smart51

|

| posted on 20/4/07 at 08:24 PM |

|

|

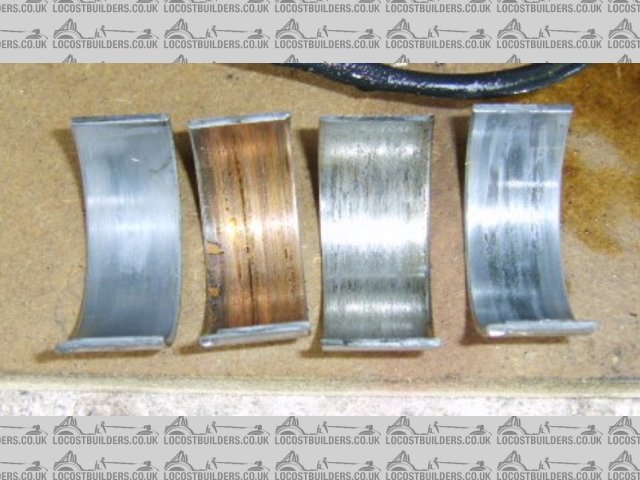

Well, I've separated the crank case halves and inspected the damage to the lower halves of all the crank shells. The crank case shells are fine

as are the outer two conrod shells. No 2 conrod shell has the first signs of wear, as does the crank, but No 3 shell is completely copper coloured

and worn. The crank also has traces of copper colour on it and signs of wear.

The crank from the old engine has been taken out and looks just fine. Tomorrow, at SWIMO's discression I'll take out the other and order

the apropriate new shells / gaskets etc.

I don't want to kill the new crank so how do I determine the cause of the failure?

|

|

|

|

|

tks

|

| posted on 20/4/07 at 08:30 PM |

|

|

mhhh

i would do another thing...

what was the problem with your first engine??

i woudn't touch that one and just swap from your new donor to the old donor if you get what i mean.

The reason is that crankcase bearings etc.. are atleast for me like walking on ice!

sow i would trow out the gearbox from the bad crankcase engine and put it in your old engine! think that atleast its less dangerous as

"playing" with crankcase bearings..

problems looks like oil pressure on that bearing #3...

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

smart51

|

| posted on 20/4/07 at 08:57 PM |

|

|

The old engine had the gearbox fixed, only to find that the piston skirts had worn, causing low compression. I think I'd rather swap the crank

than the pistons.

|

|

|

Coose

|

| posted on 20/4/07 at 09:27 PM |

|

|

Have you run it low on oil at all? I assume that you have a baffle plate? What kind of oil are you using?

The other thing to consider is that the motor will have most probably come out of a crashed bike, and who knows what happened just after the point of

impact? It could have easily been laid on its side with the throttle wide open for 30 seconds....

I'd do as you're doing - lob the crank in with new shells. It'd be nice to be able to blow out the oilways to be on the safe side,

but that'd mean a full engine rebuild which I think that you're trying to avoid.... Make sure that you assemble the shells with good

quality oil, and once it's rebuilt spin it over on the starter with the plugs out for a few seconds before starting it.

Spin 'er off Well...

|

|

|

smart51

|

| posted on 20/4/07 at 09:52 PM |

|

|

I have a baffle plate and the lowest it ever got on oil was the bottom of the sight window with the engine idling. I usually top the oil up once it

gets down to the middle of the window so that it just covers the window.

I've been using Castrol GPS semi-synthetic bike oil. Is this OK or should I be using fully synthetic?

The engine came from a trusted supplier of engines, not wanting to name names. He said it came from a known source. I don't know its origins

though. I don't want it to happen again as I'm fresh out of cranks so any suggestions of things to inspect would be welcome.

|

|

|

G.Man

|

| posted on 20/4/07 at 10:30 PM |

|

|

oil should be fine, failure almost certainly low oil pressure...

thats the only cause of main/big end/wrist pin bearing failure...

usually airlock in pickup, or oil level too low...

Opinions are like backsides..

Everyone has one, nobody wants to hear it and only other peoples stink!

|

|

|

Coose

|

| posted on 21/4/07 at 03:52 PM |

|

|

I think I can guess where your motor came from and there probably isn't anyone who is more reputable!

