NS Dev

|

| posted on 29/3/06 at 11:34 AM |

|

|

sprung to unsprung weight ratio

looking around on't web re. another thing and found this which explains nicely what I am always wittling on about re spring rates and dampers on

out little cars:

"The Ratio of Sprung to Unsprung Weight

Unsprung weight includes the mass of the tires, brakes, suspension linkages and other components that move in unison with the wheels. These components

are on the roadway side of the springs and therefore react to roadway irregularities with no damping, other than the pneumatic resilience of the

tires. The rest of the mass is on the vehicle side of the springs and therefore comprises the sprung weight. Disturbances from the road are filtered

by the suspension system and as a result are not fully experienced by the sprung weight. The ratio between sprung and unsprung weight is one of the

most important components of vehicle ride and handling characteristics.

Unsprung weight represents a significant portion of the total weight of the vehicle. In today's standard-size automobile, the weight of unsprung

components is normally in the range of 13 to 15 percent of the vehicle curb weight. In the case of a 3,500 pound vehicle, unsprung weight may be as

high as 500 pounds. A 500 pound mass reacting directly to roadway irregularities at highway speeds can generate significant vertical acceleration

forces. These forces degrade the ride, and they also have a detrimental effect on handling.

Early pioneers believed that the primary job of the suspension system was to absorb bumps and smooth out the ride. Today we understand that an equally

important function of the suspension is to keep the tires in contact with the road. This is not as easy as it might appear to be. When a tire

encounters an irregularity the resulting forces tend to reduce contact pressure and therefore degrade adhesion. Obstacles impart a vertical

acceleration to tires that increases in proportion to the forward speed of the vehicle and the size of the obstacle. The greater the accelerated mass

(unsprung weight) the greater the kinetic energy. In a sense, a raised obstacle throws tires away from the roadway. A depression causes the surface to

rapidly drop away leaving the tire to follow along when inertia can be overcome by the downward pressure of the springs. Both occurrences reduce the

tire's contact-pressure and tires can actually become airborne if the forces are great enough.

The forces generated by roadway irregularities (bumps) must be overcome by the springs in order to keep tires in contact with the road. The force of

the springs comes from the compressive load imposed by the weight of the vehicle. The lighter the vehicle, the less compressive force is available,

and the easier it is for the vertical motion of the wheels to overcome the inertia of the sprung mass and transfer motion to it as well. The ideal

combination occurs when the ground pressure is maximized and inertial forces are minimized by a high sprung-to-unsprung weight ratio. A high ratio

keeps the tires more firmly in contact with the road, and it also produces the best ride.

The sprung-to-unsprung weight ratio is particularly important to the design of extremely low mass vehicles. The necessarily higher suspension

frequency produces a rougher ride, which can be accentuated by smaller tires typical of smaller cars. Smaller diameter tires react more violently to

bumps and potholes. Their reduced radius causes them to move deeper into depressions and climb more quickly over obstacles. The higher acceleration

rates are offset to a large degree by the reduced mass of the smaller tires. Tests have shown, however, that smaller tires do in fact produce a

rougher ride, even though they are lighter. With smaller, lighter vehicles, it is even more important to keep the ratio of sprung to unsprung weight

as high as possible in order to reduce the undesirable effects of smaller tires. "

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

|

|

Hellfire

|

| posted on 29/3/06 at 11:53 AM |

|

|

Does the percentage of 13 to 15 apply to our types of vehicle as well then?

What spring rates (front and rear) would you recommend for a ~500kg seven?

I know all vehicles differ, as does their intended useage but what, in your opinion, is the recommended rates?

|

|

|

Liam

|

| posted on 29/3/06 at 12:13 PM |

|

|

We took my mates old live axle blade engined westy down the local weighbridge and it came out at 430kg. Totting up the weight of the live axle, heavy

hubs brakes wheels etc etc and you come out closer to 50% unsprung mass!! Kind of explains why the ride was so bad on anything bumpy. Softer springs

would definately help but the fundamental problem is such a high unsprung to sprung ratio. Live axle definately aint good for a BEC.

Most locosts i've been in ride really badly over bumps. You can hear them bounce and rattle and the rear axle hop all over the place. Went for

my first ride in a caterham a while ago and have to admit i was stunned by the ride. I didn't think it would be possible for a seven to be so

good over bumps! The springs were definately very soft (and damping well matched) as I noticed loads more suspension travel and body movement than in

any locost (i guess that's why caterhams have an ARB). Nevertheless it rode bumps like my Jag, stuck like glue and didn't make a single

bang, shake or rattle. I concluded most locosts i've been in are hugely oversprung/damped and totally agree with all the people trying to point

this out.

Liam

|

|

|

Bob C

|

| posted on 29/3/06 at 12:22 PM |

|

|

I have a simple take on this -

Spring rates are slightly reddish herring in this discussion... a 500kg car will have (say) 125kg force pushung down on each tyre regardless of spring

rate!

A smaller car has less downward force keeping the tyre on the deck - so it must have less unsprung weight in order to maintain the same level of

contact on a rough surface.

GB roads count as a rough surface! Race tracks are often much smoother so you see lots of racers doing OK with live axles & heavy wheels.

