Which glue to join alu panels to chassis?

MadMaxx - 30/10/21 at 07:49 PM

Hi,

I heard to use Sikaflex to join alu panels to chassis before to rivet them, but wich one?

Sikaflex 117? Sikapower 4720 with 20 times more strenght to add torsional rigidity? Others?

Many thanks in advace for any tips.

Mike Wood - 31/10/21 at 07:31 AM

There will be a range of recommendations on here and some useful old discussion threads.

A common suggestion is Sikaflex 221: https://www.merlinmotorsport.co.uk/p/black-sikaflex-221-polyurethane-adhesive-sealant-pur-bk (manufacturerís data

sheet: https://gbr.sika.com/dms/getdocument.get/8445dc23-8053-4492-b52c-9409a50064cb/sikaflex-221.pdf )

Some previous threads on the topic (there may be more): http://www.locostbuilders.co.uk/viewthread.php?tid=36074

https://www.locostbuilders.co.uk/viewthread.php?tid=207985

One from Locost USA website with some interesting thoughts: https://www.locostusa.com/forums/viewtopic.php?f=23&t=11916

Cheers

Mike

[Edited on 31/10/21 by Mike Wood]

[Edited on 31/10/21 by Mike Wood]

[Edited on 31/10/21 by Mike Wood]

[Edited on 31/10/21 by Mike Wood]

[Edited on 31/10/21 by Mike Wood]

[Edited on 31/10/21 by Mike Wood]

mcerd1 - 31/10/21 at 01:16 PM

If you've got a Wurth shop near you (there seems to be one in Bergamo) then this stuff is pretty good too:

https://eshop.wurth.co.uk/Product-categories/Bond-and-Seal-structural-adhesive/31083005041106.cyid/3108.cgid/en/GB/GBP/

and as a bonus its only £7.30 each inc VAT  (I have to assume its a similar price where you are too)

(I have to assume its a similar price where you are too)

its the stuff that Dax used and loads of other vehicles too (inc holding the panels on train carriages)

[Edited on 31/10/2021 by mcerd1]

[Edited on 31/10/2021 by mcerd1]

jacko - 31/10/21 at 01:24 PM

Any pu glue type sealers I glue new panels on buses and we use tiger pu but as above there are lots of different makes make sure it has pu on the

tube

Jacko

Ps put gloves on donít get it on your hands if possible to smooth it use soppy water

[Edited on 31/10/21 by jacko]

MadMaxx - 31/10/21 at 02:00 PM

Thanks to all for your helpfull tips. I think the best solution could be the PU from Wurt that I can buy next to my home

nick205 - 1/11/21 at 09:53 AM

Always strikes me that bonding panels to a "painted" chassis must be largely down to how well the paint is adhered to the chassis. The

panel adhesive could be stuck massively well to the paint, but the paint may simply "peel" off the chassis!

mcerd1 - 1/11/21 at 10:29 AM

^^ I'm sure the OE manufacturers have to take that into account somehow...

but this is why for most car like ours its recommended to strip back and key the contact surfaces

nick205 - 1/11/21 at 11:04 AM

quote:

Originally posted by mcerd1

^^ I'm sure the OE manufacturers have to take that into account somehow...

but this is why for most car like ours its recommended to strip back and key the contact surfaces

Fair point if builders strip and key the surfaces, but I suspect most don't - it would be a pain to re-paint neatly after the panels are bonded

in place.

I think for most builders / cars the adhesive element will provide a water seal (OK if you have a full screen and weather gear). Aside from that the

mechanical hold of the rivets will hold the panels in place and provide any torsional strength.

snapper - 1/11/21 at 11:48 AM

quote:

Originally posted by nick205

Always strikes me that bonding panels to a "painted" chassis must be largely down to how well the paint is adhered to the chassis. The

panel adhesive could be stuck massively well to the paint, but the paint may simply "peel" off the chassis!

Having recently tried to strip off a badly painted inlet plenum I can say that most paint will not strip off in the manner that wall paper would,

powder coating may strip off partially but this is usually due to corrosion under the powder coat and if bare metal was corroded prior to gluing that

would definitely cause issues, so make sure your chassis is prepared properly for bonding on panels.

MadMaxx - 1/11/21 at 12:22 PM

quote:

Originally posted by snapper

quote:

Originally posted by nick205

Always strikes me that bonding panels to a "painted" chassis must be largely down to how well the paint is adhered to the chassis. The

panel adhesive could be stuck massively well to the paint, but the paint may simply "peel" off the chassis!

Having recently tried to strip off a badly painted inlet plenum I can say that most paint will not strip off in the manner that wall paper would,

powder coating may strip off partially but this is usually due to corrosion under the powder coat and if bare metal was corroded prior to gluing that

would definitely cause issues, so make sure your chassis is prepared properly for bonding on panels.

I send blasted chassis before powder coat it, even if not corroded at all. It is a new chassis that I realised to replace the original one that was

bent and with several cracks, so I'm expecting a good adehesion of the powder coat.

