Mr Whippy

|

| posted on 4/9/23 at 11:53 AM |

|

|

They look very good but I suspect that normal PLA will not cope with the heat from the brakes as wheels can get quite hot.

|

|

|

|

|

Stot

|

| posted on 5/9/23 at 04:20 PM |

|

|

quote:

Originally posted by Mr Whippy

They look very good but I suspect that normal PLA will not cope with the heat from the brakes as wheels can get quite hot.

Quite right. I only made one for testing, the plan was to mould, cast and paint some if I liked them. I decided I liked the look of the car without

them better in the end but it was a good challenge designing them to print in one piece.

To be honest even PETG reaches its glass point in/on a car very easily. I made

cup holders for my Range Rover at the time and

they loosened up from shrinking slightly in the heat.

Cheers

Stot

|

|

|

tims31

|

| posted on 10/9/23 at 12:32 PM |

|

|

quote:

Originally posted by christim

Yes! It's a game changer especially for custom builds

As above, PLA is no good because of the heat. I'm using PETG which turns out fine on my Ender 3 S1

So far I've made a mount for the idle air control valve to go onto the plenum:

Draft in PLA

Final in PETG

Now I could do with one of those for mine. Is that a GBS plenum and how is it mounted to the plenum? Cant quite tell from the pictures?

Build: http://www.martinsfurybuild.co.uk/

|

|

|

Mr Whippy

|

| posted on 11/9/23 at 06:35 AM |

|

|

quote:

Originally posted by Stot

quote:

Originally posted by Mr Whippy

They look very good but I suspect that normal PLA will not cope with the heat from the brakes as wheels can get quite hot.

Quite right. I only made one for testing, the plan was to mould, cast and paint some if I liked them. I decided I liked the look of the car without

them better in the end but it was a good challenge designing them to print in one piece.

To be honest even PETG reaches its glass point in/on a car very easily. I made

cup holders for my Range Rover at the time and

they loosened up from shrinking slightly in the heat.

Cheers

Stot

One trick with PLA to make parts more resistant to heat if using 100% infil, is to boil the part in water for about 10 mins, the parts shrink about

5%, so just scale up to compensate. I've used this making electric motor mounts and works well, they are definitely stronger and last much better

when heated. I wonder if the same process would work on PETG to prevent the part changing dimensions later in use?

|

|

|

christim

|

| posted on 11/9/23 at 08:33 AM |

|

|

quote:

Originally posted by tims31

Now I could do with one of those for mine. Is that a GBS plenum and how is it mounted to the plenum? Cant quite tell from the pictures?

Yep GBS Plenum, mounted with bolts going through into the plenum. I got the idea from this blog

(richards-gbs-zero.blogspot.com)...same principle but 3d printed and

a hole to add a hose connector:

My Build Thread

|

|

|

tims31

|

| posted on 11/9/23 at 09:20 PM |

|

|

quote:

Originally posted by christim

quote:

Originally posted by tims31

Now I could do with one of those for mine. Is that a GBS plenum and how is it mounted to the plenum? Cant quite tell from the pictures?

Yep GBS Plenum, mounted with bolts going through into the plenum. I got the idea from this blog

(richards-gbs-zero.blogspot.com)...same principle but 3d printed and

a hole to add a hose connector:

That looks ideal, does it work well? On mine I have just the throttle body cracked open but it sits at around 1300 to1500 rpm and it drives me mad.

Where do you tap the hose off to, is it on your intake line?

Could you post a couple of close up pictures too so I can see how you have mounted it please?

[Edited on 11/9/23 by tims31]

Build: http://www.martinsfurybuild.co.uk/

|

|

|

christim

|

| posted on 14/9/23 at 05:10 PM |

|

|

That looks ideal, does it work well? On mine I have just the throttle body cracked open but it sits at around 1300 to1500 rpm and it drives me mad.

Where do you tap the hose off to, is it on your intake line?

Could you post a couple of close up pictures too so I can see how you have mounted it please?

Yeah it's solid, and free air flowing...no issues. I've just updated my build diary so some extra pics of the overall setup there. but

here's some close up's of the part. It's got gasket sealant between it and the plenum, and a cardboard gasket between it and the valve.

The inlet is a threaded pipe connector that threads into the part, used thread locker there so it's not budging:

Hope that helps!

My Build Thread

|

|

|

christim

|

| posted on 14/9/23 at 05:15 PM |

|

|

quote:

Originally posted by Stot

quote:

Originally posted by Mr Whippy

They look very good but I suspect that normal PLA will not cope with the heat from the brakes as wheels can get quite hot.

Quite right. I only made one for testing, the plan was to mould, cast and paint some if I liked them. I decided I liked the look of the car without

them better in the end but it was a good challenge designing them to print in one piece.

To be honest even PETG reaches its glass point in/on a car very easily. I made

cup holders for my Range Rover at the time and

they loosened up from shrinking slightly in the heat.

Cheers

Stot

Interesting. I'm hoping to make some front upright dust caps (for a Sierra uprights they are now non-existent!) Shouldn't be too hot there

but will keep an eye on them given the above

My Build Thread

|

|

|

tims31

|

| posted on 14/9/23 at 08:32 PM |

|

|

quote:

Originally posted by christim

Yeah it's solid, and free air flowing...no issues. I've just updated my build diary so some extra pics of the overall setup there. but

here's some close up's of the part. It's got gasket sealant between it and the plenum, and a cardboard gasket between it and the valve.