He would probably agree with me in what I said previously - the big end could have taken a beating during the last few seconds of the demise of the

bike that it came out of, but the damage may not rear its' ugly head until a short while afterwards, which I would suspect to be the cause of

the problem.

As stated in the previous post bu G.Man, your oil level should be ok, as would your choice of oil (though I personally use the best stuff I can get -

Motul 300V) so that *shouldn't* have contributed to the problem.

As I said before, I would do as you are planning to - fit the old crank with new big end and main bearings. It would also be worth flushing and

blowing out the oilways in the lower crankcase as that is where the crank is fed from. It should clear out any debris that may be left.

[Edited on 21/4/07 by Coose]

Spin 'er off Well...

|

|

|

smart51

|

| posted on 21/4/07 at 06:20 PM |

|

|

Here is a pic of the big end top shells. The bottoms are not quite as bad. I've ordered a complete set of shells plus all the gaskets bolts and

lock washers that are needed. £90. Plus oil and a filter. They should all arrive next friday.

I've checked all the oilways in the crank and lower crank case using spray carb cleaner (it comes out of the can with quite a lot of force).

They were all open and at 2 or 3mm diameter, it would take a lot of debris to block them. I've stripped the oil pump which looks fine too. Out

of paranoia, I might fit the pump from the old engine which has beautiful bearing shells.

Rescued attachment big end top shells.JPG

|

|

|

tks

|

| posted on 21/4/07 at 06:28 PM |

|

|

yeah

you can do that, saying that its wise to think about the fact where the worn piston skirt came from...

not that that second pump also has a problem...

saying that its stil strage that only num 3 looks that way...

i mean if the engine wouldn't get oil..

wy wouldn't all the bearings go out (with time) ??

To test the oil ways for obstruction i would try to measure how long it takes on each engine to empty if you fill it up with oil.. or whatso ever...

maybe its to to to to but atleast you can sleep relaxed

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

tks

|

| posted on 21/4/07 at 11:11 PM |

|

|

Thinking about your bad luck

guys what would happen if the engine's spark at no3 piston comes to early or to late would it be able to cause this kind of damage to the big

end??

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

Coose

|

| posted on 22/4/07 at 10:13 AM |

|

|

Doubtful, plus the fact that the pre-'02 R1 uses two coils, one for 1 & 4 and the other for 2 & 3, so the same would happen to 2 if that

was the case.

The problem is most likely oil starvation based on my previous posts.

Spin 'er off Well...

|

|

|

skydivepaul

|

| posted on 22/4/07 at 08:55 PM |

|

|

i had a total engine failure last year with an R1 and when i stripped it, it was No3 big ends that had seized also. these must be the first to

go????????

unfortunatley i couldnt salvage mine as it went whilst on a trackday at oulton park. i ended up with total engine failure, con rod snapped lots of

twisted metal and the like. it was horrible to look at

http://www.smartideasuk.com

http://www.smartmapping.co.uk

HD CCTV

3D design solutions and integration

IP security systems

access control systems

|

|

|

smart51

|

| posted on 6/5/07 at 05:32 PM |

|

|

Well, the engine is back together and I've done 4 short test drives totaling 20 miles. Apart from losing a little coolant, everything seems

fine. The engine sounds a lot quieter and smoother and purrs like a sewing machine. I've even found that cruising around in just sunglasses at

no more than 5000 RPM or 52MPH is fairly good, gentle fun. After a few more confidence building miles, I'll start to build up the revs and

throttle opening.

Next time, I'm going to build an EV.

|

|

|

locoboy

|

| posted on 7/5/07 at 06:44 PM |

|

|

Whats an EV?

ATB

Locoboy

|

|

|

smart51

|

| posted on 8/5/07 at 07:41 AM |

|

|

An Electric Vehicle. No oil leaks, no overheating, no big ends, no carbs. Just sealed for life roller bearings with a 10,000 hour life at rated

(read maximum) speed with no servicing required.

|

|

|

ChrisGamlin

|

| posted on 8/5/07 at 11:56 AM |

|

|

....with the performance of a milkfloat and 40 mile range

|

|

|