Bluemoon

|

| posted on 11/12/09 at 03:41 PM |

|

|

quote:

Originally posted by blakep82

like this

Description

you're right, i didn't mean less will flow, but it won't flow as easy.

normally the pump will be pumping water up as fast as its coming down, gravity will help keep water moving up. and no real effort on the pump

with too much air the pump willbe pumping against gravity also

[Edited on 11/12/09 by blakep82]

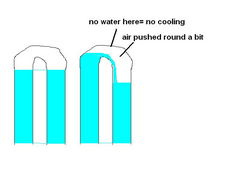

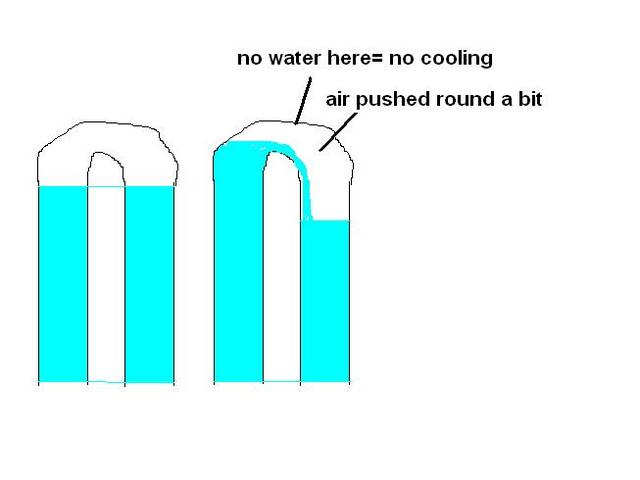

The above picture has it in one, the only time water would not flow is when the pump can't lift it higher than the U. i.e. imagine the pump has

to lift the water from the level condition, to the one where it's lifted up high enough to "fall" over the U that requires the pump to

build up pressure. Thus a pump will have some upper pressure that it can't exceed so the water would stop flowing with a sufficient height.

I guess any extra pressure requirement from this air gap probably also slows the flow (as the pump has to work to move the water as the bubble of air

is there). Thus reducing the cooling efficiency. Without the air in the U no pressure difference would be needed to create the flow and the pump will

flow the largest amount fluid it can.

Like others have said an airlock in the thermostat housing is bad news, as it will never open as the thermostat not warm up.. You would know this is

happening though as the rad would not get warm..

Dan

[Edited on 11/12/09 by Bluemoon]

|

|

|

|

|

Steve G

|

| posted on 11/12/09 at 03:50 PM |

|

|

The air bubble always rises to the highest point. Blow against it and you are blowing against that bouyancy for want of a better word - you are trying

to force the bubble through the tube and it naturally wants to return to the highest point

|

|

|

02GF74

|

| posted on 11/12/09 at 04:47 PM |

|

|

quote:

Originally posted by Findlay234

Do you actually have an issue where an 'air lock' is actually restricting flow or are you trying to hypothetically understand it?

no and yes.

let's say it is crossflow thermostat housiing, and we can approximate this to the u-bend above.

let's also say that there is ari above the termostat and that there is no small hole in the thermostat.

in normal situation, there is water above hte thermostat.

engine warms up, the water below the thermostat in which the valve is immersed opens and water flows to the radiator.

now let's say the is air above the thermostat.

how is it going to be different.

like before, no water flows due to thermostat being closed. as before once the wax gets hot enough the valve will open. now the situation is

different as there is air above the thermostat.

I cannot believe that water will not flow past the air.

convince me otherwise.

|

|

|

Bluemoon

|

| posted on 11/12/09 at 05:50 PM |

|

|

Arrr the thermostat is in the airlock, it has not warm water around it only air.. Then it will probably not open as the thermostat is cooled by the

surrounding metal, the conduction of air is poor compared with water (other wise we would use air to cool the engine rather than water)..

This is why the hole (or bypass flow in some cases) is important, as lets the air out and ensure the thermostat is always submerged (particularly on

the hot side)... The hole also allows a small flow of hot engine coolant to ensure the thermostat is around the same temperature of the engine..

Dan

[Edited on 11/12/09 by Bluemoon]

|

|

|

Nash

|

| posted on 11/12/09 at 06:22 PM |

|

|

OK think of it like this:

At Cold start up in the Thormostat housing the stat is closed. The water warms up and opens the stat and the water flows. The stat opens because the

water is getting hotter and hotter due to it NOT flowing. It doesn't open due to pressure build up. OK so far?