Spring rates do other things - roll stiffness, natural oscillating frequency; & dampers are tuned to the springs/sprung mass system.

cheers

Bob

|

|

|

Bob C

|

| posted on 29/3/06 at 12:26 PM |

|

|

BTW I tried quite hard to keep my unsprung weight down - IRS, ally calipers & disc bells, lightish wheels - I average 30kg a corner. That's

25%

ouch!

Bob C

|

|

|

NS Dev

|

| posted on 29/3/06 at 12:34 PM |

|

|

.................and as an agricultural rule of thumb statement, the worse the ratio, the more you need to spend on

dampers................................

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

NS Dev

|

| posted on 29/3/06 at 12:41 PM |

|

|

quote:

Originally posted by Hellfire

Does the percentage of 13 to 15 apply to our types of vehicle as well then?

What spring rates (front and rear) would you recommend for a ~500kg seven?

I know all vehicles differ, as does their intended useage but what, in your opinion, is the recommended rates?

bit tricky, needs a combination of experience and theory, and depends on whether priority is track days or road driving.

My 7 is mainly for road driving so needs to be compliant, and will be at the high 500 kgs, maybe nearer 600kg (vaux XE engine)

on that I have 140lb rear springs and 275 lb front springs. I have a feeling I may need to amend that to 150 rear and 260 front but that's suck

it and see.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

02GF74

|

| posted on 29/3/06 at 12:53 PM |

|

|

quote:

With smaller, lighter vehicles, it is even more important to keep the ratio of sprung to unsprung weight as high as possible in order to reduce

the undesirable effects of smaller tires. "

well I'm not into spring rates and complex stuff like that but knew that you want to keep unsprung weught as low as possible; basically all of

the article, include the quoted bit above reworded.

|

|

|

Fred W B

|

| posted on 29/3/06 at 03:02 PM |

|

|

Again, I may regret this...

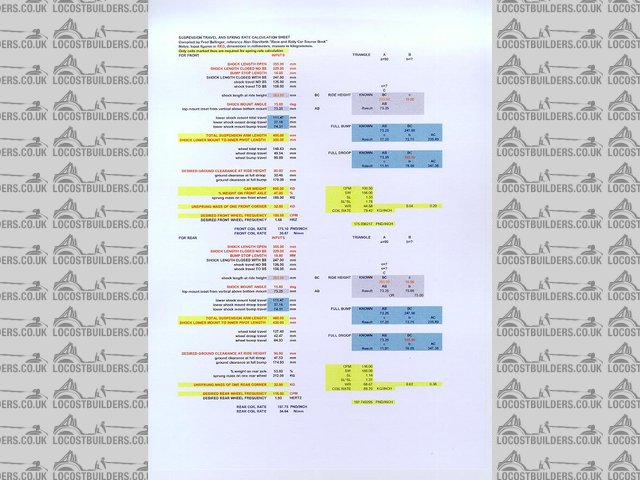

As far as I can see, in order to compare anything, you need to quote wheel frequency. On this, I subscribe to the gospel according to Staniforth, like

this

rates

Feel free to mail me if you would like the spread sheet.

Cheers

Fred WB

|

|

|

Liam

|

| posted on 29/3/06 at 04:27 PM |

|

|

quote:

Originally posted by Fred W B

Again, I may regret this...

As far as I can see, in order to compare anything, you need to quote wheel frequency. On this, I subscribe to the gospel according to Staniforth, like

this

I agree. Spring rates cant really be compared accross different weight cars with different suspension geometry. Wheel frequency is where it's

at. Mine is designed to be adjustable between 80 and 120 cycles per minute on the front and about 90 - 130 on the rear. According to staniforth that

ranges from a sporty road car up into the sort of frequencies racers use (for those trackdays  ). Yet it seems soft and compliant to me, again

suggesting a lot of locosts i've tried are running crazy wheel rates. ). Yet it seems soft and compliant to me, again

suggesting a lot of locosts i've tried are running crazy wheel rates.

liam

[Edited on 29/3/06 by Liam]

|

|

|

gingerprince

|

| posted on 29/3/06 at 04:39 PM |

|

|

If the ratio is the important factor, then just put a big bag of lead in your passenger seat. sprung weight goes up, ratio comes down

|

|

|

NS Dev

|

| posted on 29/3/06 at 05:07 PM |

|

|

If you can't get the ratio better by reducing unsprung weight (as is commonly the case on the rear of a 7) then moving weight to that end of the

car can help, not quite adding lead but not far off!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

cymtriks

|

| posted on 29/3/06 at 10:04 PM |

|

|

The book givs-

Front 210lbs 90cpm

Rear 190lbs 133cpm

This implies a very stiff rear suspension.

A softer setting could be-

Front 210lbs 90cpm with anti roll bar

Rear 120lbs 106cpm

Those figures are in the same ball park as the Elise (90cpm front 98cpm rear) and McLarenF1 (85cpm front and 105cpm rear)

|

|

|

WIMMERA

|

| posted on 29/3/06 at 10:56 PM |

|

|

I've heard a suspension guru quote 10:1 sprung/ unsprung as a target figure, hard to achieve in a clubbie though, a few locals are going to

inboard brakes at the rear and spending vast sums on lightweight wheels and tyres in an attempt to get somewhere near it.

Wimmera

|

|

|