clockwork

|

| posted on 7/5/07 at 05:51 PM |

|

|

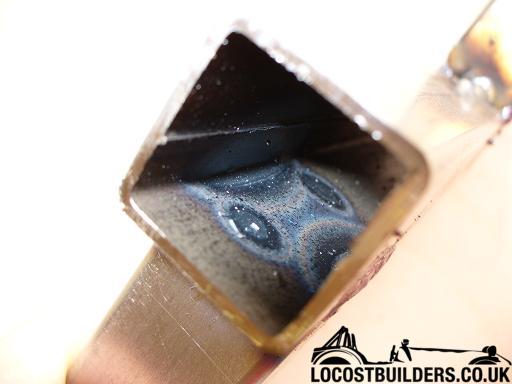

Welding penetration part II

Clarke 151 TE 0.8mm wire, 1.8mm RHS

Following on from part 1 I went and took some pictures

Which is best (I think I know the answer)?

1>>

2>>

3>>

4>>

5>>

Sorry if the above is a bit much; my last post was a bit underinforming, so I went for overkill this time

[Edited on 7/5/07 by clockwork]

|

|

|

|

|

arrybradbury

|

| posted on 7/5/07 at 06:01 PM |

|

|

Apologies - i posted none of the above due to not knowing anything about welding and not wanting to spoil the results from people who do know

|

|

|

blakep82

|

| posted on 7/5/07 at 06:05 PM |

|

|

^ then don't vote! just click show results, or however its worded on here just click show results, or however its worded on here

i shall keep an eye on this thread though, see what the results are

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

oadamo

|

| posted on 7/5/07 at 07:10 PM |

|

|

i seen a lot of welding qs on here ill see if i can make a vid at work using a welding lens on my camera and ill post a link. a sort of how to guide

with mig steel and tig steel alloy and stainless

adam

|

|

|

Dantheman

|

| posted on 7/5/07 at 07:21 PM |

|

|

A bit off topic but I'm planning on getting a welder soon and had the model you mentioned in mind. Can it be run from a normal wall socket?

BTW, 5 looks best to me.

|

|

|

clockwork

|

| posted on 7/5/07 at 07:37 PM |

|

|

yes but no plugs supplied and you need a 13 amp fuse as well

|

|

|

Mansfield

|

| posted on 7/5/07 at 08:41 PM |

|

|

I am a long way off an expert but it looks like you have not got a good enough view of the welding or you are not supporting the torch very well.

If you search through all the 'how to weld' threads on here you will find a 9 lens is always recommended. I have not tried this yet but

apparently you can see where to start with a 9 lens if you light the workpiece with a strong light.

My welding improved significantly once I could see what I was up to (even though I thought I could to start with). I also found I needed less heat

once I had more control of what was happening.

You are certainly getting the penetration, the neatness will come. It took me a lot of practice, but I sort of get it now. Good thick gloves also

help no end.

Edit - I added 'thought I' to '(even though I could to start with)' which makes much more sense.

[Edited on 7/5/07 by Mansfield]

|

|

|

Mansfield

|

| posted on 7/5/07 at 08:45 PM |

|

|

PS I quite like 5, I think 4 would have been better if you were pointing the torch more towards to the across bit of the T, the end of the down bit of

the T heats up a lot quicker.

|

|

|

907

|

| posted on 7/5/07 at 08:55 PM |

|

|

Like you say, you know anyway.

You need a tad of build up on the outside. (convex weld profile)

and a tad of even penetration.

Just as important is that the weld should roll round the corner at both the start and finish of the weld.

This will make it easy to join onto when welding the remaining sides.

Looks like your starts are sometimes a little off the mark.

Try to be more accurate in where the wire is pointing when you first pull the trigger.

Full marks BTW on your attitude to welding and your desire to get it right.

HTH

Paul G

O, number 5 btw.

|

|

|

Mark Allanson

|

| posted on 7/5/07 at 08:59 PM |

|

|

1 and 2 are a bit light on penetration, 3 and 4 have a bit of undercut (creates stress risers), and 5 is not bad.

Bit more accuracy with the torch and an EW9 is def recommended.

To be fair, all are good enough to hold a locost together.

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

mark chandler

|

| posted on 7/5/07 at 09:24 PM |

|

|

5 for me.

IMHo it looks to me like you need to practice weaving more, gentle C's maybe to improve shape.

It also looks like you are doing this with a free hand, have you a decent helmet or one of those handheld job's ?

If you use an auto helmet you can support your welding wrist with the other hand, this greatly improves control which will help both you start and

finishes.

As above all will hold a Locost together, good effort, no nasty bird droppings in sight.

Regards Mark

|

|

|

Mansfield

|

| posted on 7/5/07 at 09:25 PM |

|

|

Mark, thanks for seconding the EW9 recommendation but I would like to say that it was your recommendation in the first place, it makes a world of

difference.

I did find improvement in my technique by doing long runs along lengths of steel rather than 1" wide joints, it was almost over before it

started. By doing some 6" runs you can get a feel for torch speed and settings and have time to appreciate what is going on. Once you can

control the straight bits you can concentrate more on the (probably more difficult and more important) start and end bits.

|

|

|

ScotJebus

|

| posted on 7/5/07 at 09:42 PM |

|

|

The pratice runs on a flat bit of plate will help you a lot, but on the shade recomendation, through college the shades that are recommned by the time

served teachers are 10 or 11, and getting started needs pratice but once you get the nack you'd wonder how you messed it up before. And

definatly steady you welding arm with your free arm it makes it so much easier.

|

|

|

Mark Allanson

|

| posted on 7/5/07 at 09:58 PM |

|

|

quote:

Originally posted by mark chandler

5 for me.

