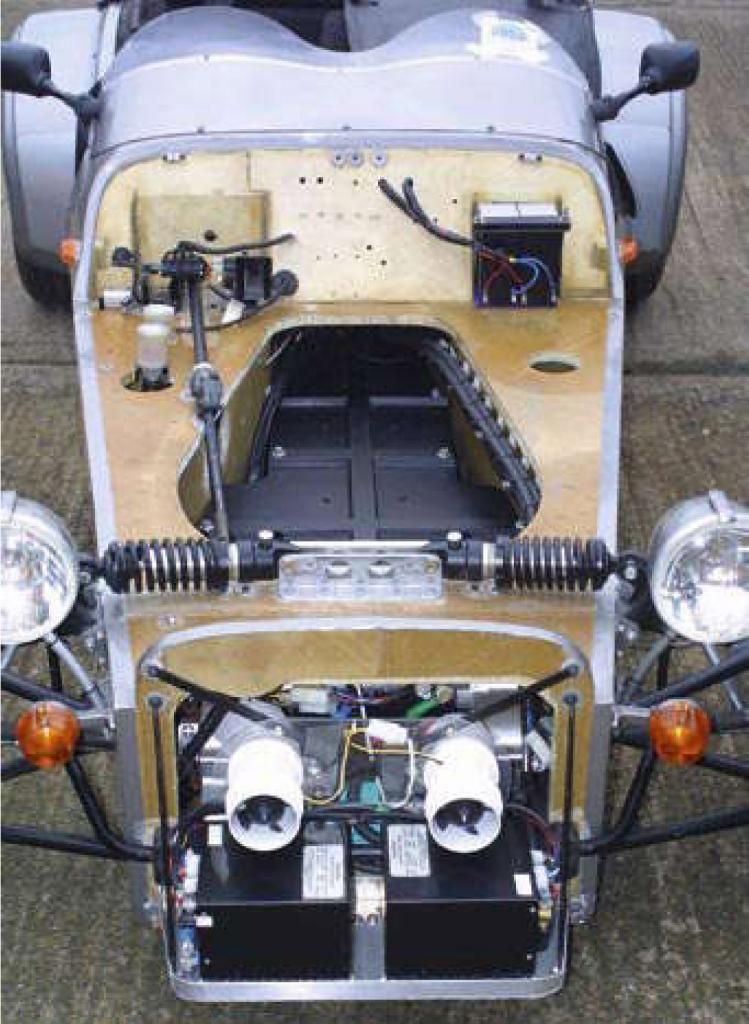

If you're thinking about doing similar, these days, have a look at the way my old FW400 did it, with separate brackets mounted by multiple

bobbins into a carbon-skinned honeycomb sandwich panel (Cellite, effectively):

|

|

|

Volvorsport

|

| posted on 5/9/14 at 02:36 PM |

|

|

One way to do it, itd be more expensive that way

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

Sam_68

|

| posted on 5/9/14 at 02:49 PM |

|

|

quote:

Originally posted by Volvorsport

One way to do it, it'd be more expensive that way

Much quicker and simpler, though; you don't have to use carbon-skinned Cellite unless you want it for bling value - the E-glass skinned panels

are almost as effective in practice - and you can rout-and-fold the panels, rather than messing about with laying up, vac-bagging and autoclaving

complicated mouldings.

For a one-off or small production run, and if you factored in even a small cost for your own time, it would actually work out much cheaper,

I'm sure.

|

|

|

Volvorsport

|

| posted on 5/9/14 at 05:19 PM |

|

|

I cant buy just one sheet tho ..... Teklam wanted 800 dollars for an 8x 4 sheet. Grp is much cheaper . It was certainly my first idea to use grp

backed honeycomb

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

Sam_68

|

| posted on 5/9/14 at 06:52 PM |

|

|

Yes, the price per sheet is high but if you are are careful with the design of a chassis for a small car, you don't need many sheets. And, as

per my previous response, you don't have the monumental costs in labour (and a surprisingly high cost in materials, too, once you add

everything up) that you have with a moulded wet layup. It will also give you a much better stiffness:weight ratio than a moulded, predominantly

non-sandwich GRP tub like the Elite or GTM Libra

Cellite 620 (with epoxy glass skins) is about £260 ($425?) per 8'x4' sheet, and there are companies who will happily sell you a single

sheet (and give you a discount for larger orders).

Martin Ogilvie's WiSPER ('Westfield in Structural Plastics Electric Roadster' ) used epoxy glass skinned panels, rather than carbon

fibre:

If you think that even e-glass pre-manufactured sandwich panels from Teklam or Cellite are exorbitant, you could always use the approach that Lotus

used with one of the first (along with the McLaren MP4/1) carbon monocoque F1 cars - designed, like the FW400 and WiSPER, by Martin Ogilvie - which

was to manufacture their own carbon honeycomb panels using a flat sheet of glass as the 'mould', then fabricate the tub using

rout-and-fold techniques.

But by the time you've factored in all the equipment costs (sheet glass of sufficient thickness ain't cheap, vac-bagging equipment

you can manufacture yourself from a dead fridge, but again remember to factor in a cost for your time) and materials costs (carbon or glass fabric,

epoxy resin, honeycomb materials, release agents, breather plies for de-bulking, bagging film, etc.), and figured out that your quality control

isn't going to be a patch on the professionals, prices for Cellite don't look too bad to me.

I've been slowly developing a design (admittedly using some very novel techniques to keep costs down) that would allow me to commercially

manufacture (ie. including labour costs) small runs of tubs using honeycomb sandwich composites at a price that is competitive with steel

spaceframes... it can be done, you just need to take a Lotus-like approach to ruthless simplification of the design.

|

|

|

Volvorsport

|

| posted on 5/9/14 at 07:21 PM |

|

|

I think we think the same when it comes to this type of chassis manufacture....

do you know the mosler mt900 chassis at all ? Very simple.

i have some ideas on a modern fwd chassis if your interested.

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

Sam_68

|

| posted on 5/9/14 at 07:53 PM |

|

|

quote:

Originally posted by Volvorsport

do you know the mosler mt900 chassis at all ? Very simple.

I can't say that I do, and the best image I could find with a quick Google was this one, but yes, it looks relatively straightforward:

It looks as if it requires steel subframes front and rear, though, which partly defeat the advantages of a composite tub?

It looks not too dissimilar in concept to the Tornado GT40 replica carbon tub, though that mounts the front suspension to the tub and only uses a

subframe at the rear:

The Mosler looks as if it uses bonded mortice-and-tenon 'tabs' to join some of the panels? Quick and easy, but I must admit I have a bit

of a 'thing' about leaving the exposed edge of the honeycomb visible where you use this technique, as appears to be the case on the

Mosler's bottom panel.

The Strathcarron/Javan tub was similar but even simpler, though I really don't like some of the detailing on it and the basic structural design

looks very questionable, with the unbraced, open tops to the bays:

quote:

Originally posted by Volvorsporti have some ideas on a modern fwd chassis if your interested.

I'm always interested in new chassis or suspension ideas, though FWD isn't really my thing, and I'm afraid I can't reciprocate

much in terms of my own current designs - I'm now deep into the realms of non-disclosure to protect possible future patent applications.

|

|

|