Fred W B

|

| posted on 9/6/05 at 05:52 AM |

|

|

Connecting Rover V8 engine to a Audi 016 transaxle for CANAMSA

I'm finally starting to make some concrete progress in my quest to bolt a Rover V8 engine to a Audi 016 transaxle.

I started with this forged blank (once the design and drawing of the required part was finished):

BLANK

Okay, that is a huge billet (dia 400mm x 90 mm thick = 90kg), but is was donated.

|

|

|

|

|

Fred W B

|

| posted on 9/6/05 at 05:55 AM |

|

|

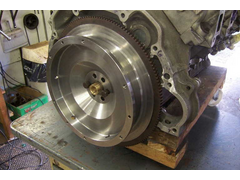

Went to see a mate with a CNC machine centre, large lathe etc. 2 days later, picked up this.

FLYWHEEL BACK

The finished part is dia 300 mm x 64 mm thick, weighed 7 kg (without ring gear).

|

|

|

Fred W B

|

| posted on 9/6/05 at 05:57 AM |

|

|

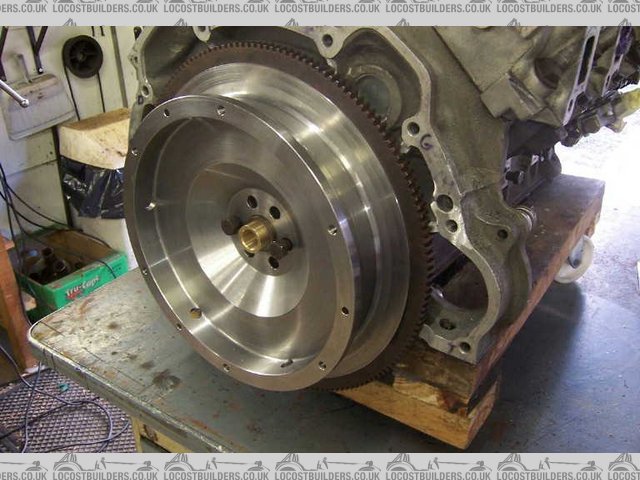

Which fits like this:

FLYWHEEL FRONT

I have positioned the ring gear closer to the engine than on the standard Rover, to the extent of having to relieve slightly some of the casting webs

on the back of the block.

|

|

|

Fred W B

|

| posted on 9/6/05 at 06:00 AM |

|

|

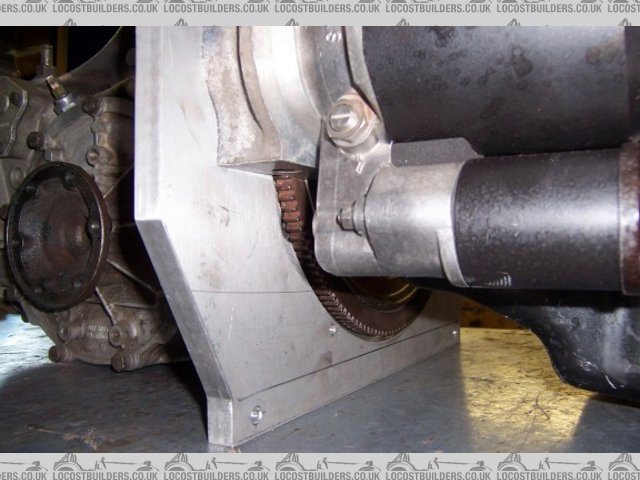

Now I just have to make this:

PLATE

This is the the (final) prototype adaptor plate, machined in supawood to confirm the hole positions before I have the real one cut from aluminium. To

keep the adaptor plate down to a thickness of 16 mm, the ring gear will run in the recess in the thickness of the adaptor plate.

I will update as further progress is made.

Cheers

Fred WB

PS - Should this rather have been posted in the "Engine and Transmission section?

|

|

|

garage19

|

| posted on 9/6/05 at 08:50 AM |

|

|

I love people that engineer their way round a problem... no matter what.

Looks great.

|

|

|

mangogrooveworkshop

|

| posted on 9/6/05 at 10:19 AM |

|

|

quote I love people that engineer their way round a problem... no matter what.

Being a South African and has little choice but to do it.

He also has good engineering culture that will do what you ask. Come to Scotland and we have to pull teeth to do anything a little differant for a

million pounds charge.

|

|

|

chrisf

|

| posted on 9/6/05 at 01:17 PM |

|

|

That is unbelievable!

--Chris

|

|

|

tadltd

|

| posted on 9/6/05 at 01:33 PM |

|

|

Not if you come to us! You can walk away with a one-off part and your teeth intact!! (unless you've been on the Irn-Bru too much...). We can now

provide CNC machined components to your spec' - one-off, prototype, low volume, etc.

