nitram38

|

| posted on 2/2/09 at 10:54 PM |

|

|

There will be arguements forever on this one!

Suspension is a compromise because in the real world, limiting factors like space and available materials are imposed.

Also, when you improve one area of design it normally causes a detrimental change in another area.

Whatever you build, I can guarantee that you will find the limit.

Instead of arguing who is the better designer, try actually doing something and get out there and drive the dam thing!

|

|

|

|

|

Delinquent

|

| posted on 5/2/09 at 03:26 PM |

|

|

quote:

Originally posted by nitram38

Suspension is a compromise because in the real world, limiting factors like space and available materials are imposed.

Also, when you improve one area of design it normally causes a detrimental change in another area.

When my Dad started designing his scratch build, his approach to the suspension was to take front and rear setups from two completely different

vehicles, and bolt them in a place to give the correct wheelbase.

I've seen people visibly grimace when I've told them that - "you can't do that, x y and z, the c of g, it can't work the

car weighs half as much, the roll centres are all wrong for each other blah blah blah.

You know what - the steering is light but responsive, and it grips the road. The tyres don't wear oddly, but you get plenty of feedback, and the

aerodynamics of the car put pay to it's ability waaay before the suspension does...

Fluke, or just acceptance that the 101 compromises in suspension will for the most net a similar result.

|

|

|

cheapracer

|

| posted on 16/2/09 at 09:50 AM |

|

|

It's all a compromise. If you want a good starting point, work on your roll line and trail, they are the biggies and both often overlooked and

the roll line is often not even mentioned.

A roll line is the line drawn between the 2 RC's - thinking along these lines (pun intended) will help you to see things clearer.

Scrub radius is one of the most talked about load of crap out there probably through the wheel industry out of the mouths of mag wheel

countersalesmen. It does very little in the real world and if I used wheel spacers, I will take a bit of steering feedback with the better handling

from the wider track any day of the week.

Scrub radius is easy to adjust through wheel offset or wheel spacers and with McPherson struts. changing the top strut mount in or out.

One note is that zero scrub can be bad if you have compliance in the suspension because you can suffer from sign change and that can upset a car.

(positive scrub on one side and neg srub on the other at the same time).

Note that not all that many years ago, cars had up to 4" of scrub radius (and no one was dying).

Kurt said it well, if your getting good even tyre wear your probably close to ideal all round geometry.

It's coming....

|

|

|

cheapracer

|

| posted on 16/2/09 at 09:55 AM |

|

|

Just a note, go to a historic race meeting and watch the 60's sedans, terrible suspension, bad geometry, live rear axles etc. and yet see how

they go around corners with MODERN TYRES and SHOCKS - thats the secret.

It's coming....

|

|

|

kb58

|

| posted on 16/2/09 at 04:22 PM |

|

|

For that matter, look how the new 4000 pound(!) Nissan GTR goes around corners. It's amazing what good tires and suspension can do in spite of

all the weight. (and 4WD and 480hp, and...)

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

v8kid

|

| posted on 7/3/09 at 07:10 AM |

|

|

I approached it slightly differently.

My reasoning is that the tyre contact patch is the most important thing so the tyre choice should be first. Suprisingly there is not such a big choice

of tyres out there! and I ended up with - yes you guessed it 13" rims. At this point the use of the car is cast in stone

Next by my logic was to get the most out of the tyre contact patch and that means loading them as evenly as possible - basic physics tells us that

this means the Cofg must be as low as possible. In turn this determined my engine and gearbox choice (dry sump and gearbox input shaft higher than

driveshaft outputs)

I wanted to get the best braking I could and reckoned that to be 50/50 front/rear at 1.5g (might as well be ambitous!) and coupled with the expected

Cofg height that gave my target weight distribution.

Wheel rate choice is a fairly standard procedure see Stanniforth et al.

Roll stiffness distribution was a puzzler untill a kind soul on Engtips pointed me in the right direction and after 6 months I managed to produce a

spreadsheet that should work

Tyre width choice is a minefield I dont know how to solve it. My first stab at it was way too conservative and resulted in clouds of smoke at every

standing start. Tried and trusted method is to copy others and watch tyre temps - must be a better way!

I totally ignored roll centers and just concentrated on keeping the camber right under all variations of roll/braking/acceleration using SLARK and my

spreadsheet above. Mark Ortiz was very helpfull and I even understood what he was saying this time! Guess what? Yup the geometric roll centeris

static. Spookey or what!