The inlet is a threaded pipe connector that threads into the part, used thread locker there so it's not budging:

Hope that helps!

Thanks for that. Yeah has given me some ideas for mine. I'll have a look at trying to design something for mine and see if I can get it 3d

printed, or even make me take the plunge and get one for the bits I want to do.

Build: http://www.martinsfurybuild.co.uk/

|

|

|

christim

|

| posted on 14/9/23 at 09:20 PM |

|

|

I can send over the .stl file if you do get a 3d printer. Or happy to print one out if not. Send me a u2u if you want either

My Build Thread

|

|

|

Mr Whippy

|

| posted on 15/9/23 at 11:09 AM |

|

|

quote:

Originally posted by christim

I can send over the .stl file if you do get a 3d printer. Or happy to print one out if not. Send me a u2u if you want either

You can save the files on thingiverse for others to use for free or even Cults 3D if you want to make some money from them. I save quite a few things

I design and it's amazing how many do download them.

|

|

|

Mr Whippy

|

| posted on 15/9/23 at 11:48 AM |

|

|

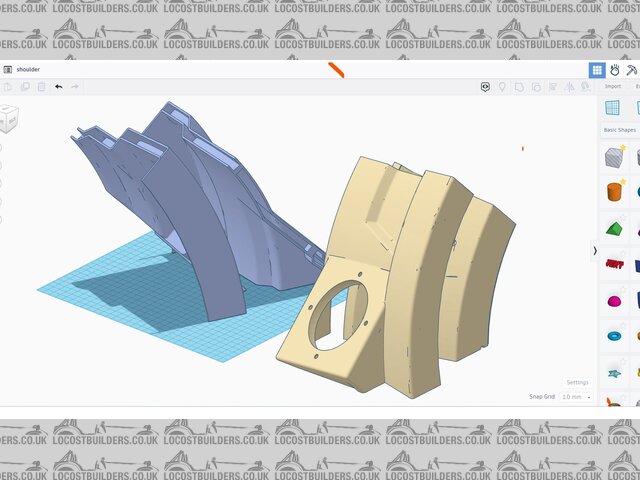

Don't underestimate free software like Tinkercad, once you learn how to use it, it's actually quite powerful, plus because it is web based

it will run on some very basic machines like my little budget laptop which could not even run blender without freezing! I did try sketchup which I

liked, apart from I would then had to pay over £200 for the pro version just to save STL files, so went back to Tinkercad.

Tinkcad also has a lego & minecraft model generators, real time electronics designer/simulator and programming in code

Description

[Edited on 15/9/23 by Mr Whippy]

|

|

|

Stot

|

| posted on 15/9/23 at 11:55 AM |

|

|

I use Fusion 360, they still have a free tier that's fine for hobby use, main limitations are you can only have 10 'active' projects at

a time and some CNC cut path stuff is missing.

The active project thing isnt an issue either because you can activate and deactivate projects at will.

Cheers

Stot

|

|

|

coyoteboy

|

| posted on 15/9/23 at 11:57 AM |

|

|

FWIW I tried many different CAD packages, I never got on with Blender/Freecad/Tinkercad, or OnShape, because I've been a bit spoilt with Fusion

360/NX/Solidworks/Catia in work but I did then find you can get a Maker license for Solidworks for 100 quid a year, which only requires that you

don't make more than 2000$ per year profit. I've been using that for 2 years now and apart from the usual gripes about Solidworks stability

(my machine is fully certified workstation with an i7 6 core and 32 gig of ram and a Quadra M4000 certified graphics card, but it still crashes at

times). Well worth it if you're just making your own bits and bobs, sending stuff off to workshops.

You can save all locally (I disabled the cloud saving nonsense) and get CAM etc for 3 axis no problem.

https://discover.solidworks.com/3dexperience-solidworks-makers

[Edited on 15/9/2023 by coyoteboy]

|

|

|

Mr Whippy

|

| posted on 15/9/23 at 02:58 PM |

|

|

My point was if you don't have fancy cad software or even a powerful machine or don't fancy learning how to use it all, you can do some

quite advanced design work for 3D printing using some of the free online tools such as Tinkercad, which I have had great success with.

|

|

|

christim

|

| posted on 15/9/23 at 03:16 PM |

|

|

I learnt on Sketchup back when Google owned it. Still use it now & does exactly what I need it to. (it's web based now which I can't get

on with...still have the programme on my PC and I use that)

I did wonder about uploading...the things I've designed are very niche (see above) and I can't see a huge call for them. Maybe I should

rethink and upload them!

My Build Thread

|

|

|

coyoteboy

|

| posted on 15/9/23 at 03:50 PM |

|

|

quote:

Originally posted by Mr Whippy

My point was if you don't have fancy cad software or even a powerful machine or don't fancy learning how to use it all, you can do some

quite advanced design work for 3D printing using some of the free online tools such as Tinkercad, which I have had great success with.

I know what your point was 😊. I was just adding the point that the free ones are often hard and long to learn and there's cheap

non-free commercial options. 👍

|

|

|