Mix

|

| posted on 2/1/06 at 11:29 PM |

|

|

I'm with Jono on the wirelocking issue.

Loss of torque can arise in a nuber of ways, bolt streaching, fretting of the joint, corrosion are three that spring to mind. It has always been my

understanding that the function of locking wire was to retain the fastener in the event of a loss of torque and thus preventing 'catastrophic

failure' which may occur if the fastener falls out completely, (or in the case of aircraft, if an unrestrained fastener interferes with a

critical component)

Mick

|

|

|

|

|

RichieC

|

| posted on 2/1/06 at 11:35 PM |

|

|

Yep, but when tension is applied in the direction of tightening, and of course done correctly, said wire will prevent the fastener from rotating in

the other direction. It physically cannot rotate as it would be pulling the other bolt head tighter if it tried to.

Were not talking about locking the bolts to something else like a hole but to each other, thats the difference.

I was an aircraft technician in a previous incarnation and in the numerous examples Im thinking of, items were locked to prevent them loosening, not

to prevent them falling out, if it had got to that stage, you were already in the catostrophic failure you talk about.

Rgds

Rich

|

|

|

RichieC

|

| posted on 2/1/06 at 11:41 PM |

|

|

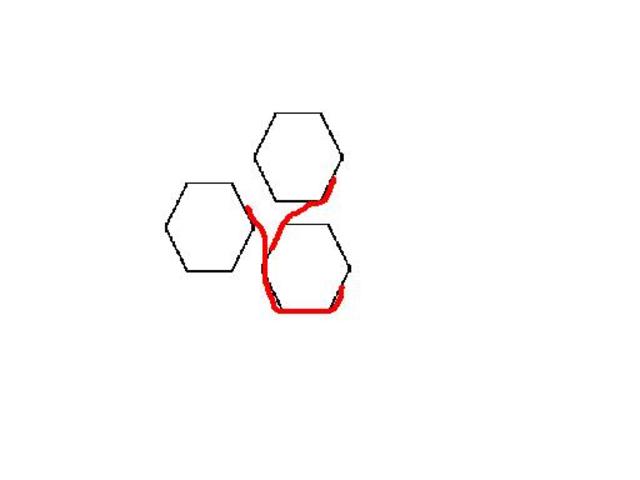

Hope my dodgy paint skills explain it better, Ive used an example of just 3 bolts but the same principle applies.

Fingers crossed I didnt anti lock them but its getting late

Each of the bolts are being pulled clockwise and cannot rotate anti clockwise (assuming conventional threads).

All of this asside, it shouldnt be required; it wasnt for Ford, but for piece of mind it would help. I dont see how you could go wrong with the right

bolts, fitted with the right spready thingies (for belt and braces) torqued up correctly.

Rgds

Richie

[Edited on 2/1/06 by RichieC]

Rescued attachment Locking Wire.JPG

|

|

|

Stu16v

|

| posted on 3/1/06 at 12:58 AM |

|

|

quote:

Originally posted by Mix

I'm with Jono on the wirelocking issue.

Loss of torque can arise in a nuber of ways, bolt streaching, fretting of the joint, corrosion are three that spring to mind. It has always been my

understanding that the function of locking wire was to retain the fastener in the event of a loss of torque and thus preventing 'catastrophic

failure' which may occur if the fastener falls out completely, (or in the case of aircraft, if an unrestrained fastener interferes with a

critical component)

Mick

Lockwiring *is* there to retain the fastener in the event of loss of torque. But if you remove the reason behind the 'loss of torque', you

don't need lockwiring. Ford didn't need it, why should we? IMHO prepare the surfaces properly, tighten correctly, add loctite to the

equation if required, and there won't be a problem...

Dont just build it.....make it!

|

|

|

NS Dev

|

| posted on 3/1/06 at 09:06 AM |

|

|

Exactly!

|

|

|

smart51

|

| posted on 3/1/06 at 10:45 AM |

|

|

When I reassembled the car yesterday I found that it is a bit more fail safe than I thought. The nose of the shaft sits in the cup of the stub axle

and so won't fall out, even if the bolts all come out.

|

|

|

NS Dev

|

| posted on 3/1/06 at 11:16 AM |

|

|

In a similar vein, on the grasser I don't run circlips on the shafts.

The shafts have slightly rounded noses (not std sierra shafts, custom made ones) and the splines are 4" long at each end.

The shafts are then free to slide through the CV's at each end which gives more available travel, and they cannot escape from the cv's at

each end of the travel as they are retained by the cups.

|

|

|

RichieC

|

| posted on 16/1/06 at 06:04 PM |

|

|

Just an update for anyone whos interested, the banana shaped lock plates are still available from Ford at about a quid a piece.

I cannot see how 12.9 grade bolts with these and a spot of loctite could come loose, "belts and braces".....and a piece of string maybe

Rgds

Rich

[Edited on 19/1/06 by RichieC]

|

|

|

RichieC

|

| posted on 19/1/06 at 06:04 PM |

|

|

Locking Plate part number is F1018715

£0.95p each + VAT

Rgds

Richie

|

|

|