jestre

|

| posted on 6/10/05 at 11:32 AM |

|

|

Alternative style wishbones

The book shows a picture of a set of wishbones that were bent. the shape was more of "U" shape rather than triangle. has any made a

set of these?

If so, could you help me out with the plans?

thanks

-Jess

|

|

|

|

|

ned

|

| posted on 6/10/05 at 12:10 PM |

|

|

if you mean the top front wishbones i think these are the mk style jobbies.

Ned.

beware, I've got yellow skin

|

|

|

jestre

|

| posted on 6/10/05 at 12:23 PM |

|

|

I'm looking for something like these. But, I would like the Bottoms to look like the tops.

still the MK styles?

|

|

|

ned

|

| posted on 6/10/05 at 12:28 PM |

|

|

there was a thread a while back (re racing iirc) about the curved mk bottom ones having an inherent weakness from the way the balljoint plate was

mounted to the curved wishbone tubes. i'll see if i can find it.

Ned.

not the thread i was thinking of, but check this one:

http://www.locostbuilders.co.uk/viewthread.php?tid=18432 it does go off at a tangent part way thorugh though.

think i found it:

http://www.locostbuilders.co.uk/viewthread.php?tid=12587

[Edited on 6/10/05 by ned]

beware, I've got yellow skin

|

|

|

britishtrident

|

| posted on 6/10/05 at 07:18 PM |

|

|

The better suppliers are now using designs similar to the one below (in this case from Marc Nordon Racing

http://www.mnrltd.co.uk/Suspension%20Components.html )

MK and GTS are similar (I would have use a GTS one an an illustration but Darrens web site seems to have more broken links each time I visit

it)

Rescued attachment front-lower-wishbone.jpg

|

|

|

britishtrident

|

| posted on 6/10/05 at 07:23 PM |

|

|

The matching top

[Edited on 6/10/05 by britishtrident]

Rescued attachment bushed-top-wishbone-new.jpg

|

|

|

907

|

| posted on 6/10/05 at 08:58 PM |

|

|

Hi

If the gusset plate on the bottom w/b is curved,

and the tube for the top w/b is bent to more or less the same angle,

they sort of match..... well nearly.

Paul G

Rescued attachment dlp-wb-up.jpg

|

|

|

Mark Allanson

|

| posted on 6/10/05 at 09:22 PM |

|

|

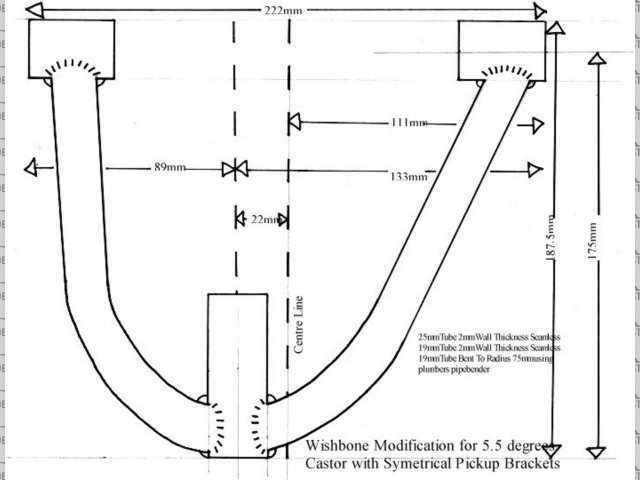

I made mine to this drawing using HB Cad, no problems at SVA on self centring

Rescued attachment Wisbone Modification.JPG

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

MikeRJ

|

| posted on 6/10/05 at 11:31 PM |

|

|

quote:

Originally posted by jestre

I'm looking for something like these. But, I would like the Bottoms to look like the tops.

still the MK styles?

You cannot have curved tubes on the bottom wishbones, this wishbone takes the majority of the load and curved tubes of reasonable diameter simply

wouldn't be strong enough. It's not ideal one the top one, but you can get away with it as the top 'bone is lightly loaded in

comparison. Generaly speaking bends are a very bad idea in any compressive/tensile load bearing member.

What is important is that the gusset plate where the shock bracket is mounted on the bottom wishbone is curved to avoid introducing a stress raiser

(unlike the ones shown ths far!). The GTS bones are very well designed.

|

|

|

britishtrident

|

| posted on 7/10/05 at 07:59 PM |

|

|

Curved tubes aren't a major problem on the either wishbone on the lower wishbone it is really case of getting detail design of the web plate

and is position correct but this adds weight. So the Vee design is more efficient and stronger.

On the top wishbone a curved design has the advantage of giving a better weld geometry for the top ball joint tube -- the book design is not the

easiest weld to finish properly when using MIG --- a TIG is a bit easier to get into the "V" . However the curved design will be a lot

less stiff and need heavier tube.

|

|

|

Bob C

|

| posted on 7/10/05 at 10:57 PM |

|

|

It's relatively easy to calculate the compressive load on the back tube of the lower wishbone while braking at 1G.

rearward force at lower balljoint is ~2x force at contact patch, for a 1/2 ton car thats ~200kgf (front remember, one side) This is shared between

tension & compression of front & back and divided by the cos of the tube angle: total say 350kg compression.

That's more weight than I'd like to put on a 20" long bent peice of 16s gauge tube. And that's before you add any cornering

forces or hit a kerb or add the bending moment due to the suspension unit.

I'd definately keep the bottom bones tubes straight. I'm keeping the top ones straight as well!!!

Bob C

PS feel free to disagree with the sums (like you need telling) - all approximations after wine AND whisky ;^)

|

|

|