IMHo it looks to me like you need to practice weaving more, gentle C's maybe to improve shape.

It also looks like you are doing this with a free hand, have you a decent helmet or one of those handheld job's ?

If you use an auto helmet you can support your welding wrist with the other hand, this greatly improves control which will help both you start and

finishes.

As above all will hold a Locost together, good effort, no nasty bird droppings in sight.

Regards Mark

Sorry Mark, but you don't weave with a MIG unless you are stitching up 5mm plate upwards. Weaving will only put the focus of penetration over a

wider area. You need a DEAD straight pass of exactly even speed and angle, on 16g I use exactly 90° torch angle. The weld is only 1" at its

longest, and the start and finish of the welds are the weakest, so in theory you should start mid tube and go around the corner in one pass so only 2

passes per tube - worth thinking about

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

robertst

|

| posted on 7/5/07 at 10:02 PM |

|

|

quote:

Originally posted by Mark Allanson

To be fair, all are good enough to hold a locost together.

I LOVE THIS MAN! these are the sort of optimistic remarks that make you keep on going and not throw the towel at the first instant of frustration!....

sorry... i suppose its clockwork that should be saying this...

by the way, my favourite are weld 5 and weld 1. weld 3 has a huge weld pool and not enough penetration but at still that is better than a narrow pool

and pores, unwelded areas, etc...

[Edited on 7/5/07 by robertst]

Tom

|

|

|

clockwork

|

| posted on 7/5/07 at 10:03 PM |

|

|

Thankyou all for your comments, can't believe how many people are on here this evening!

I'm very surprised at the variance in the poll responses . . . it is a bigger spread than I was expecting that's for sure.

I was given an auto-darkening helmet for nowt, but can't really see too well through it. I've gone back to my "old" (also

free) permanent dark helmet, but I think y it's a bit too dark. Unfortunately I have no idea what strength the lens is.

With regard to where I started the welds, the reason the welds are off at the start is I didn't clamp the metal prior to starting (I will do it

properly later), so started on one of the peices and moved over once the pool had started.

oadamo, thanks for your offer on the video, I found one online here, but it is rather short.

I have tried doing nice long runs but, to be honest, it's much easier and the welds look neat, but you are right I need to roll the tip at the

edges more.

Personally I reckon 5 was the best (of a bad bunch), and the reason I stopped, as I think 907 noticed ;-)

I would be interested to see how the poll continues . . . so please keep polling.

Anyway, at the very least I need to practice a bit more. I have to say, I thought the welding was going to be the least fun part of the build, but

I'm having a great time welding bits of cr*p together!

Thankyou all.

Michael

|

|

|

robertst

|

| posted on 7/5/07 at 10:10 PM |

|

|

welding is by far my favourite part of the build! shame i've finished that stage

useful tip: i also have that manual, permanent dark helmet and it takes time getting used to coordinate your left hand which operates the visor

and the right hand which operates the electrode  if you happen to come across many of those "oops, forgot to put the visor down"

moments and u get sore eyes (not the best of experiences i can tell u), remember that a wet potato on each eye at the end of the day works a treat! if you happen to come across many of those "oops, forgot to put the visor down"

moments and u get sore eyes (not the best of experiences i can tell u), remember that a wet potato on each eye at the end of the day works a treat!

[Edited on 7/5/07 by robertst]

[Edited on 7/5/07 by robertst]

Tom

|

|

|

Mark Allanson

|

| posted on 7/5/07 at 10:23 PM |

|

|

Building the chassis was one of my most enjoyable parts too, but as an ex welder/fab, it was all done in less that a week, shame the rest took over 2

years

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

ken555

|

| posted on 7/5/07 at 10:29 PM |

|

|

Video

In the video the wire speed is gradually increased from very slow to very fast. The comments at the top show where I think the wire speed is too slow,

good, and too fast.

Be sure to turn your sound on - the sound of the weld reveals what is happening. There's a control at the bottom of the video you can move to

listen again to each segment.

Video taken from here

[Edited on 7/5/07 by ken555]

|

|

|

907

|

| posted on 7/5/07 at 10:30 PM |

|

|

Take your lens out and clean it. Replace the clear one if it's the slightest bit opaque.

Spectacle cleaner is good.

For clarity you can't beat glass (IMHO)

The shade number should be on your dark lens. i.e. EW10 near the edge or corner.

Paul G

|

|

|

Mark Allanson

|

| posted on 7/5/07 at 10:34 PM |

|

|

If in doubt, the weld should sound like frying bacon!

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

desyboy

|

| posted on 11/6/07 at 06:28 PM |

|

|

quote:

Originally posted by Mark Allanson

If in doubt, the weld should sound like frying bacon!

And not frying sausages.

|

|

|

Mark Allanson

|

| posted on 12/6/07 at 09:47 PM |

|

|

Sausages are at least a half octave below bacon, this IS a precision craft!

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

NS Dev

|

| posted on 13/6/07 at 11:59 AM |

|

|

Number 5, wouldn't be too chuffed with the others.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

Peteff

|

| posted on 13/6/07 at 06:47 PM |

|

|

if you happen to come across many of those "oops, forgot to put the visor down" moments

Get some tinted glasses to wear under the visor, it's the UV that burns your eyes and even plain glasses will help stop it.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|