Excellent job Fred, good to see you're making significant progress.

Best Regards,

Steve.

www.turnerautosport.com

|

|

|

ned

|

| posted on 9/6/05 at 04:37 PM |

|

|

Great progress Fred, but may I ask how much that flywheel weighs? I presume it's steel and not ally?

Ned.

beware, I've got yellow skin

|

|

|

Fred W B

|

| posted on 9/6/05 at 06:55 PM |

|

|

Ned, you muppet, look under the 2nd picture

"The finished part is dia 300 mm x 64 mm thick, weighed 7 kg (without ring gear)."

No offence meant

It is steel.

Thanks for kind words guys.

Just picked up a 1000mm x 500mm x 16 mm plate of 6082 T6 alloy at bargin price of R35 (UKP 2.8) a kilo, so keepin up the momentum

Cheers

Fred WB

|

|

|

tadltd

|

| posted on 9/6/05 at 07:26 PM |

|

|

I thought it looked a bit hefty too, Ned! But obviously not. Still, at least I avoided being called a muppet for once in my life!

If it was me, tho' I'd have had a lot more holes drilled in it!!!

[Edited on 9/6/05 by tadltd]

[Edited on 9/6/05 by tadltd]

Best Regards,

Steve.

www.turnerautosport.com

|

|

|

Rorty

|

| posted on 10/6/05 at 04:30 AM |

|

|

Excellent, well thought out bit of old fashioned engineering there Fred. That's the way things were done before forums and high disposable

incomes.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Fred W B

|

| posted on 10/6/05 at 05:47 AM |

|

|

Forgot to mention that the original rover flywheel weighs 14 kg

The wall thicknesses of all areas of the new flywheel are mostly 6 mm, with the conical centre section 8 mm thick.

Cheers

Fred WB

[Edited on 10/6/05 by Fred W B]

|

|

|

Rorty

|

| posted on 10/6/05 at 06:05 AM |

|

|

Fred, here's a slightly clearer version of your avatar if you'd like it:Image deleted by owner

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

Fred W B

|

| posted on 10/6/05 at 08:50 AM |

|

|

Thanks Rorty, avatar now changed. It does look better.

Cheers

Fred WB

|

|

|

ned

|

| posted on 10/6/05 at 09:26 AM |

|

|

hands up to that one, must stop skim reading

imho 7kg is quite god for what you've got there, well done. i suppose the clutch will bring hte weight up, but as you rightly say it will be

lighter than the original so will aid the speed the engine can spin up nicely..

Ned.

beware, I've got yellow skin

|

|

|

violentblue

|

| posted on 10/6/05 at 09:59 PM |

|

|

hmmm, very impressed.

How much to have another one of those done up? I have a buddy who would like to stick a rover V8 in his Europa.

a few pics of my other projects

|

|

|

Fred W B

|

| posted on 23/10/05 at 08:30 AM |

|

|

To finally finish the story, here is the finished alloy adaptor plate, looking from the engine side. It is 16 mm thick, with an 8 mm recessed area for

the flywheel. The large countersinks are for the plate to trans attachment bolts.

[img][/img]

|

|

|

Fred W B

|

| posted on 23/10/05 at 08:32 AM |

|

|

Here you can see 3 x M6 countersinks that are tapped into the engine to locate the plate, and the trans attachment bolts in position

[img][/img]

|

|

|

Fred W B

|

| posted on 23/10/05 at 08:35 AM |

|

|

Plate to engine bolts and clutch fitted. One trans bolt only just cleared the RV8 starter motor, with the head cut off on one side. The slots in the

ends of the trans bolts are to hold the bolts with a screwdriver while you run the nuts up.

clutch

|

|

|

Fred W B

|

| posted on 23/10/05 at 08:38 AM |

|

|

Here you can see one of 3 spring pins that locate the trans on the plate.

[img][/img]

|

|

|

Fred W B

|

| posted on 23/10/05 at 08:41 AM |

|

|

Complete assembly bolted up

drive train

|

|

|

Fred W B

|

| posted on 23/10/05 at 08:44 AM |

|

|

Trans case relieved to clear starter motor

[img][/img]

|

|

|

Fred W B

|

| posted on 23/10/05 at 08:47 AM |

|

|

Fit of ring gear in plate. You can also just about see the countersunk head of one of the trans bolts, opposite the nut on the starter solenoid bolt

ring clear

Cheers

Fred WB

|

|

|

skint scotsman

|

| posted on 23/10/05 at 09:11 AM |

|

|

so simple yet so affective

well done fred

|

|

|