Regarding torsional rigidity, I don't expect a great contribution by the bonding, because the PU adesives are elastic. But if there's a good

adehesion there will not infiltration of water inside the tubes and no rattle. I will relay on rivets, to increase torsional rigidity as well as some

triangulation added to the original chassis design.

Mr Whippy - 1/11/21 at 12:42 PM

Really in this case it's the rivets that are limiting how much strength your getting not the glue. For the glue to contribute the rivets would

have to be deforming which they won't unless you crash, in which case stronger glue might be nice

If you were considering crash worthiness then maybe look at some of the newer structural adhesives used on most modern cars rather than windscreen

stuff as they are amazingly strong and sometimes the metal fails before the glue. However most of these I've looked at do require a very tight

panel fit and super clean surfaces, which rules out most of my applications...

mcerd1 - 1/11/21 at 12:54 PM

^^^ keying the bond area is still a good idea

you only need to remove the paint / coating up the centre of the where the PU is going to go (I needed a flap wheel as my powder coat was really well

stuck on  ) the idea being that the adhesive should squish out a little and overlap with the remaining powdercoat / paint to seal it all up - no

touch up required if your careful

) the idea being that the adhesive should squish out a little and overlap with the remaining powdercoat / paint to seal it all up - no

touch up required if your careful

also keying the alloy or GRP panels - again just rough them up in the area where the glue will be only (I test fitted the panels then scribed lines

round the edges of the tubes to keep it neat - then just be careful with the course emery paper)

this way the PU is probably doing most of the actual work - the rivets are probably just clamping it while the adhesive cures (but they do also

provide a good secondary mechanical fixing just encase)

also if you are comparing different PU adhesives you'll see that some are much stiffer when cured than others:

the Wurth bond & seal stuff I linked to above is great for high strength and pretty stiff too - its similar properties to Sikaflex221

something like tiger seal is much softer and weaker, but good for bonding in brittle things like glass (also harder to find any proper data on as its

more of a consumer product than the others)

don't take that to mean I don't also have rivets in mine though.... 've just got a few

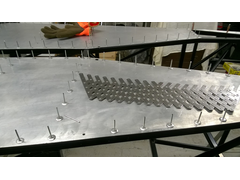

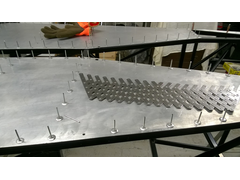

compulsory floor panel pic

my new favourite tool

floor on !

[Edited on 1/11/2021 by mcerd1]

mcerd1 - 1/11/21 at 01:16 PM

also I should add that I treated myself to a few 'skin pins' and a big (cheap) bag of cleco's too - they make it so much easier

when your pre-drilling the panels - as soon as you have a couple of holes done and pinned (say one each end) the panel can't go anywhere - no

alignment issues ever again

Description

Description

this way its dead easy to pre-drill everything and scribe the edge of the tubes on the panels - then take the pins out knowing it will all go back

perfectly once its stripped back, the glue is on and you start the rivets...

like these but you can probably shop around for better deals, but these seem to be a good price just now:

https://www.lasaero.com/products/article/O0273HUC5

https://www.lasaero.com/products/article/X01A0QWGL

then next step if your feeling lazy like me is some kind of powered rivet gun...

[Edited on 1/11/2021 by mcerd1]

MadMaxx - 2/11/21 at 11:18 AM

PU glue will be good also to glue big heads fixing to the fiberglass of body or rear of the alu dashboard or is it necessary to use e more specific

glue, like two components resins?

mcerd1 - 2/11/21 at 01:38 PM

quote:

Originally posted by MadMaxx

PU glue will be good also to glue big heads fixing to the fiberglass of body or rear of the alu dashboard or is it necessary to use e more specific

glue, like two components resins?

it would defiantly stick them and I'd think it would be fine for most low stress things like that

(thats not to say there isn't a stronger way, but that will depend on what you do with it and the area you have for the glue)

The dax rush uses this type of PU adhesive to stick the front wings on - no bolts (but a good key and lots of PU and lots of clamping) - and I

don't know anyone thats had issues with them...

cliftyhanger - 11/11/21 at 07:05 AM

quote:

Originally posted by jacko

Ps put gloves on donít get it on your hands if possible to smooth it use soppy water

[Edited on 31/10/21 by jacko]

I have been using Everbuild PU40 as a car seam sealer for years, and recently using it to seal showers in student houses. Doesn't go mouldy,

doesn't lift, but importantly it seems to be OK and stick even if the little buggers have not left the shower dry for the previous 12hrs (yes I

do dry it, but there is always a bit of water lurking)

But my point is simple.

If you want to clean PU adhesive, or silicon, off hands or surfaces, buy some cheap (tesco value etc) baby wipes. Somehow they work as long as the

sealant is fresh. Goodness knows how, I guess it is the weave if the wipes as they don't seem to have any serious detergents/solvents. But they

are absolute magic.

(I have to assume its a similar price where you are too)

(I have to assume its a similar price where you are too)