Now in the case of the Air Lock the flow is restricted or completely blocked. If I read you correctly you think the pressure will build and eventually

move the air? Well two things prevent that:

1. The water will take the path of least resistance and water will move elsewhere not allowing pressure build up

2. The pump will not build pressure as its not a positive displacement pump. Its a constant velocity pump so the water just circulates around the

gears (it takes the path of least resistance around the pump casing)

So the pressure never increases and the air isn't forced to move. The flow stalls and the engine overheats.

Hope that helps?

..........Neil

[Edited on 11/12/09 by Nash]

It's What You Do Next That Counts.

Build It, Buy It, Drive It:

Southern Kit Car Club

|

|

|

jollygreengiant

|

| posted on 11/12/09 at 06:33 PM |

|

|

The problem here is that you think in two dimension instead of three. You are thinking purely in terms of water OR air. With a cooling sytem ther is a

third dimension and that is of the the hot intermediate state of water, STEAM.

Once you have an air lock develop, then you have a surface which is NOT cooled. This surface then gets very hot and any water that makes contact with

the uncooled areas perifery will almost certainly turn to steam thus increasing volume and thereby uncooled area of engine internals.

What annoys me about some manufacturers is that if you look closely at some cooling systems then they expect water and air not follow the laws of

physics, some designers expect air to flow down through water when you look at the hose arrangement, (some rovers spring to mind)

Beware of the Goldfish in the tulip mines. The ONLY defence against them is smoking peanut butter sandwiches.

|

|

|

Toltec

|

| posted on 11/12/09 at 07:58 PM |

|

|

Interesting thread.

Thinking about how air could restrict flow -

Archimedes principle tells us that the upthrust generated by the air is equal to the mass of the volume of water it displaces. The pump is trying to

move all of the contents of the system, the air effectively pushes back against the pump.

Imagine a column of water mixed with air where the water flow is downwards and just sufficient to keep the air bubbles circulating in an approximately

static region. At any particular point in the pipe the area of the pipe available for fluid flow is reduced by the cross sectional area of all of the

bubbles at that point.

Fluid dynamics is obviously rather more complex and there will be further losses, however just taking the two above it is easy enough to see that air

will cause a loss of flow.

The other thing I did not notice any mention is that the pressure in the system is not even throughout it. The pressure in the head/block is much

higher than the radiator etc. There are flow restrictors at the water exits from the head that help keep the pressure much higher to prevent boiling

around the exhaust ports. Not sure what difference this makes, I suspect the higher pressure would make air bubbles easier to shift since they should

be smaller.

|

|

|

hoots_min

|

| posted on 11/12/09 at 08:05 PM |

|

|

Here's my tuppence.

Water will naturally contain a certain amount of air which will vary dependent upon temperature - the hotter the water, the more air will be contained

within it. This is why you will have more air present int the system when it is cold and why it is better to bleed the air out when it is cold.

Having air in your system be it pressurised or non-pressurised will ultimately result in a reduction of cross sectional area available for flow.

Taking the upside down U bend as example, the pressure at both sides of the air bubble will be virtually equal, the only difference being that the

upstream side will be ever so slightly higher to overcome the frictional pressure drop of the water through the pipeline. As a result the bubble may

move ever so slightly forward but the pressure difference will be very small (we are talkin millibars here as there are only very short distances

involved). The air bubble will therefore not move under steady state conditions (i.e. stable flow).

As mentioned above also, the presence of the air will result in a drop off in flow. This is a result of the cross sectional area (CSA) that is taken

up by the air bubble. Think of it as a natural restriction, i.e. 1" pipe then going into a ½" pipe and then back to a 1" pipe.

Reducing the CSA by half actually increases the pressure drop in that section by 32!! (the DP is related to 1/dia^5). So you therefore get a drop off

in flow because of the presence of the air; if the bubble is present in a section downstream of a split, then flow will preferrentially favour the

path of least resistance.

Under steady flow, the bubble will not move. However, if you are able to create a differential across the bubble, for example create a vacuum or a

large pressure on one side, the bubble will move. The 'incompressible' nature of water means it can produce a 'water hammer'

effect when a pump is started up which may push the bubble along if it is close enough to the pump, but after the tortuous route the water generally

has to go through, the energy from the pressure wave will likely have dissipated.

(I write 'incompressible' in apostrophes as there may be some out there who argue that water is compressible. To a degree it is and

compressibility factors are readily published, however, at the pressures we are discussing here, it can be regarded as incompressible.)

hope this helps.

Today is a good day: I achieved new heights of ineptitude.

|

|

|