Of cource practicality jumps up and smacks you in the nose now and again I'm now on my third gearbox rebuild due to some extremely bad advice

but on the bright side I know a lot more about 'boxes now!

Sounds easy don't it but it has taken me 3 years to get this far and at times it drags.

Cheers All

David

|

|

|

rpmagazine

|

| posted on 9/4/09 at 11:51 AM |

|

|

so, time flies...how is the project v8kid?

www.racemagazine.com.au

|

|

|

v8kid

|

| posted on 9/4/09 at 12:32 PM |

|

|

Slower than I hoped RPM I'm sprinting my wife's shopping car this season so I guess that says it all.

I got well and truly ripped off with the gearbox by both the UN1 "specialists" in the UK and it has been a constant weakness despite

splashing out on quaiffe internals and "new" parts.

Hopefully it will be finally fixed this month. Curently I'm learning about the mysteries of tyres and am finding it most instructive.

The only high spot is the engine which is absolutely superb I highly reccommend Ian Richardson at Wildcat Engineering

How goes the roadcar project?

[Edited on 9-4-09 by v8kid]

|

|

|

Simon S

|

| posted on 10/5/09 at 08:42 PM |

|

|

Transmission Woes

David,

Spotted you latest entry and it sounds like the UN1 'box has been keeping you entertained. You may recall I contacted you a while back because

I too want to run the UN1 inverted.

Is running the thing upside down what has caused your problems, or the amount of torque you are putting through it?

My own build progresses slowly, but I was still banking on the unturned UN1 idea. Any information would be gratefully received right now!

|

|

|

rpmagazine

|

| posted on 10/5/09 at 11:42 PM |

|

|

My project?...well slower than expected would be an understatement. Similar to you I have just started using my Rochdale Olympic, that and a job and

running Race Magazine means little time. So two months off work coming up just so I can get the chassis done and the engine in.

This is a project that has side lined me for a bit: carbon wings -

http://i129.photobucket.com/albums/p234/NRoshier/wingAS.jpg

[Edited on 11/5/09 by rpmagazine]

www.racemagazine.com.au

|

|

|

Dinoman

|

| posted on 22/5/09 at 10:15 AM |

|

|

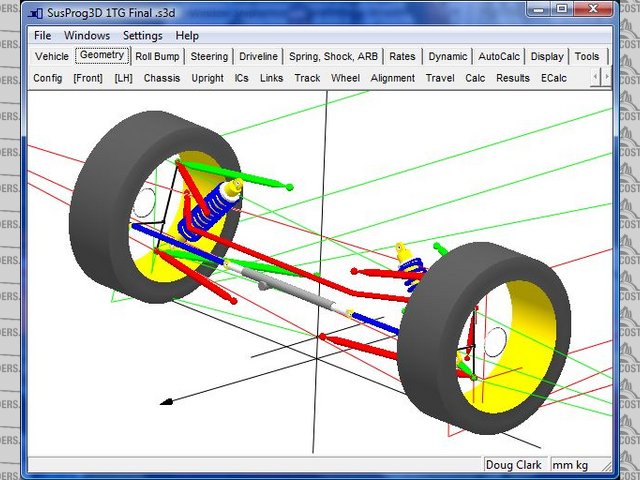

Hi I have just found this forum and just been reading this very interesting thread on suspension, the only reliable way to evaluate your suspension

geometry is to look at any Track type car that has to race against the clock and see he difference the tinyest of adjustments make to lap times,so all

I will add is if anyone is interested there is a very nice and cheap bit of Suspension Design Software for these wishing to know or learn developed by

Bob Small www.susprog.com check it out you can even download a trial version which allows you to get a feel for it efore you buy, Regards Dinoman

|

|

|

Benonymous

|

| posted on 26/5/09 at 06:56 AM |

|

|

That looks like a good program Dinoman, but I wouldn't call it Locost at US $215  I suppose if you were build ing from scratch, it could save

you a lot of headaches. I can't imagine anything worse than spending part of your life building a car to find out that it's an evil

handling bitch of a thing! I suppose if you were build ing from scratch, it could save

you a lot of headaches. I can't imagine anything worse than spending part of your life building a car to find out that it's an evil

handling bitch of a thing!

|

|

|

Doug68

|

| posted on 29/5/09 at 06:18 AM |

|

|

I own a copy of Susprog, its probably the most expensive software I've ever personally paid for!

I've used it on the design of the suspension for my car, I'd like to point out its not a panacea for suspension design you need to know what

your aims and goals are when using the thing.

So there's no guarantee you won't have designed a pile of poo even if you've invested a lot of hours in developing the suspension model

in the software.

Where it is very good though is sorting through the gazillion (technical term) iterations of design to get to the goals you seek.

The real brains though is working out what those goals should be in the first place, which as I've discovered in the process of designing the car

is by far the hardest part of the exercise because as you look further and further into it, it just gets more complex.

Where you draw the line in how much complexity you are prepared to deal with when you are designing suspension is entirely up to you.

Here's a picture of my front suspension in Susprog...

Rescued attachment Capture.JPG

Doug. 1TG

Sports Car Builders WA

|

|

|

Theshed

|

| posted on 29/5/09 at 03:48 PM |

|

|

I paid for Susprog too. I do not know where I would be without it. It is not cheap but its designer is a really good bloke - I have lost my password

about 6 times and he patiently sends me a new one.

It has a really useful function for locating chassis mounts in a way to limit roll centre movement - for those who believe in such things.......

It would be quite fun to run the standard "book" dimensions and see where things like roll centres bump steer etc came out.

|

|

|

rpmagazine

|

| posted on 6/7/09 at 11:36 AM |

|

|

more grist for the mill.

http://zzyzxmotorsports.com/library/roll-center-myths-and-reality.pdf

www.racemagazine.com.au

|

|

|

kb58

|

| posted on 7/7/09 at 01:39 PM |

|

|

My epiphany came after I realized that the traditional roll-center math ignores wheel load. In a turn, when RC location really matters, the inside

tire hardly has any load on it, right? Than why does that lightly loaded tire still have equal say in determining RC location? It can't...

The alternate methods by Mitchell and Ortiz, while they differ slightly, do take into account wheel loading.

[Edited on 7/7/09 by kb58]

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

rpmagazine

|

| posted on 9/7/09 at 12:00 PM |

|

|

your view of the tyre load is absolutely true for a car at max grip say on a dry skid pan at a constant speed or say at that section of a corner where

the same loads occur, which as you know will depend on the corner. Where this view falls down is of course at the section of the corner where the car

leads into and comes out of this dynamic situation, which is where the inner tyre is indeed important to consider...particularly if you consider such

things as swerve and recover situations.

Having said that we have to use the tools we have at hand, whatever this is. I'm tending to look at the geometric, then checking the FAP and

then doing a 'Beckman'...then relying on the advice of a pro!

[Edited on 9/7/09 by rpmagazine]

www.racemagazine.com.au

|

|

|

kb58

|

| posted on 9/7/09 at 02:35 PM |

|

|

quote:

Originally posted by rpmagazine

...Where this view falls down is of course at the section of the corner where the car leads into and comes out of this dynamic situation, which is

where the inner tyre is indeed important to consider...particularly if you consider such things as swerve and recover situations...

The only place both methods work identically is when the car isn't leaning, but the more the lean, the further away from reality the traditional

RC method gets. I agree it's not a lot for a swerving type maneuver, but since designers get all wound up about keeping their RC within

0.005" of perfect, it very much undermining what they think is perfection.

About "using the tools we have", I still am, I just modified mine

Mid-engine Locost - http://www.midlana.com

And the book - http://www.lulu.com/shop/kurt-bilinski/midlana/paperback/product-21330662.html

Kimini - a tube-frame, carbon shell, Honda Prelude VTEC mid-engine Mini: http://www.kimini.com

And its book -

http://www.lulu.com/shop/kurt-bilinski/kimini-how-to-design-and-build-a-mid-engine-sports-car-from-scratch/paperback/product-4858803.html

|

|

|

rpmagazine

|

| posted on 11/7/09 at 12:58 PM |

|

|

Oh sure, if you focus on one aspect thinking it the key to performance then you overlook how complex it all can be e.g. only looking at max cornering

can mean you design in 3 deg neg camber plus camber gain in bump/roll. Cool, you get good max G cornering, but then you loose out in less aggressive

cornering situations and your braking performance is compromised...flat spotted tyres get expensive and lose much performance.

www.racemagazine.com.au

|

|

|